Press brake machines are used to bend metal sheets and shape work-pieces. The metal sheet is fixed by a clamping device and keep in original place throughout the processing . Press brakes can also use bending tools to shape the metal sheet to produce the required contour. CNC press brake machine can also use molds (general molds or special molds) to bend cold-rolled metal sheets into work-pieces of various geometric cross-sectional shapes. They are sheet metal forming machines designed specifically for cold-rolled sheet metal processing and are widely used in sheet metal bending processing in industries such as automobiles, aircraft manufacturing, light industry, ships, containers, elevators, and railway vehicles.

There are three main processes for sheet metal processing by press brake machine. Let’s take a closer look at each process:

1.Sheet metal programming

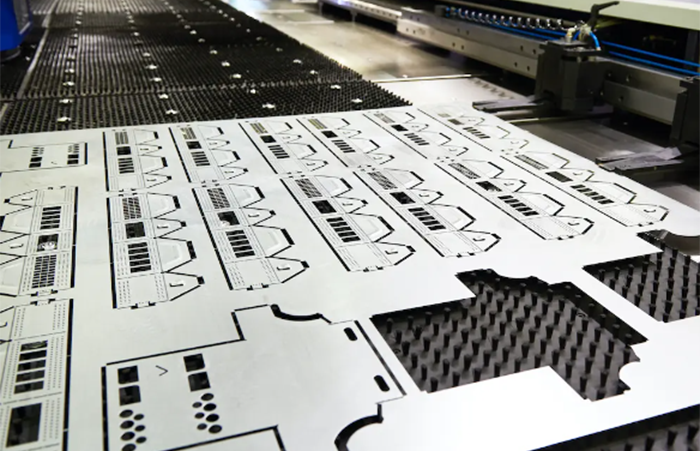

Design drawings are mostly drawn using 3D CAD, and sheet metal processing must be processed from a sheet so it is necessary to use CAD and special software to “expand” it into a sheet state before processing. Once the drawings are expanded, “layout” is performed, that is, the parts are laid out so that parts can be obtained efficiently from standard-sized materials without waste, and at the same time, the processing program is compiled.

2.Sheet metal cutting

In the process of cutting the outer periphery and inner holes of the blanking metal plate, the laser cutting machine and turret punch press are mainly used for processing. We can roughly distinguish that the laser processing machine is good at high-speed cutting of the outer periphery and large holes, and the turret punch press can also handle a large number of holes and forming processing. The equipment owned by each sheet metal factory is different. So if you are interested in laser cutting machines, you can also contact Shanghai ANTISHICNC Company to purchase.

|

|

Sheet Metal Processing With Press Brake Machine

The general bending process of mechanical sheet metal is to install the mold on a device called a plate bender and apply pressure to the cut plate to bend it linearly at a certain angle. In the press brake machine, the upper mold (convex mold) is installed on the upper part of the equipment, and the lower mold (concave mold) is installed on the lower part. The upper part of the equipment moves up and down to bend the metal plate, but the angle obtained by bending varies depending on the material batch and rolling direction, so fine-tuning is required each time, which makes processing difficult. In order to achieve high-precision and high-efficiency processing, many factories will use CNC press brake machines.

1) CNC press brake machines have a high degree of automation and intelligence. Through advanced CNC systems and programming software, operators can easily program and set processing parameters to achieve automated production. This not only greatly improves production efficiency, but also reduces errors and errors in human operations, and improves product consistency and stability.

2) CNC press brake machines have precise processing capabilities. The CNC system can control the position, movement speed and processing force of the upper mold, thereby achieving high-precision bending and bending operations. Whether it is a complex shape or a fine angle requirement, the CNC press brake machines can accurately achieve it, ensuring the quality and accuracy of the product.

3) The CNC press brake machines also have efficient production capacity. Due to the characteristics of automation and intelligence, the CNC press brake machine can complete a large number of processing tasks in a short time, greatly shortening the production cycle. At the same time, the CNC press brake machine is easy to operate, reducing the labor intensity of manual labor and improving production efficiency.

|

|

In the subsequent process, the difficulty and aesthetics of welding will change greatly due to the accuracy of the bending process. Therefore, bending is the most important process in sheet metal processing.

Keywords: Press brake machine, CNC press brake machines, Sheet metal processing