Turret CNC lathe, also known as CNC lathe, that is, computer numerical control lathe, is a kind of high-precision, high-efficiency automated machine tool. CNC machine tool is a mechatronic product integrating many technologies such as mechanical, electrical, hydraulic, pneumatic, microelectronic and information.

1.Lathe’s Turret Classification

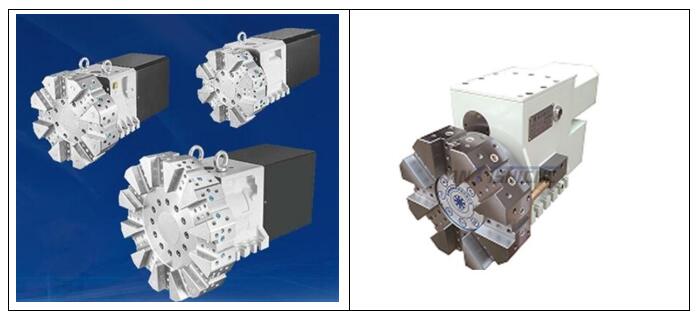

Lathe turret is generally divided into inline turret type and VDI type

①Inline tool turret

Straight insert tool turret is the tool is mounted directly on the tool holder, due to the straight insert turret intermediate adapter less, so the tool clamping rigidity is very good, but the tool change time-consuming. When selecting a tool, it is necessary to determine the form and size of the tool based on the width of the turret insert slot. When installing boring and drilling tools, an adapter is required. The tool holder is made from the boring, not interchangeable, the installation should be noted that must be on the machine tool, the tool number fitting. The dimensions of the boring and drilling tools should be referred to the form and size of the adapter tool holder, and the transition sleeve can be added if necessary.

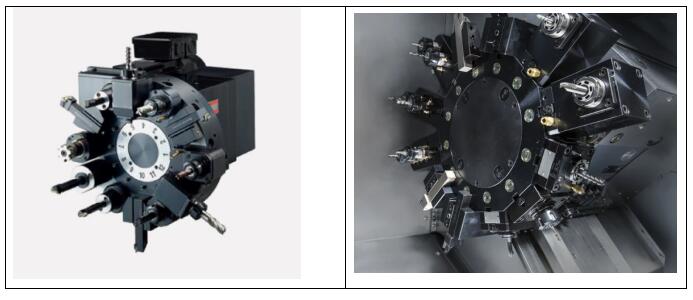

②VDI type tool turret

VDI-type tool turret is also known as a horizontal power turret. VDI refers to the way of loading the knife, it can not directly load the knife, but needs to use a variety of forms of VDI adapter knife seat. As these knife seats are mounted on the turret surface, so the cantilever is longer, and the rigidity is not as good as the direct insertion type. The VDI tool turret and knife seat interface is mainly based on the turret end face of the knife loading hole diameter to determine, such as the knife loading hole diameter of 40mm, then the VDI knife seat to choose the VDI40 interface. In addition, when selecting the tool holder, it should be noted that the VDI tool holder is divided into left and right tool holders, positive and negative tool holders, and so on. This is determined according to the orientation of the machine tool turret and the machining process. The right tool holder is selected for turret rear-mounted machines; conversely, the left tool holder. Forward and reverse tool holder. This is based on the orientation of the machine tool turret and the machining process to determine. Turret rear-mounted machine tool selection of the right tool holder; otherwise, the left tool holder. Forward and reverse tool holder selection must be considered at the same time two factors, namely, the front and rear of the machine tool turret and the spindle of the positive and negative rotation, must be correctly selected for normal use.

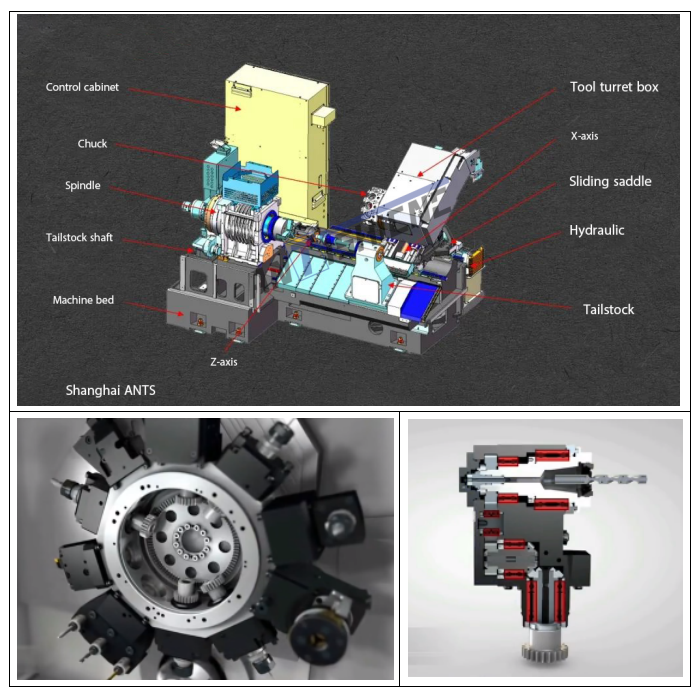

2. What is the working principle of a tool turret machine?

The turret adopts a single-action turret, which is rich in functions and can realize milling function. When working, the required tool will rotate to the No.1 tool position with the cutter plate, and the tool will realize the machining of the workpiece at the No.1 tool position; when applying the power tool, the power tool will only rotate when machining at the No.1 tool position, and the power tool at the other positions will not rotate, so it is less noisy, less energy-consuming, and has a higher efficiency and higher precision.

The linear rail part includes Z-directional linear rail, Z-directional slider, X-directional bed saddle, X-directional linear rail, and X-directional slider. There are two Z-directional linear rails. The two Z-directional linear rails are parallel to each other and fixed on the base. In part, there is at least one pair of Z-direction slide blocks. The pairs of Z-direction slide blocks are respectively arranged on two Z-direction linear rails and can slide back and forth along the Z-direction linear rails; the X-direction bed saddle is fixedly provided on at least one For the Z-direction slider, the X-direction bed saddle can slide back and forth along the Z-direction linear rail with the Z-direction slider. There are two X-direction linear rails. The two X-direction linear rails are parallel to each other and fixedly installed on the X-direction bed saddle. On the machine, there are at least one pair of X-direction slide blocks. The paired X-direction slide blocks are respectively arranged on two X-direction linear rails and can slide back and forth along the X-direction linear rails.

The tool holder part includes a main sliding plate and a single-acting turret. The main sliding plate is fixedly mounted on at least one pair of X-direction slide blocks. The main sliding plate can slide back and forth along the X-direction linear rail with the X-direction slide blocks. The single-action turret is equipped with There is a rotatable cutterhead, and a plurality of cutters are arranged on the cutter groove surface of the rotatable cutterhead.

3. Advantages of the tool turret machine

①The tool turret can be locked or disengaged while moving on the machine tool.

②The overload protection device in the turret can reduce damage to the turret in the event of a crash.

③The electric spindle speed can reach 5000 rpm.

④Only the tool in the processing position has the milling function.

⑤Suitable for mass production in production lines.

⑥When changing the tool, the cutter head will not lift up.

Shanghai ANTS Machine Equipment Co., Ltd. provides a variety of turret CNC lathe, automatic lathe, can support customized service, if you need, Please consult with our technical staff.

Keywords: turret lathe machine, CNC lathe