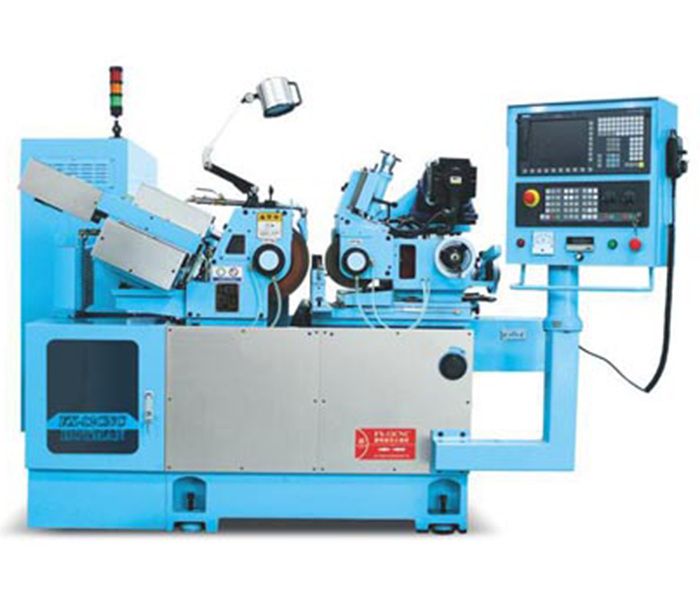

A centerless grinder is a type of grinding machine that does not require the positioning of the axis of the workpiece to perform grinding. It is mainly composed of three mechanisms: a grinding wheel, an adjusting wheel and a workpiece holder. The grinding wheel actually performs the grinding work, and the adjusting wheel Control the rotation of the workpiece and control the feed speed of the workpiece. As for the workpiece support to support the workpiece during grinding, there are several ways to cooperate with these three parts, except for stopping grinding, which are the same in principle.

1. The working principle of centerless grinder

A grinding machine that uses a centerless grinding method to grind the rotating surface of a workpiece, usually refers to a centerless cylindrical grinder. On a centerless cylindrical grinder, the workpiece does not need to be centered and supported by the center, but is placed between the grinding wheel and the guide wheel, and is supported by the pallet and the guide wheel. The grinding wheel is generally installed at the end of the spindle, and the grinding wheel with a width greater than 250 mm is installed in the middle of the spindle. The maximum width of the grinding wheel can reach 900 mm. The grinding wheel rotates at high speed for grinding, and the guide wheel rotates in the same direction at a slower speed, driving the workpiece to rotate for circular feed. During through grinding, the axial feed is achieved by adjusting the slight inclination angle of the guide wheel axis, which is suitable for grinding slender cylindrical workpieces, short shafts without central holes, and sleeve workpieces.

2. Features and advantages of centerless grinder

1. Suitable for the processing of complex and special-shaped parts

Centerless grinders can complete the processing of complex parts that are difficult or impossible to be processed by ordinary machine tools. Therefore, they are widely used in aerospace, shipbuilding, molds and other processing industries.

2. High processing accuracy

3. Stable and reliable processing

Computer control is realized, human error is eliminated, the processing consistency of parts is good, and the quality is stable and reliable.

4. high flexibility

When the processing object is changed, generally only the NC program needs to be changed, which shows good adaptability and can greatly save production preparation time. On the basis of a centerless grinder, an automated manufacturing system with higher flexibility-FMS can be formed.

5. High productivity

The centerless grinder itself has high precision, high rigidity, and can choose favorable processing amount. The productivity is high, generally three to five times that of ordinary machine tools. For the processing of some complex parts, the production efficiency can be increased by ten times or even dozens of times.

6. good working conditions

The centerless grinder is highly automated, the labor intensity of the operator is greatly reduced, and the working environment is better.

7. Conducive to management modernization

The use of a centerless grinder is conducive to the development of computer control and management of production, and the centerless grinder creates conditions for the realization of the automation of the production process.