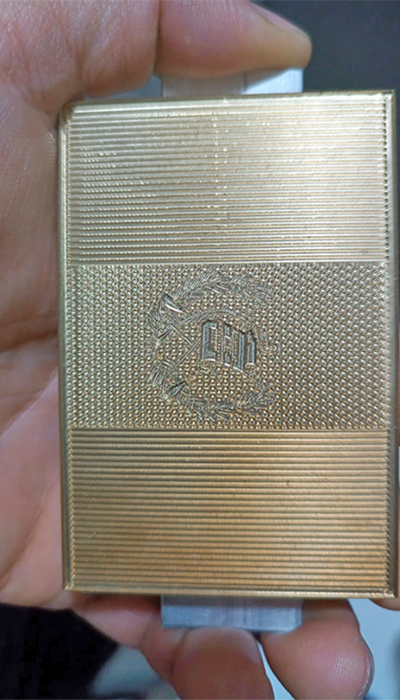

Recently, a Guatemalan end customer of Shanghai ANTISHICNC Company needed to purchase an engraving and milling machine to process commemorative badges. Engraving and milling machine is a CNC machine tool that combines engraving and milling functions. It is mainly used for high-precision, small cutting depth processing, and is suitable for fine engraving and light milling of metal and non-metal materials. Engraving and milling machine has the characteristics of high precision, high-speed spindle, light cutting and multi-function. Customer workpiece size: 5inch *5inch, 3D processing thickness is 0.3mm, the main material is bronze, and the entire edge of the material needs to be die-cut. The customer provided a photo of the workpiece to be processed, as shown in the figure:

|

|

According to the customer’s needs, ANTISHICNC engineers successfully matched a CNC engraving and milling machine for the customer: JD-4040. The maximum worktable size is 400*400mm. The maximum load-bearing capacity is 200kg. The following are the basic parameters of the JD-4040 CNC engraving and milling machine:

| Name | Item | JD-4040-3Axis |

| worktable | Size(W*L)mm | 400*400 |

| Max. Load weight(kg) | 200 | |

| Spindle | Spindle speed(RPM) | 24000 |

| Spindle power(KW) | 2.2 | |

| Effective feed stroke | X axis(Mm) | 400 |

| Y axis(mm) | 400 | |

| Z axis(mm) | 110 |

ANTISHICNC engineers will introduce you to the processing flow of JD-4040 three-axis CNC engraving and milling machine:

1.Design badge pattern

(1)Determine design requirements: clarify the theme of the badge (such as commemorative events, organizational logos, etc.), size (diameter is usually 20-50mm), shape (round, square or special shape) and surface effect (flat, relief, hollow, etc.).

(2)Use design software (such as AutoCAD, SolidWorks, CorelDRAW or professional engraving software ArtCAM) to draw the 2D or 3D model of the badge, paying attention to marking the size, engraving depth and detail requirements.

2.Prepare materials and equipment

(1)Select materials Common materials: metal (aluminum alloy, copper, stainless steel), plastic (acrylic, ABS), wood or resin, etc.

(2)Install tools and calibrate equipment to select appropriate tools according to design details

3. Engraving and milling processing

(1)Import program and test cutting

Import the generated processing code into the engraving and milling machine control system, and first perform dry run to check whether the path is correct to avoid collision or overcutting.

(2)Processing in stages

Roughing: Quickly mill out the general outline of the badge and the basic shape of the relief, leaving a 0.1-0.3mm finishing allowance.

(3)Finishing: Switch to a fine tool to accurately engrave details (such as pattern texture, text, and borders) to ensure a smooth surface and clear lines.

(4)Hollowing or drilling (if necessary): Use a small diameter tool to cut the hollow part or make a hanging hole.

4.Post-processing and finished products

(1)Deburring: Use sandpaper, polishing machine or chemical agents to remove edge and surface burrs.

(2)Polishing: Mechanically polish or electrolytically polish metal badges to improve gloss; plastic materials can be processed by flame polishing.

For more technical details and knowledge of CNC milling machines, please contact Shanghai Antis Machinery Equipment Co., Ltd. We provide customers with timely technical support, training and high-quality drilling machines.

Keywords: CNC machining, CNC milling machine, CNC milling machine processing commemorative badges