With the rapid development of 3D printing technology, the importance of post-processing in improving product quality and production efficiency has become increasingly prominent. With its high-precision and high-efficiency cutting advantages, sawing machines have gradually become an indispensable equipment in the field of 3D printing. So, what are the specific applications of sawing machines in the field of 3D printing?

| Cutting printed substrate | Once 3D printing is complete, the print is usually attached to a substrate from which it needs to be separated. |

| Removing support structures | In the 3D printing process, some support structures are usually added to ensure the stability and molding quality of the model. After printing, these support structures need to be removed. The sawing machine can use its precise cutting ability to cut the support structure from the print without damaging the print itself. Compared with the traditional manual method of removing support structures, sawing cutting is more efficient and accurate, which can improve work efficiency and product quality. |

| Size Refinement | After forming, 3D printed parts may have dimensional deviations or uneven surfaces. The sawing machine can further process them to achieve higher dimensional accuracy and surface quality requirements. For example, for some parts with high dimensional accuracy requirements, such as parts in the fields of aerospace, automobiles, etc., the sawing machine can cut the printed parts to the exact size to meet the needs of practical applications. |

| Cutting special materials | With the development of 3D printing technology, more and more special materials are used in 3D printing, such as metal-based composite materials, ceramic materials, etc. These materials are difficult to cut, and traditional cutting methods may not meet the requirements. Saw machines can effectively cut these special materials by equipping them with suitable saw blades and cutting parameters, thus expanding the application range of 3D printing materials. |

| Parts repair and processing | 3D printed parts may be damaged or worn during use. The sawing machine can be used to cut out the parts that need to be replaced, and then re-manufacture the parts through 3D printing, and perform on-site repair or replacement, which greatly improves the operating efficiency of the equipment. In addition, for some complex-shaped 3D printed parts, subsequent processing may be required to meet assembly or use requirements. The sawing machine can be used in conjunction with other processing equipment to further process and improve the 3D printed parts. |

The following are the parameters of the 3D printed cutting saw:

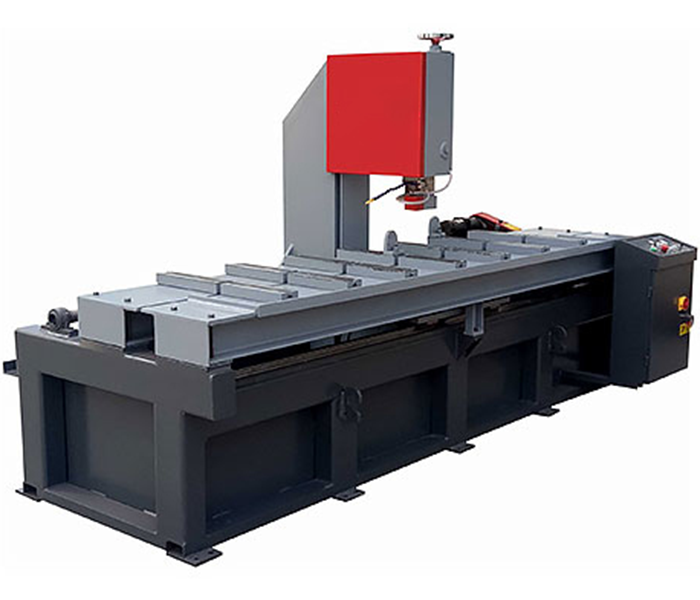

| picture |  |

| model | VS-500 |

| Applicable sheet size | 500×530 mm |

| Applicable Materials | inconel 718/625, stainless steel, aluminum, titanium, cobalt-chromium alloy, gold, silver, special alloys, rhenium alloy |

| Cutting capacity | |

| Cutting width | 500 mm |

| Cutting height | 520 mm |

| Technical Data | |

| Workbench size | 900 x 800 mm with 4 T-slots |

| Saw blade size | 5060 x 34 x 1.1 mm |

| size | 2070 x 1620 x 2542 mm |

| weight | 1500 kgs |

| Cutting speed | Continuous cutting (max. 750 m / min ) |

| Drive motor | 4.0 KW |

| Voltage | 400V 50Hz 3Ph |

If you also have 3D printing post-processing and cutting needs, please contact the Shanghai ANTS team. We will have professional staff to answer your questions and provide you with the right solutions.