1.Different structural principles

The design principle of the two models is different, resulting in braking slider on both sides to ensure synchronization of different structures. Torsion axis bending machine is the use of torsion axis link left and right pendulum, the formation of torsion axis forced synchronization mechanism on both sides of the cylinder up and down, so the torsion axis synchronous press brake machine is a mechanical forced synchronization method, while the parallelism of the slider can not be automatically checked automatically mediate.

Electro-hydraulic synchronous bending machine is installed in the slider and the wall plate magnetic (grating) ruller, the CNC system can analyze the synchronization of the two sides of the slider through the magnetic (optical) scale feedback at any time, if there is an error, the CNC system will be adjusted through the proportional electro-hydraulic servo valves to synchronize the slider on both sides of the stroke. CNC system, hydraulic control valve group, magnetic scale constitutes the electro-hydraulic synchronous bending machine feedback closed-loop control.

| Torsion shafts for torsion shaft press braker machines | Grating ruller for electro-hydraulic press braking machines |

|

|

2.Workpiece precision

Slider parallelism determines the angle of the workpiece, torsion axis synchronous press braking machine is mechanical to keep the slider synchronized, there is no real-time error feedback, the machinery itself can not make automatic mediation. In addition, its partial load capacity is poor (torsion axis synchronous press braking machine is through the torsion axis to force the synchronization mechanism on both sides of the cylinder up and down movement, if the long-term partial load, will lead to deformation of the torsion axis)

Electro-hydraulic synchronous bending machine is the system through the proportional electro-hydraulic valve group to control the synchronization of the slider, magnetic (grating) ruller real-time error feedback, if there is an error magnetic (grating) rullere feedback after the system through the proportional valve to adjust to maintain the synchronization of the slider to improve the processing accuracy.

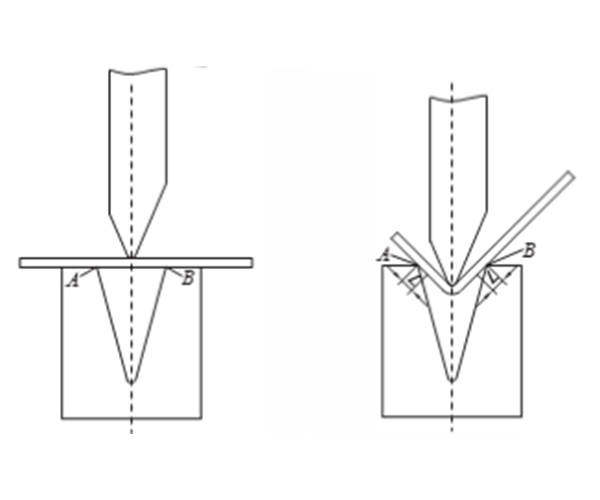

| Press Braking Process |

|

3.Running speed

There are two points in the work of the machine to determine its operating speed:

(1) The speed of the slider. (2) The speed of the backstop. (3) The bending steps.

Torsion axis synchronous bending machine selection is 6:1 or 8:1 cylinder, slow speed, while electro-hydraulic synchronous bending machine selection is 13:1 or 15:1 cylinder, fast speed. So the electro-hydraulic synchronous bending machine fast down the speed and return speed is much higher than the torsion synchronous bending machine.

| Machine | Oil cylinder | Fast and slow changeover | Fast down and return speeds | Backgauge running speed |

| Torsion Braking Machine | 6:1 or 8:1 | Not fluent | 80mm/s | 100mm/s |

| Electro-hydraulic Braking machine | 13:1 or 15:1 | Fluent | 200mm/s | 400mm/s |

4.Practical operation

Torsion axis synchronized CNC press braking machine because there is no configuration control system, not to mention the V-axis compensation, so when processing according to the drawings, we can only rely on the experience of experienced workers to put the sample to do the first test folding. If it does not meet the standards and continue to try, this process not only produces waste, but also the recruitment of operators to choose a small range, while high wages.

Electro-hydraulic synchronous press braking machine, is controlled by a professional CNC system, with V-axis compensation, easy to operate, low experience requirements for workers. There is a simulation bending function, do not need to release the sample, only need to correct the drawings to enter the size of the steps, directly bending.

