Cylindrical grinders are mainly used for precision grinding of end faces, outer circles and conical faces of batches of shaft parts, and are the main equipment in automobile engines and other industries.

It is also suitable for the processing of shaft parts with small batches and high precision requirements in military, aerospace, and general precision machining workshops.

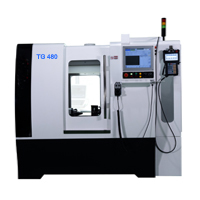

Surface grinder is a kind of grinder. The grinding wheel is mainly used to rotate and grind the workpiece to achieve the required flatness. According to the shape of the worktable, it can be divided into two types: rectangular worktable and round worktable.

The main parameters of the rectangular table surface grinder are the width and length of the table, and the main parameter of the round table is the diameter of the table. According to the different types of shafts, it can be divided into horizontal shaft and vertical shaft grinders.

When the workpiece is processed by cylindrical grinder, a rotating surface is obtained on the workpiece when the workpiece rotates around the axis with the cutter of grinding wheel.

Surface grinder is the workpiece for the table to drive translation movement, grinding wheel along with the workpiece movement direction into a certain Angle of the direction of translation, the result of motion synthesis is to cut a plane on the workpiece.