Recently, the technical products department of an American archery company contacted us, hoping we could provide a lathe or Swiss-type CNC lathe machine to help them cut parts and chamfer the inner diameter. They needed to process hollow aluminum shafts for arrow shafts. They required the equipment to have automatic feeding and cut to a fixed length with a tolerance of +/- 0.1 mm.

This archery company is committed to providing innovative, high-quality products to enhance their customers’ sporting experience. After communicating with them, we recommended them with a suitable swiss type cnc lathe machine based on their needs: the G205 series swiss type cnc lathe machine from ANTISHICNC.

The advantages of this equipment include:

1.Extremely high precision and stability, allowing for complete composite machining in a single clamping operation.

2.Excellent efficiency, suitable for large-volume continuous production.

3.Powerful sub-spindle and power tools, giving it strong capabilities for complex part machining.

4.Can effectively save materials and costs.

5.Convenient automation integration, a natural automation platform that can help customers achieve long-term unmanned or minimally manned production, significantly saving labor costs.

The parameter informationof G205 Machine

| Specifications | Unit | G205 | Remark |

| Max. workpiece diameter | mm | Φ20 | |

| Spindle bore diameter | mm | Φ25 | |

| Max. workpiece length | mm | 2.5xΦD,Max. 50 | Without guide bushing |

| mm | 180/delivered in one time | Rotary guide bushing | |

| Max. spindle speed | r/min | 10000 | Rotary guide bushing 8000 |

| Spindle motor power | kW | 3.7 | |

| Spindle indexing | C-axis function | Continuous indexing | |

| Max. subspindle speed | r/min | 10000 | |

| Subspindle motor power | kW | 3.1 | |

| Subspindle indexing | C-axis function | Continuous indexing | |

| Max. radial live tool speed | r/min | 6000 | |

| Radial live tool power | kW | 0.75 | |

| Max. drilling diameter (main spindle/subspindle) | mm | Φ10 | |

| Max. tapping diameter (main spindle/subspindle) | mm | M10/M8 | |

| Max. drilling diameter (radial live tool) | mm | Φ8 | |

| Tapping diameter (radial live tool) | mm | M6 | |

| External turning tools | 1x□16+5x□12 | ||

| Facing tools | Pcs | 4(ER16) | |

| Radial live tools | Pcs | 2(ER11)+2(ER16) | |

| Back machining tools | Pcs | 4(ER16) | |

| Minimum resolution | mm | 0.001 | |

| Spindle runout | mm | <0.002 | |

| Repeatability | mm | <0.003 | |

| Rapid traverse speed | m/min | X1 axis: 20

Y1/Z1/X2/Z2 axes: 24 |

|

| Coolant motor power | kW | 0.4 | |

| Overall dimensions | mm | 2380*1300*1770 | |

| Machine net weight | kg | ≈2400 |

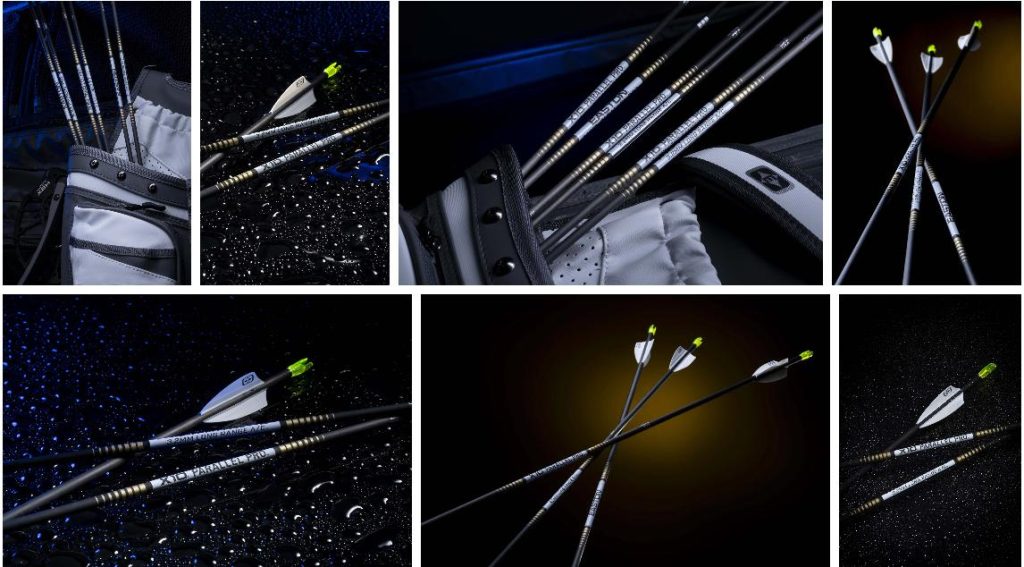

Customer workpiece picture:

If you have similar needs, please contact Shanghai ANTISHICNC: contact@antsmachine.com

We offer not only conventional lathes, CNC lathes, Swiss type CNC lathe machine, CNC lathe automation systems, vertical lathes, turning centers, and water-powered lathes, but we can also customize automated lathe production lines according to customer needs. Our technical team will definitely be able to provide you with the most suitable technical solution based on your requirements.

Keywords: Lathe, Conventional lathe, CNC lathe, Swiss type CNC lathes, CNC lathe automation, Vertical lathe, Turning center, Water-powered lathe, etc.