CNC hydraulic bending machine is a high-precision and high-efficiency metal processing equipment, mainly used for bending metal sheets. It realizes automated operation through computer numerical control technology and can process a variety of metal materials and complex shapes.

CNC hydraulic bending machine can process various metal materials, including but not limited to the following materials: carbon steel, stainless steel, aluminum and aluminum alloys, copper and copper alloys, galvanized sheet, titanium alloy, etc.

As an efficient metal processing equipment, CNC hydraulic bending machine can be used in different industries, as follows:

1.Sheet metal processing: chassis, cabinets, ventilation ducts, metal shells.

2.Automobile manufacturing: car doors, exhaust pipes, mufflers, frames, etc.

3.Aerospace: aircraft fuselage, wings, spacecraft shells and internal structural parts.

4.Building and steel structure: ceiling, steel beam, steel column.

5.Home appliance manufacturing: washing machine, refrigerator, air conditioner shell, metal bracket, metal pallet.

6.Power and energy: transformer shell, accessory box, solar bracket.

7.Shipbuilding: hull steel plate, deck, ventilation duct, drainage pipe.

8.Rail transit: train body and internal structure, rail model equipment bracket.

9.Furniture manufacturing: metal furniture, such as tables and chairs, metal doors, shelves, display racks.

10.Electronic products: computer case, server cabinet.

11.Agriculture and machinery factories: tractors, harvester parts, excavators, bulldozer parts.

Recently, an regular customer of Shanghai ANTISHICNC Machinery Equipment asked us if we have a suitable CNC hydraulic bending machine. The customer wanted to process a 2mm thick door and sent a workpiece drawing. Our professional engineer recommended the WE67K-160T2500 CNC hydraulic bending machine based on the customer’s drawings and workpiece materials. The engineer also provided professional mold drawings based on the customer’s sketches for the customer to choose different molds to improve processing efficiency.

