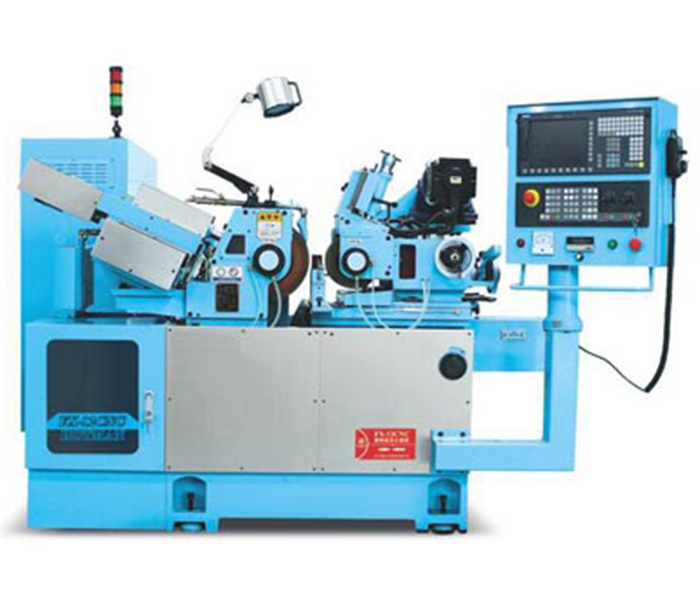

Spindle start and brake time is too long or no brake The starting time of the main shaft is too long. Mainly check the performance of the inverter and whether the parameter settings are reasonable. Focus on checking the starting frequency, starting mode and acceleration/deceleration time setti...... [Read More]

What should I do if the braking time of the spindle of the CNC lathe is too long?

Reported by: ANTISHICNC Date: November 3, 2021