Lathes are the most widely used type of machine tool in manufacturing. The main components of the lathe are head stock, feed box, lead screw and smooth bar, slide box, tool rest, tail stock, bed, cooling device. A type of machine tool that uses the spindle to drive the work piece to rotate as the main motion, and the tool holder drives the tool to move as the feed motion to complete the relative motion between the work piece and the tool. It is mainly used to process various revolving surfaces, such as inner and outer cylindrical surfaces, conical surfaces, forming revolving surfaces and end faces of revolving bodies, etc. Some lathes can also process threads.

The tools used on the lathe are mainly turning tools, and some lathes can also use various hole processing tools, such as drills, boring tools, reamers, taps, die and so on.

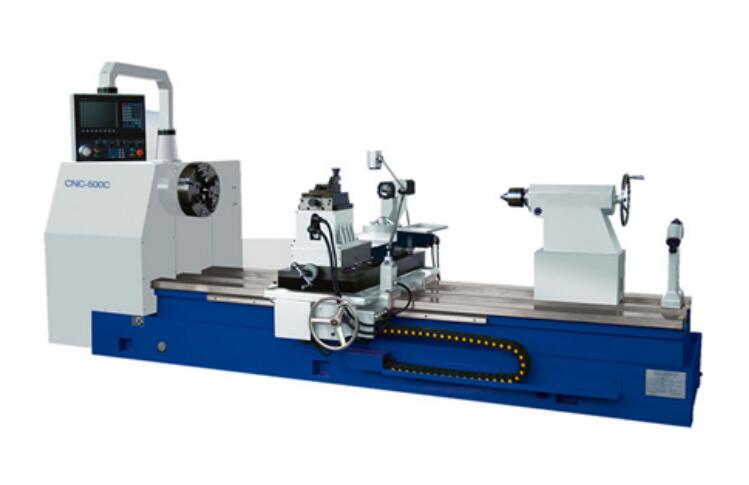

The types of lathes are: horizontal lathes and floor lathes, vertical lathes, turret lathes, single and multi-axis automatic and semi-automatic lathes, copy lathes and multi-tool lathes, CNC lathes and turning centers, various specialized lathes(crankshafts, camshafts, shovel tooth lathes, wheel lathes, etc.)

Among them, the horizontal lathe has the advantages of simple structure, convenient operation, large spindle diameter and small footprint, and is suitable for the machine and instrument industry as the processing of small mechanical parts and repairs.

Floor lathe features is no bed, tails tock, no lead screw; suitable for turning 800-4000mm large diameter, short length, light weight disc, annular work piece or thin-walled cylindrical, as well as various tire molds, Work pieces such as large diameter flanged tube sheets.

Vertical lathes, mainly single-column type and double-column type, are generally used for machining work pieces with large diameter, short length and high quality. The table of the vertical lathe is horizontal, the axis of the spindle is perpendicular to the table, the work piece is corrected, and the clamping is more convenient. The weight of the work piece and the table evenly acts on the circular guide under the table.

Turret lathe (turret hexagonal lathe) In order to meet the needs of mass production of parts with complex shapes, a turret lathe was developed on the basis of horizontal machine tools. Compared with the horizontal lathe, the main difference in structure is that the turret lathe does not have a tail stock and a lead screw, and a longitudinally movable multi-station turret tool post is installed at the tail stock position, and multiple turrets are installed on the tool post cutter.

Shanghai ANTS focuses on taking the road of high-precision scientific and technological innovation, becoming a leader in China’s sawing and lathe industry, and a pioneer in the world’s lathe manufacturing. In the early days of the company’s establishment, it actively absorbed the world’s advanced technology such as Germany, Japan, and the United States, and focused on research The development of processing technology and related processing technology, dedicated to the application of new concepts, new thinking and new technologies. The company is mainly engaged in universal lathe, CNC lathes, heavy-duty lathes, special purpose lathes and other equipment. The products are deeply trusted by customers and are exported to more than 20 countries and regions such as the United States, Germany, Italy, India, Thailand, Russia, etc., and established in many countries. It has a perfect sales channel and service network, and has the characteristics of rich experience, excellent manufacturing and professional service in the same industry in China.

Shanghai ANTS has strong technical force, sophisticated production equipment, advanced production technology, high-quality workforce and a complete after-sales system, If you want to know more about ANTISHI, please visit our official website.

Our website:http://www.antsmachine.com

If you have any other questions, please contact us directly by email.

Our email: Contact@antsmachine.com