| Center-less grinding machine | External cylindrical grinding machine |

|

|

The main purpose of center-less grinders and cylindrical grinders is to grind the outer cylindrical surface of the workpiece to improve the dimensional accuracy, shape accuracy and surface quality of the outer cylindrical surface of the workpiece. Whether it is a center-less grinder or a cylindrical grinder, when processing shaft parts, it can process the outer cylindrical surface of the original blank of the workpiece to the size that meets the design requirements, and make the outer cylindrical surface smoother to meet the requirements of subsequent assembly or use.

So what is the difference between them? Please see the following information:

| Features | Center-less grinding machine | External cylindrical grinder |

| Processing range | 0.5-400mm | 1-1000mm |

| Machine structure | Grinding wheel frame, guide wheel frame, bed, work support | Machine Bed, grinding wheel frame, workbench, headstock, tailstock |

| Work principle | Supported between two grinding wheels by the outer surface of the workpiece | The workpiece is usually fixed in the center position by a combination of a chuck and a center. |

| Processing workpiece | Suitable for processing large batches of slender shafts and small diameter cylindrical workpieces

1. Shaft workpieces: slender shafts, cylindrical pins 2. Cylindrical sleeve workpieces 3. The outer diameter of screws and nuts 4. Small cylindrical hardware accessories 5. The handle of some tool workpieces |

More suitable for machining shaft workpieces with complex shapes and high precision requirements, especially those with a combination of steps, conical surfaces, etc.

1. Processing of complex-shaped shaft parts: stepped shafts, conical shafts; 2.Processing of large shaft parts: heavy machinery shafts, single-piece or small-batch shafts |

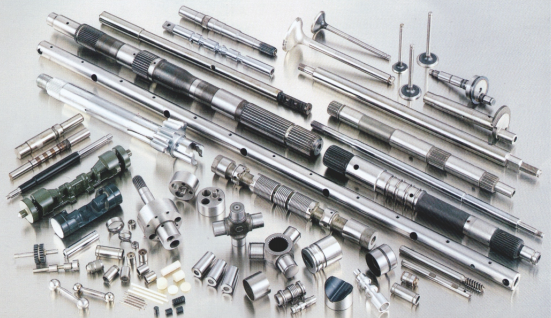

| Samples |  |

|

| Processing efficiency | Centerless grinders have significant efficiency advantages when processing cylindrical workpieces; they are suitable for mass production of single-specification workpieces: for workpieces with regular shapes, similar sizes and larger batches, centerless grinders are more efficient, and centerless grinders have the advantage of continuous automatic processing. High-speed grinding capability | When machining complex-shaped workpieces, such as shaft parts with multiple steps, conical surfaces or special curved contours, cylindrical grinders require a lot of time for clamping, positioning and precise adjustment of the grinding wheel motion path. This is a single-piece or small-batch machining process with low efficiency. |

| Processing accuracy | 1. Dimensional accuracy

Generally, the dimensional accuracy of a centerless grinder can reach about ±0.002mm, and the dimensional accuracy of a high-precision centerless grinder can be controlled within ±0.001mm 2. Shape accuracy Generally, the cylindrical accuracy can reach 0.0015mm – 0.003mm 3. Concentricity accuracy The concentricity error is generally between 0.002mm – 0.005mm 4. Surface roughness Ra0.16μm – Ra0.32μm |

1. Dimensional accuracy

External cylindrical grinder: The dimensional accuracy of ordinary external cylindrical grinders is about ±0.005mm, and the dimensional accuracy of high-precision external cylindrical grinders can reach ±0.0005mm or less 2. Shape accuracy The cylindricality accuracy can reach 0.001mm or less 3. Concentricity accuracy The concentricity error of high-precision external cylindrical grinders can be controlled within 0.0005mm – 0.001mm 4. Surface roughness The surface roughness of ordinary external cylindrical grinders can reach Ra0.32μm – Ra0.63μm, while that of high-precision external cylindrical grinders can reach Ra0.01μm or less |

