A vertical rotary table surface grinder typically features a vertically positioned grinding spindle and a worktable that is either adjustable or fixed. This type of grinder features a circular magnetic chuck worktable that rotates continuously. The workpiece is placed on the table and passes beneath the grinding wheel as the table rotates for grinding. Unlike horizontal rotary table surface grinders, which are primarily used for machining large components, vertical rotary table surface grinders are primarily suited for machining precision parts.

Vertical rotary table surface grinders are primarily used in the semiconductor and optical industries for grinding a variety of high-hardness, high-precision materials. Key applications include:

1.Semiconductor substrates and devices:Primarily used for processing silicon wafers, silicon carbide, aluminum nitride, alumina ceramics, iron-cobalt alloys, gallium arsenide, and wafer thinning machines.

|

|

|

| silicon wafer | silicon carbide | aluminum nitride |

|

|

|

| Alumina ceramic | Wafer thinning | Iron-Cobalt Alloy |

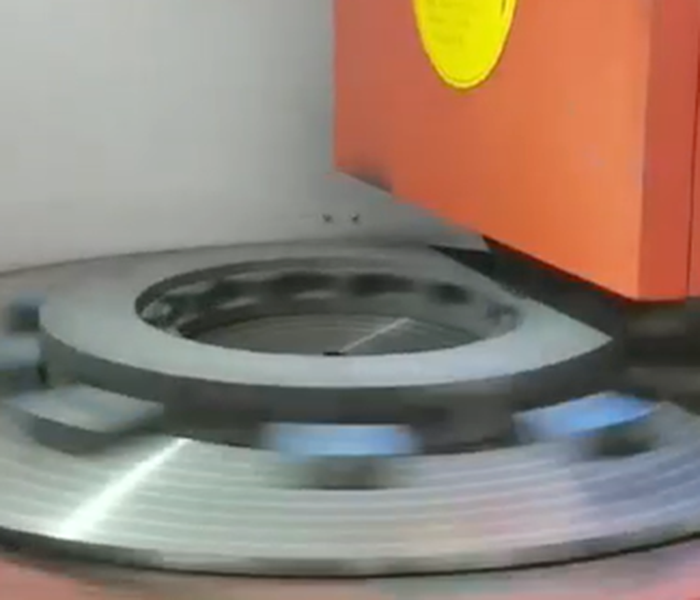

| Actual processing scene of the machine | ||

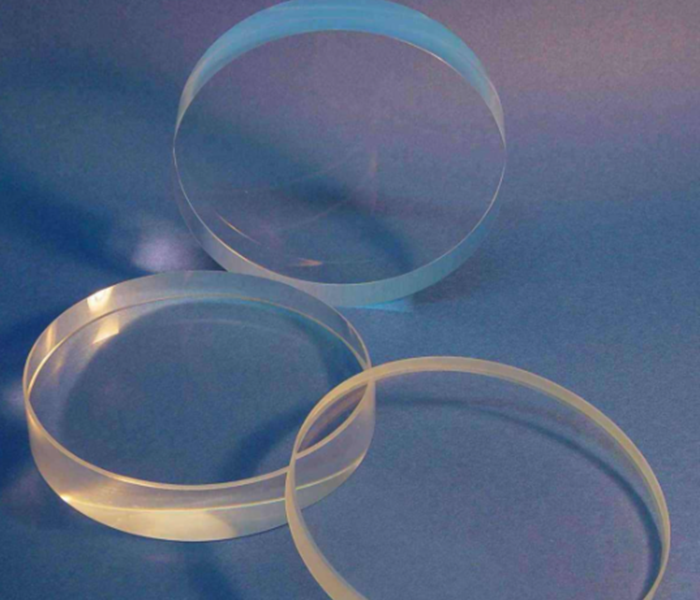

2.Optical components: optical glass (quartz glass, borosilicate glass), quartz, sapphire, and glass-ceramic.

