Recently, one of Shanghai ANTISHICNC Company’s end customers needed to purchase a vertical lathe to process the motor housing. The work-piece size required was: 800*800 mm. The inner diameter was 750 mm as shown in the figure:

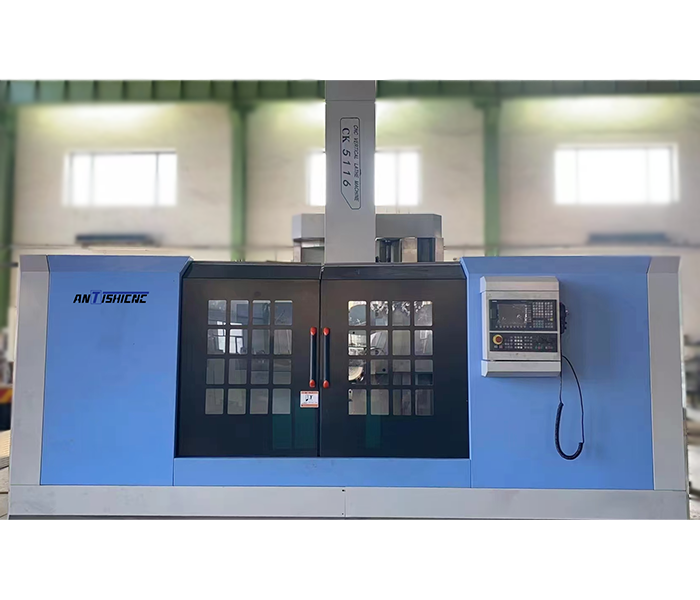

According to the customer’s needs, ANTISHICNC engineers successfully matched a CNC vertical lathe-CK5116D for the customer, with a maximum cutting diameter of 1600mm. The maximum height of the work-piece can reach 1000 mm. The weight of the work-piece is 5000 kg.

|

|

The workbench of CK5116D adopts dynamic pressure guide rail, long spindle structure, four-speed stepless spindle speed change, ordinary AC motor; square ram structure, ram vertical stroke is 1000mm; equipped with Siemens 808D system, semi-closed loop control.

The following are the basic parameters of CK-5116D:

| Specifications | Units | CK-5116D |

| Max. cutting diameter of the tool rest | mm | 1600 |

| Worktable diameter | mm | 1400 |

| Max. workpiece height | mm | 1000 |

| Max. workpiece weight | kg | 5000 |

| Worktable speed range | r/min | 6.2-200 |

Shanghai ANTISHICNC engineers will introduce you to the detailed processing process:

1.Preparation:

Familiar with the machining drawings and technical requirements of the motor shell, determine the processing technology and processing parameters.

Select the appropriate tools such as cutting tools, jigs and measuring tools, and check and debug.

Check and maintain the vertical lathe to ensure the normal operation of the equipment.

2.Workpiece clamping:

According to the shape and size of the motor shell, select the appropriate fixture for clamping.

Ensure that the workpiece is firmly and reliably installed, and will not be displaced or deformed during processing.

Find and position the workpiece to ensure the machining accuracy.

3.Tool selection and installation:

According to the processing technology and processing parameters, select the appropriate tool for machining.

Ensure the quality and accuracy of the tool meet the requirements, and carry out the correct installation and commissioning.

The cutting tool is pre-adjusted to ensure that the cutting edge height and Angle of the cutting tool meet the machining requirements.

4.Processing operation:

Start the vertical lathe for empty running and preheating to ensure the normal operation of the equipment.

According to the processing technology and processing parameters, roughing and finishing operations are carried out.

In the processing process, pay attention to observe the processing situation, timely adjust the processing parameters and tools, to ensure the processing quality and efficiency.

The motor shell after machining is measured and inspected to ensure that the dimensional accuracy, shape accuracy and surface roughness meet the technical requirements.

5.Cleaning and maintenance:

After the processing is completed, the vertical lathe is cleaned and maintained to remove impurities such as chips and oil.

Clean and maintain tools such as cutters, jigs and measuring tools to extend their service life.

Check and maintain the equipment to ensure the normal operation of the equipment.

Vertical lathes have broad application prospects in processing motor products. By improving processing accuracy and efficiency, adapting to motor products of different sizes and shapes, improving processing quality and surface finish, reducing processing costs and improving production efficiency, vertical lathes provide an efficient and reliable processing solution for the motor manufacturing industry.

If you have any questions, please contact Shanghai ANTS Machine Equipment Co., Ltd. through our website information. Engineers will match you with efficient machine tools and professional services.

Machine official website:

Application of single-column vertical lathe in the field of repair electric motors

Keywords: CNC vertical lathe, lathe processing, vertical lathe processing motor housing