First, let’s briefly introduce our best-selling M4 turret milling machine.

This vertical turret milling machine features a compact structure, small size, and high flexibility. The milling head can swivel 90° left and right, and tilt 45° forward and backward. The overarm not only extends forward and backward but also rotates 360° horizontally, significantly expanding the machine’s effective machining range.

The machine body is cast from SC250 cast iron, boasting a sturdy and non-deformable structure with excellent stability. The spindle is made of 40Cr alloy steel, subjected to quenching and tempering heat treatment as well as precision grinding. It is paired with a set of precision-grade angular contact ball bearings, ensuring strong cutting force and outstanding precision.

The three-axis angle seat nuts are made of high-grade phosphor bronze (PBC-2), offering good wear resistance and a long service life. The X/Y/Z axis guideways are all covered with TURCITE-B wear-resistant sheets, enabling easy operation, low wear rate, and long-lasting durability. Equipped with an upgraded electrical cabinet and control system, the spindle can be optionally configured with R8 or NT30/NT40 specifications. The overall performance is reliable, making it suitable for high-precision machining requirements.

With such an excellent M4 turret milling machine, what accessories does it have, and how powerful are these accessories? Let’s take a look together:

Ⅰ.3 axis DRO

The 3-axis Digital Readout (DRO) system is equipped with high-precision linear scales and a digital display unit, which can real-time monitor the displacement coordinates of the X, Y, and Z axes to achieve precise positioning and dimensional control. The DRO device features core functions such as absolute/incremental coordinate switching, metric/imperial unit conversion, preset zero point, and radius compensation. It supports data storage and program recall, significantly improving the efficiency and repeat positioning accuracy of complex contour machining.

The hardened box-way structure undergoes high-frequency quenching and precision grinding, and is paired with an automatic lubrication system to ensure long-term operational stability. It is suitable for milling operations requiring digital measurement, such as molds and precision parts, effectively reducing manual reading errors and serving as a key equipment in modern machining workshops.

Ⅱ. 3 axis auto feed

The 3-axis power feed is an automatic feeding device specifically designed for turret milling machines. It enables motorized feed control for the X, Y, and Z axes, significantly enhancing machining efficiency and precision.

This power feed adopts gear transmission or servo drive, with stepless adjustment of feeding speed and forward/reverse switching function, making it suitable for various machining needs such as milling, drilling, and boring.

Featuring a compact structure and easy installation, it can flexibly work with the swiveling milling head of the turret milling machine to expand the machining range. Equipped with an overload protection mechanism, it ensures stable and reliable cutting processes. It is particularly suitable for batch part processing, effectively reducing the labor intensity of operators while guaranteeing machining consistency and surface quality.

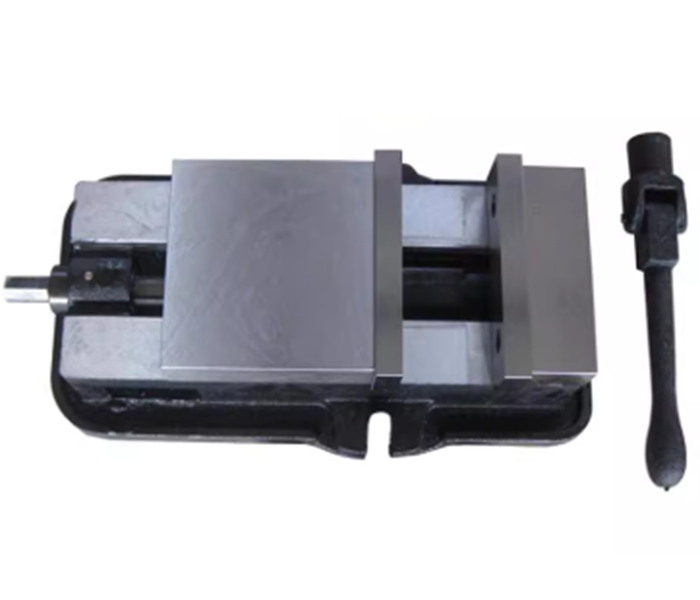

Ⅲ.6 inch Vise

The 6-inch bench vice is a high-precision fixture specifically designed for milling machine processing. With a jaw width of 6 inches (approximately 150mm), it can stably clamp small and medium-sized workpieces, making it suitable for various machining processes such as milling, drilling, and tapping.

This bench vice is made of high-quality cast iron or alloy steel and undergoes precision grinding treatment, ensuring that the parallelism and perpendicularity errors of the jaws are less than 0.02mm, thus providing reliable positioning accuracy. Its movable jaw design, combined with high-precision lead screw transmission, delivers strong clamping force while being labor-saving to operate. It is also equipped with quenched and hardened jaw plates, which are wear-resistant and anti-slip, effectively protecting the workpiece surface.

The base is equipped with standard T-slots, allowing for quick installation on the turret milling machine table. It supports 360° rotation adjustment to meet multi-angle machining needs, making it an ideal auxiliary tool for improving machining efficiency and precision.

Ⅳ.R8 collet set

The R8 collet set is a high-precision tool clamping system specifically designed for turret milling machines with an R8 spindle interface. It includes a variety of elastic collets in different specifications (commonly 1/16″-3/4″), which can be adapted to cutting tools such as straight shank milling cutters and drill bits of various diameters.

The collet body is made of high-quality alloy steel through heat treatment and precision grinding. The taper fit accuracy reaches 0.01mm level, ensuring that the radial runout of the clamped tool is ≤0.02mm. It comes standard with an anti-slip wrench and a tool unloading nut, enabling quick tool change and strong locking. Its internal thread pull rod structure can effectively transmit the spindle torque and prevent loosening during machining.

Suitable for high-speed milling (maximum speed 6000rpm) and heavy cutting conditions, it combines rigidity and precision, and is a core accessory for enhancing the versatility of turret milling machines.

Ⅴ.Clamping

The combination clamp is a modular fixture system specifically designed for clamping workpieces on milling machines. It consists of high-strength alloy clamps, T-bolts, stepped pads, and adjusting nuts, enabling quick positioning and rigid fixing of workpieces. This set undergoes quenching and hardening treatment, featuring strong deformation resistance with a maximum bearing pressure of up to 5 tons. When used in conjunction with the T-slots on the turret milling machine table, it can flexibly form various clamping schemes. The stepped pads support multi-level height adjustment from 5mm to 50mm, meeting the clamping needs of workpieces with different thicknesses. The locking nuts adopt an anti-loosening design to ensure no displacement during machining. It is suitable for milling, drilling, and other processes of irregular parts and large-sized workpieces, significantly improving clamping efficiency and machining stability, and is an essential auxiliary tool for processing complex parts.

In summary, professional accessories for turret milling machines form a modular system solution that comprehensively enhances machining efficiency and precision, including core components such as R8 collet sets, bench vices, 3-axis power feeds, and combination clamps. The R8 collet set ensures precise positioning of tools, the bench vice provides stable workpiece clamping, the 3-axis power feed realizes automatic feeding, and the combination clamp system expands the clamping capacity for large irregular parts. All accessories are made of high-quality alloy materials and manufactured with precision techniques, and can be quickly adapted to turret milling machines through standardized interfaces, forming a complete process chain covering tool fixing, workpiece clamping, and machining feeding. They can meet diverse machining needs from precision parts to batch production, significantly improving machining stability and consistency.

If you have similar needs, please feel free to contact Shanghai Ants Machine: contact@antsmachine.com. Our technical team will definitely match you with the most suitable technical solution.

Keywords: turret mill, turret mill accessories, 3-axis DRO, 3-axis power feed, collet set, bench vice, combination clamp