|

|

|

|

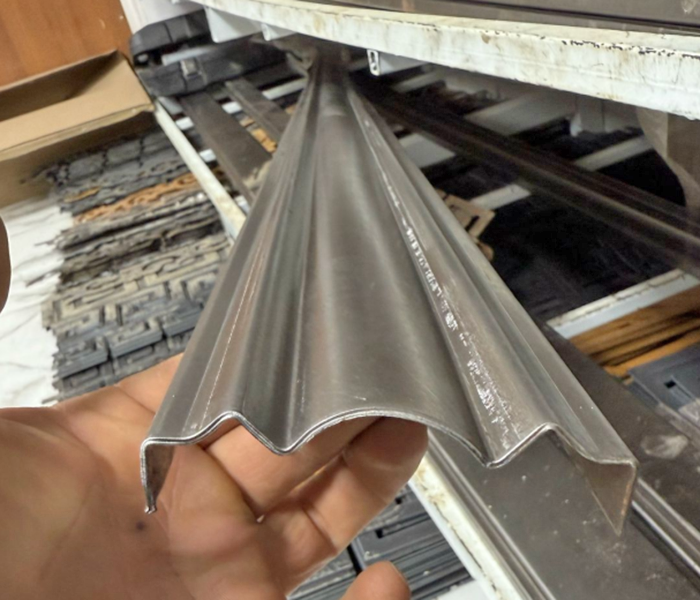

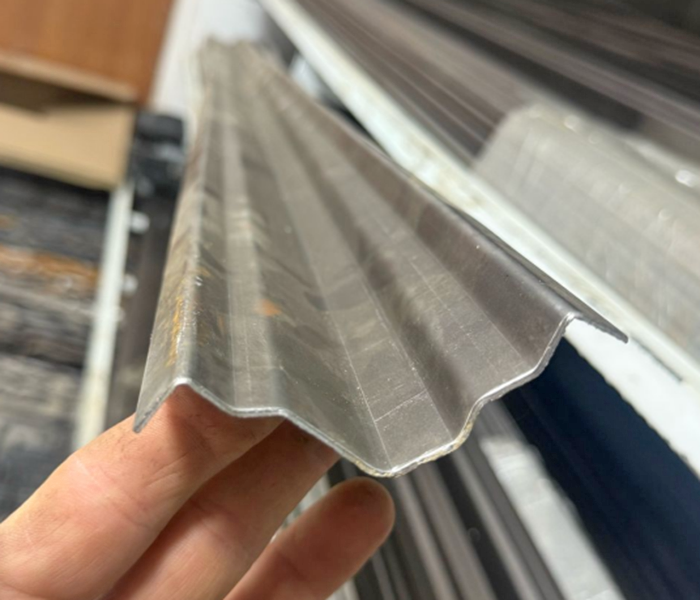

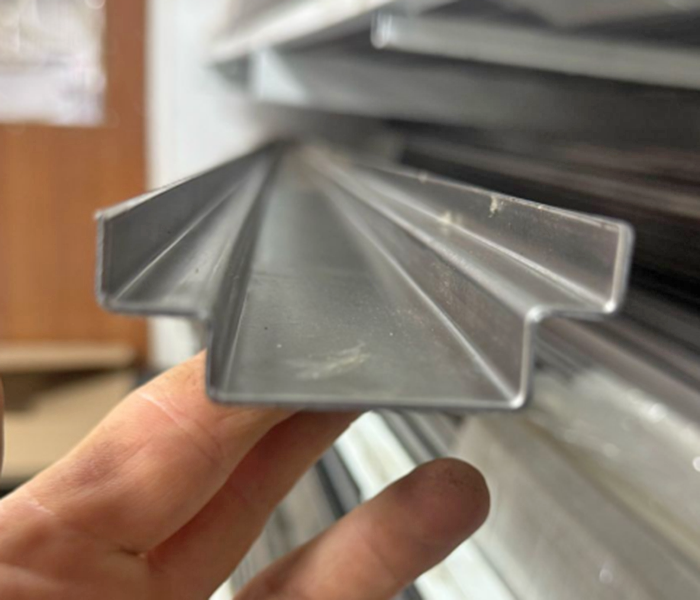

| The workpieces of client need to process | |

|

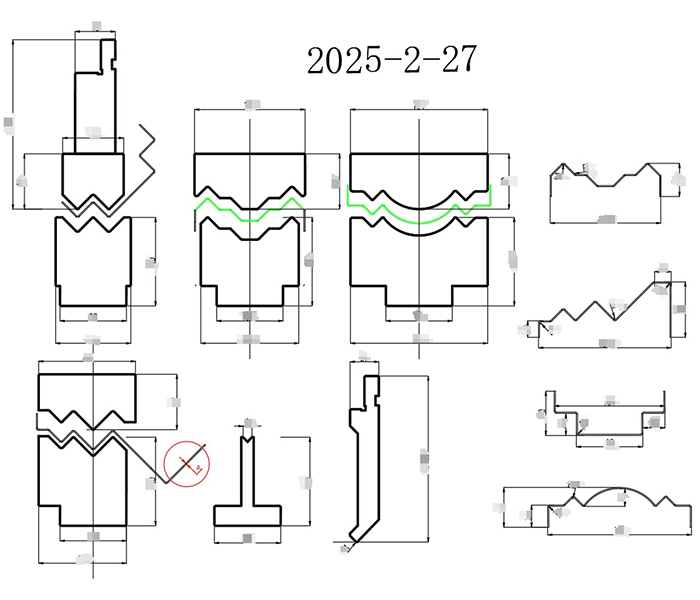

| Drawings made by engineers based on customer sketches |

E67K-160T2500 CNC hydraulic bending machine adopts the whole machine welding structure. The frame consists of left and right wall panels, workbench, oil tank, bracket, synchronous axis and slide block. 4+1 axis (Y1, Y2, X, R+compensation). The following are the specific technical parameters of this bending machine.

| Parameters | WE67K-160T2500 | Unit | |

| Nominal Pressure | 160 | Kn | |

| Length of Table | 2500 | mm | |

| Length of mold | 2500 | mm | |

| Distance between columns | 1900 | mm | |

| Throat Depth | 320 | mm | |

| Table height | 900 | mm | |

| Max. Open height | 420 | mm | |

| Back gauge X Axis | Range | 0-500 | mm |

| Max Run Speed | 360 | mm/s | |

| Position Precision | ±0.025 | mm | |

| Repeatability Position Precision | ±0.015 | mm | |

| Slider running speed | Range | 170 | mm |

| Position Precision | ±0.02 | mm | |

| Repeatability | ±0.01 | mm | |

| Y Axis | Repeatability | ±0.01 | mm |

| Main motor | 15 | KW | |

| Electric power supply | 380V 50HZ 3PH | ||

| Number of axis | 4+1 axis (Y1 , Y2 ,X,R +v ) | ||

| Overall Dimensions | L | 3100 | mm |

| W | 2100 | mm | |

| H | 2300 | mm | |

If you also have a need for a bending machine, please feel free to contact Shanghai ANTISHICNC. We have professional engineers who can provide you with professional technical support.