|

|

|

|

| optical glass | quartz | optical prism | glass-ceramic |

| Actual processing scene of the machine | |||

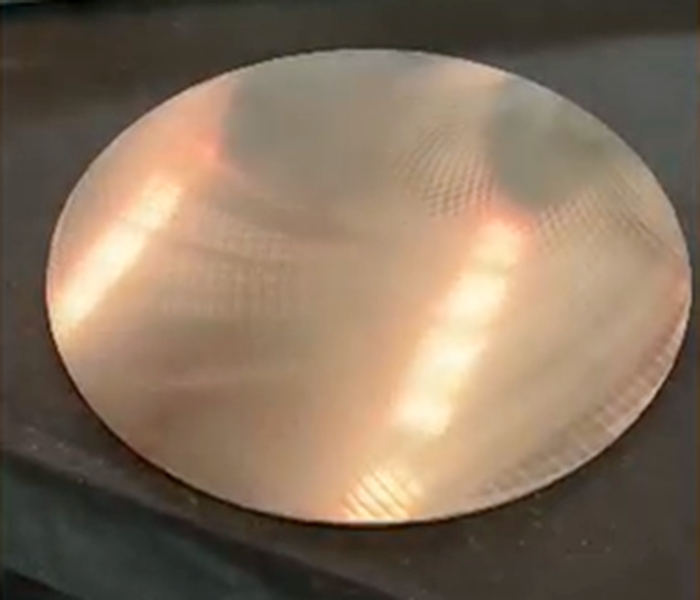

3.Precision parts for other industries: ceramic discs, carbon-carbon brake discs, pure tungsten discs, nickel-iron alloys, carbon fiber plates, magnetic steel, etc.

|

|

|

| ceramic piece | Carbon-carbon brake discs | Pure tungsten disk |

|

|

|

| Nickel-iron alloy | carbon fiber plate | magnetic steel |

| Actual processing scene of the machine | ||

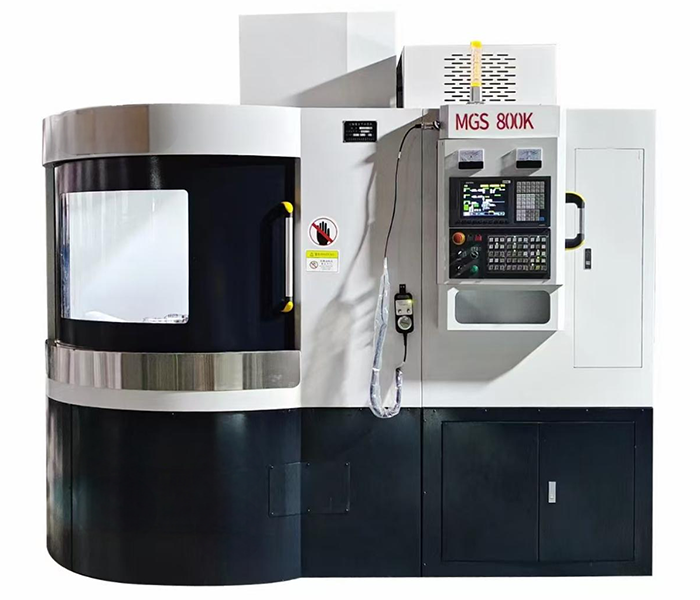

Recently, Shanghai ANTISHICNC Machinery Equipment received an inquiry from a foreign company that makes semiconductor-related accessories. The customer wanted to purchase an alternative to the Japanese rotary table surface grinder. After learning about the technical parameters of the customer’s benchmark product in detail, we recommended the MGS-800K to the customer, a CNC vertical spindle rotary table surface grinder with a worktable diameter of 800mm, which can fully meet the customer’s processing needs.

Shanghai ANTISHICNC CNC Vertical Rotary Table Surface Grinder MGS-800K

The machine’s main specifications are as follows:

| Parameters | Unit | MGS – 800K |

| Workbench diameter mm | mm | 800 |

| Electromagnetic workbench suction range | N/ cm2 | 150 |

| Maximum size of grinding workpiece (diameter × height) | mm | 800×300 |

| Maximum rotating diameter of worktable | mm | 800 |

| Workbench speed (frequency conversion) | rpm | 0. 3-10 |

| Diamond grinding wheel size (outer diameter × inner diameter × height) | mm | 450/Grinding wheel module |

| Workbench rotating motor power | KW | 2.2KW 1500rpm (with 1:60 reduction gearbox) |

| Grinding head spindle speed(frequency conversion speed regulation) | r/min | 500-960 |

| Grinding head fast moving speed | mm/min | 300 |

| Maximum vertical movement of grinding head | mm | 330 |

| Minimum vertical feed of grinding head | mm | 0.001 |

| Grinding head vertical feed rate | X1X10X100 | |

| Grinding head lifting servo motor power | KW | 1.3 |

| Grinding head motor power | KW | 11-4 |

| Water pump motor power | KW | 0.25 |

| Total machine power | KW | ≈ 15 |

| Machine tool dimensions (L x W x H) | mm | 2700x1600x2700 |

| Machine weight (approx.) | T | 6 |

If you also need a rotary table surface grinder, please feel free to contact Shanghai Antis. Our professional engineers can provide you with professional technical support.

Company email: contact@antsmachine.com.

Keywords: surface grinder, rotary table surface grinder, CNC rotary table surface grinder, programmable rotary table surface grinder, PLC rotary table surface grinder, optical rotary table grinder, semiconductor rotary table grinder, optical surface grinder, semiconductor surface grinder, vertical spindle rotary table surface grinder, horizontal spindle rotary table surface grinder