Application of hydraulic bending machine:

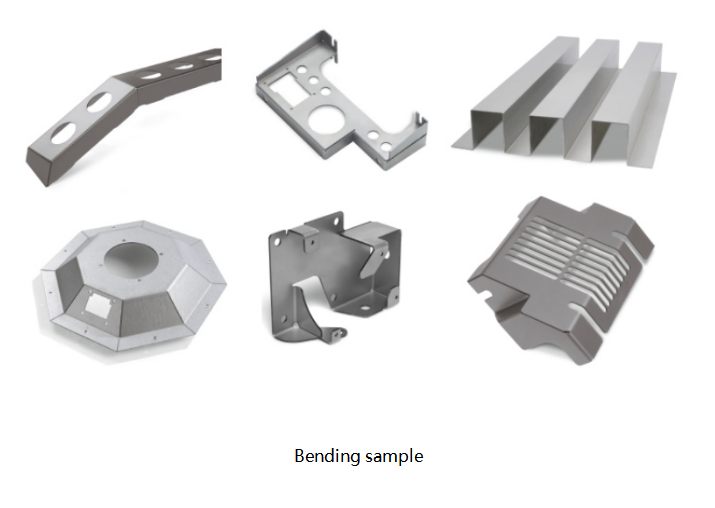

1. Hydraulic bending machine In the decoration industry, shears are widely used. They are generally used in conjunction with bending machines to complete the production of stainless steel plates, doors and windows, and the decoration of some special places;

2. In the electric power industry, the shearing machine can cut the plate into different required sizes, and then process it again through the hydraulic bending machine, such as computer cases, electrical cabinets, refrigerator air-conditioning shells, etc. are all made in this way;

3. Hydraulic bending machine is used in the kitchen and catering industry to process stainless steel kitchenware of various varieties and specifications, and then perform secondary processing, such as welding, bending, etc.;

4. In the wind power communication industry, wind power generation poles, road light poles, communication tower poles, traffic light poles, traffic signal poles, monitoring poles, etc. are bent;

5. Hydraulic bending machine In the automobile and shipbuilding industry, large-scale CNC hydraulic shearing machines are generally used, mainly to complete the shearing work of plates, and then perform secondary processing, such as welding, bending, etc.;

6. In the aerospace industry, high precision is generally required, and electro-hydraulic servo CNC bending machines can be selected.

Daily maintenance of hydraulic bending machine:

1. The hydraulic bending machine must be in charge of a special person, and the operator must be familiar with the use of the bending machine and safe operation knowledge.

2. The bending force of the hydraulic bending machine workpiece is not allowed to be greater than the nominal force.

3. In order to make the mold durable, it should not be damaged due to the short length of the bending sheet and the excessive pressure of the system. Especially when bending short sheets, the working pressure of the bending machine should be appropriately reduced to ensure that the length of the workpiece is The bending force of 100mm does not exceed 100kN.

4. Preliminarily adjust the gap between the upper and lower molds according to the thickness of the bent sheet. The gap can be about 1mm larger than the plate thickness, so that the mold will not be damaged due to too small a gap.

5. The bending sheet should be in the middle of the hydraulic bending machine. Generally, it is not suitable to be biased, so as not to affect the bending effect and the accuracy of the bending machine. If some workpieces do need to be processed on one side, the load should not be greater than four times the nominal force. One part, and the plates must be folded on both sides at the same time to prevent the hydraulic bending machine from being loaded on one side.

Tags: CNC hydraulic bending machine, CNC press brake, decoration industry, electric power industry, automobile and shipbuilding industry, aerospace industry