| Processing cost | 1. Equipment purchase cost

The structure of the centerless grinder is relatively complex. It has a grinding wheel, a guide wheel, and a matching high-precision transmission and control system. In particular, the price of high-precision centerless grinders is relatively high. The price of ordinary centerless grinders may range from tens of thousands to hundreds of thousands of yuan, while the price of some high-precision, large-scale centerless grinders may exceed hundreds of thousands of yuan 2. Processing cost High processing efficiency leads to lower unit cost: Centerless grinders are very efficient in batch processing of cylindrical workpieces. Because it adopts a continuous automatic feeding processing method, once the parameters are adjusted, a large number of workpieces can be ground quickly. For example, when processing small cylindrical pins, the processing speed of the centerless grinder is much faster than that of the cylindrical grinder, which reduces the equipment depreciation, labor and other costs allocated to each workpiece 3. Tool (grinding wheel) cost The grinding wheel and guide wheel of the centerless grinder need to be replaced regularly, especially under high-load processing conditions. However, due to its processing method, the grinding surface of the grinding wheel can be reasonably utilized to a certain extent, and relatively speaking, the grinding wheel cost will not be too high in batch processing. 4. Maintenance cost The maintenance of centerless grinders requires professional technicians because the precision adjustment of the guide wheel and grinding wheel is high. The rubber binder and other materials of the guide wheel may wear or deform after long-term use and need to be replaced or repaired in time. In addition, the transmission system and control system of the centerless grinder are also relatively complex. Regular maintenance includes inspection, calibration and repair of these systems, and the maintenance cost is relatively high. |

1. Equipment purchase cost

The price range of cylindrical grinders is also relatively wide. The price of ordinary cylindrical grinders may be around tens of thousands of yuan, and the price of relatively simple small cylindrical grinders may be lower. However, for high-precision cylindrical grinders with complex functions (such as high-precision conical surface grinding, automatic compensation, etc.), the price will also be higher, up to hundreds of thousands of yuan. However, from the perspective of the overall equipment purchase cost, the price of cylindrical grinders may be slightly lower than that of centerless grinders under the same precision level and processing specifications. 2. Processing cost The relatively low processing efficiency may lead to higher unit costs: During the processing of cylindrical grinders, especially when processing single pieces or small batches of workpieces with complex shapes, it takes a lot of time to clamp the workpiece, center positioning and adjust the grinding wheel path. This makes the processing time of each workpiece longer, resulting in relatively high equipment use costs and labor costs allocated to each workpiece. 3. Tool (grinding wheel) cost The grinding wheel of the cylindrical grinder also needs to be replaced regularly, and when processing complex-shaped workpieces, the grinding wheel wear may be accelerated due to frequent adjustments to the grinding wheel path. For high-precision machining, more expensive grinding wheels may be required to ensure machining quality, which also increases machining costs. 4. Maintenance cost The maintenance of cylindrical grinders focuses on the replacement and calibration of grinding wheels, maintenance of centers and chucks, etc. Although its structure is relatively simpler than that of centerless grinders, for high-precision cylindrical grinders, maintaining the accuracy of the centers and ensuring the clamping accuracy of the chucks also require professional techniques and tools. In general, the maintenance cost of cylindrical grinders is slightly lower than that of centerless grinders. |

| Application Areas | 1. Mechanical manufacturing industry: widely used for grinding various shaft parts, such as crankshafts and camshafts of automobile engines, rotating shafts of motors, etc. These shaft parts require high dimensional accuracy and good surface quality, and centerless grinders can effectively meet these requirements.

2. Hardware processing industry: used for processing various cylindrical hardware accessories, such as external grinding of screws and nuts, and processing of small cylindrical pins and other parts. 3. Tool manufacturing industry: can grind cylindrical parts such as the handle of the tool to improve the manufacturing accuracy and quality of the tool. |

1. Mechanical manufacturing industry: used to process various shaft parts, such as crankshafts and camshafts of automobile engines, spindles of machine tools, etc.

2.Aerospace field: extremely high precision requirements for parts, cylindrical grinders are used to process the outer cylindrical parts of aircraft engine shafts, landing gear parts, etc. 3. Precision instrument manufacturing industry: when manufacturing shafts, rods and other parts of precision instruments |

If you need a centerless grinder, cylindrical grinder, or other grinders, please contact Shanghai ANTISHICNC: contact@antsmachine.com. Our technical team will be able to match you with the most suitable technical solution.

Keywords: Grinder, Centerless grinder, Cylindrical grinder, Cylindrical grinder