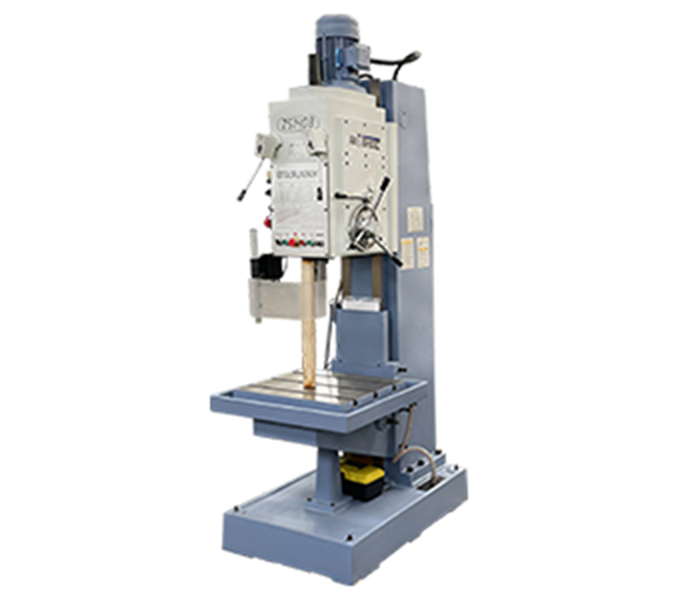

ANTISHI Z3132 universal radial drilling machine is used for small batch and single-piece production. It is one of the commonly used machine tools in the machinery manufacturing industry, especially the machinery maintenance department. The machine is flexible and man-hour saving, and is suitable for heavy machinery, machine tools, internal combustion engines, motors, shipbuilding and military industries. The machine tool is designed to be suitable for drilling, reaming, countersinking, plane and thread tapping at any angle on large and medium-sized parts, as well as for micro-milling of various planes before and after drilling. For processing extra large workpieces attached or hoisted on parts.

1. Z3132 Universal Radial Drilling Process Scope

The z3132 is designed to complete any angle hole machining in a variety of parts. Including drilling, reaming, reaming, countersinking, threading, etc. It is also required to be able to complete part of the process range that the end milling machine can complete, so as to meet the single needs of the machine tools in some repair factories.

Z3132 belongs to the radial drilling machine group. According to the design requirements, use a standard high-speed steel twist drill bit to drill holes on the medium tensile strength, the maximum hole diameter is 32mm, and the minimum hole diameter is 5mm.

2. Z3132 Universal Radial Drilling Degree of automation

In order to improve labor productivity, reduce the labor intensity of workers and better ensure machining accuracy and stability, machine tools should try to improve the degree of automation. However, the Z3132 drilling machine has a wide range of uses, and the workpiece changes greatly, so it is not easy to achieve full automation. At the same time, the design object of Z3132 machine tool is the machine repairing factory. Improving the automation of machine tools will inevitably increase the price of machine tools. This is not good for the sales of machine tools. Therefore, considering various factors, the feed system of Z3132 is designed as a motorized feed. So, manual micro-feed and rapid manual feed. The horizontal movement of the rocker arm is designed to be manual, the pinion rotation is realized by the rotation of the handle, and the horizontal movement of the rocker arm is realized by the rack and pinion transmission. After the rocker arm moves horizontally in place, it is also manually clamped. The main shaft rotates around the center of the column, and the main transmission shaft rotates around the center of the rocker arm. Since it does not move frequently, it can be planned by hand.

In order to adapt to the flexibility of the machine tool, the machine tool is not fixed on the foundation, and four jacks are set under the machine tool. Just touch the ground to support the machine with four jacks. Install rollers under the machine. When moving the machine tool, only the rollers need to touch the ground and the machine tool can be pushed manually.

3. Z3132 Universal Radial Drilling Machine tool life

As for the life of the machine tool, since Z3132 is a small general-purpose machine tool, its life is required to be about 8 years. The life of gears and bearings in the machine tool is set as T=15000 hours. Rolling bearing T=10000 hours. To ensure the life of the machine tool, it is mainly to improve the wear resistance of key parts. And correspondingly improve the fatigue strength of the main parts.