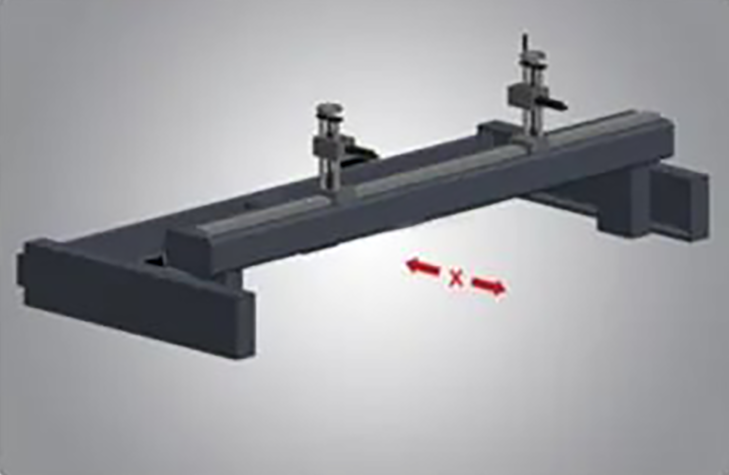

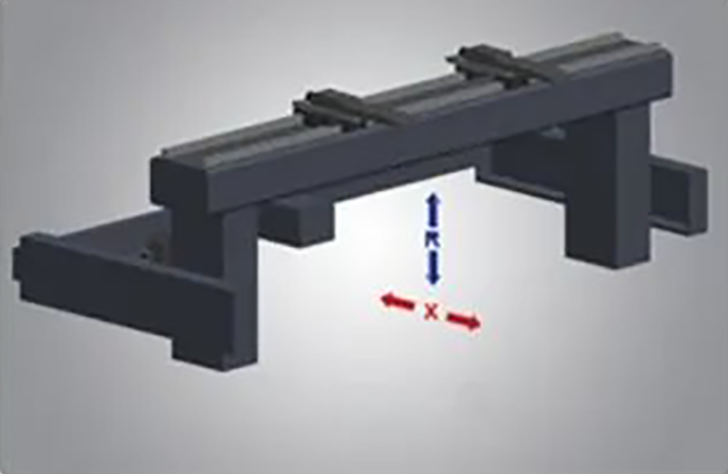

Optional manual compensation system for torsion axis bending machines (top right) Motorized axis compensation for electrohydraulic bending machines (bottom left)

5.Mechanical Strength

Because of the design of the machine, resulting in torsion synchronized bending machine can not be bias load bending, if long-term bias load bending will lead to deformation of the torsion axis. Electro-hydraulic synchronous CNC braking machine does not have such a problem, the left and right sides of the Y1, Y2 axis is independent of the operation, so you can bias load bending.

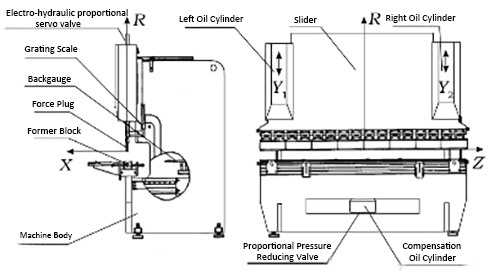

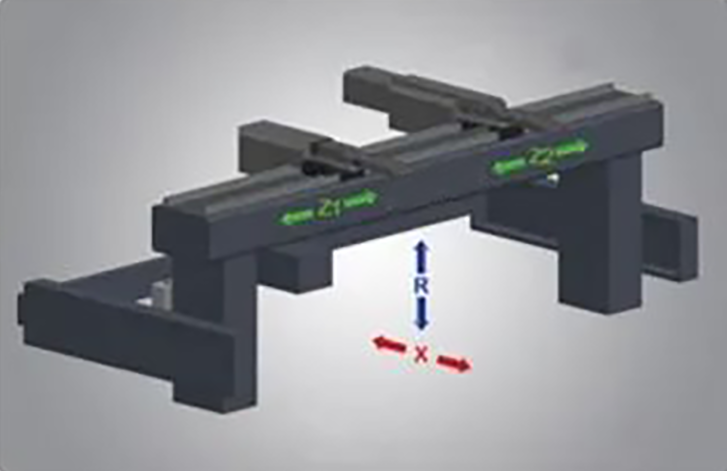

| Torsion shafts for torsion shaft press braking machines | Schematic diagram of electro-hydraulic press braking machine |

|

|

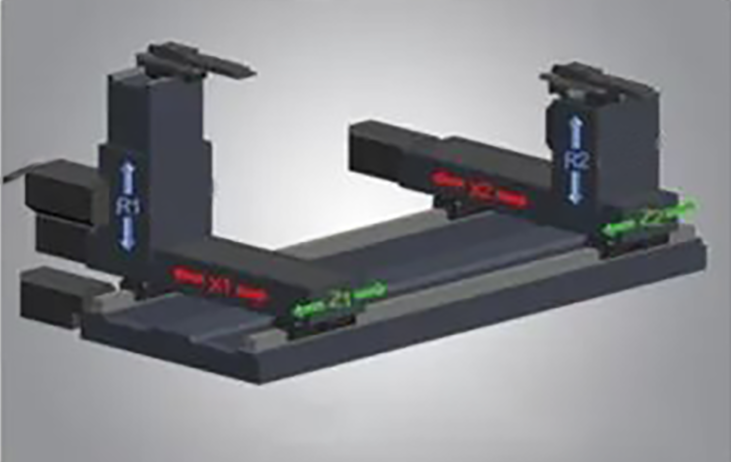

6.CNC axis

Torsion axis press braking machine control the more the number of axes the worse the effect, generally only control the X-axis and Y-axis. Electro-hydraulic press braking machine is not subject to the number of axes of the range of control, at least 3 +1 axis, that is, the automation program design can achieve high requirements, such as 4 +1 axis, 5 +1 axis, 6 +1 axis, 7 +1 axis, 8 +1 axis and so on. Multi-axis linkage processing, the workpiece in a bending machine after a clamping, can be automatic tool change, rotating spindle head, rotary table and other operations, to complete multi-process, multi-surface composite machining, not only high finish, but also a substantial increase in efficiency.

| Multi-axis options commonly used in electro-hydraulic press brake machines | |

|

|

|

|

Recommendations for the purchase of torsion bending machines and electro-hydraulic bending machines:

| Description/Machine | Twisted Shaft Press Brake Machine | Electro-hydraulic Press Brake machine |

| Precision | No high requirements for workpiece accuracy | High demands on workpiece precision and attention to detail |

| Capacity | Small amount of workpiece is required, and the working efficiency is not high. | High demand for workpieces and high requirements for work efficiency. |

| Operation | More manual operation is required, which is slightly inconvenient. | Intelligent CNC, full-featured, easy to use. |

| Applicable Company | New company, the initial period is mainly to feel and try | Large scale and big brand, output and quality are both important |

| Price | Lower price, some accessories need to be equipped separately | Higher price, but full-featured quality, overall cost-effective. |

Shanghai ANTS Machine Equipment Co., Ltd. provide a variety of Press Braker machines, can support customized services, if necessary, you can consult our technical staff.