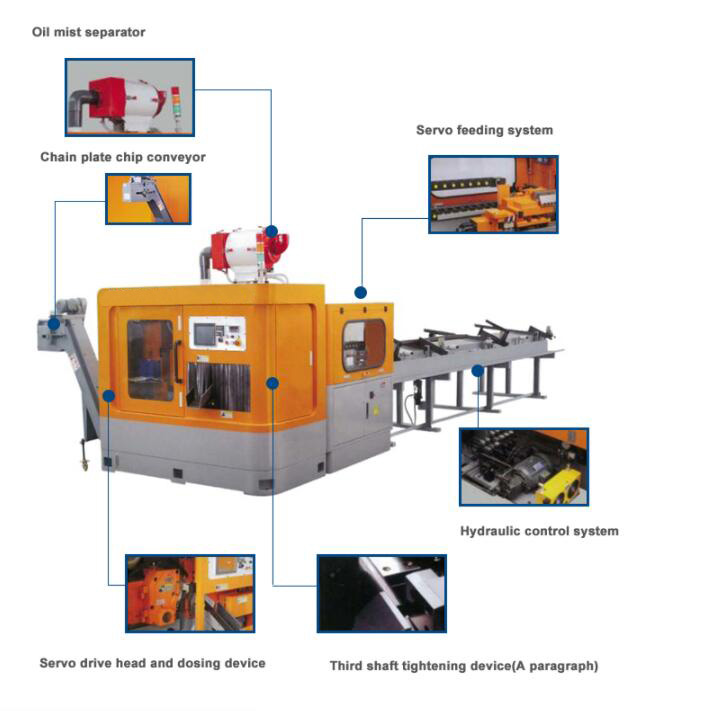

Automatic Pipe Cutting Machine * Automatic Servo Motor Feeding,Automatic Hydraulic Clamping and Automatic Hydraulic Cutting * Hydraulic driven saw head for cutting motion. * Servo Motor Feeding Transmission. * Interactive PLC touch screen offers easy access to auto and manual operating modes. ...... [Read More]

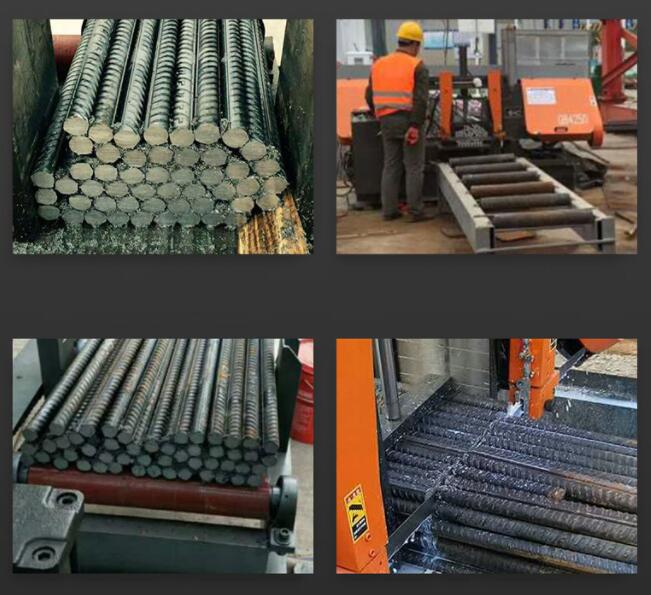

Circular Saw Machine For High Tensile Steel

Reported by: ANTISHICNC Date: November 18, 2021