At present, when the thread rolling machine performs thread rolling operations on the threaded rods, it is necessary to manually place the threaded rods one by one between the thread rolling dies of the thread rolling machine. Due to the use of personnel, the labor intensity of the workers is high. And the production efficiency is low,

In addition, manual operation is adopted. If the operation is negligent, it is easy to cause the operator to be injured. Therefore, it is necessary to design an automatic feeding device to overcome the above drawbacks.

Design of automatic feeder for grinder and automatic thread rolling machine

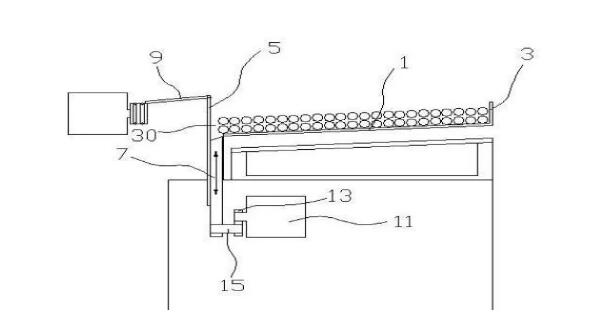

A material plate 1, an annular side wall 3 that surrounds the periphery of the material plate 1 and extends upward, and the left side of the annular side wall 3 is provided with an opening 30, and the material plate 1 is inclined to the left so as to be placed on the material plate The tooth bar on 1 can slide out from the opening 30. A baffle 5 is also provided on the left side of the material plate 1, and a slider 7 is also provided between the material plate 1 and the baffle 5. The upper end surface of the slider 7 is also inclined to the left. The driving device for the up and down movement of the block, the side of the baffle 5 is also provided with a conveyor belt 9. The driving device for moving the slider up and down includes a motor 11, and a turntable 13 is provided on the shaft of the motor 11, and a pin 15 is penetrated on the wall of the turntable 13, and the other end of the pin 15 is penetrated On the side wall of the slider 7. 、When using, place the tooth bar on the material plate 1. As the material plate 1 is tilted to the left, the tooth bar slides to the left and slides into the upper end of the slider 7 from the opening. The motor 11 rotates at this time. , The slider 7 is raised. When the slider 7 is higher than the conveyor belt 9, the upper end surface of the slider 7 is also inclined to the left. Between rolling dies. As a result, the utility model realizes automatic feeding, greatly reduces the labor intensity of workers, and greatly improves production efficiency. In addition, due to the automatic feeding, the processing is continuous and the product quality is stable.

It can also be used on centerless grinders and other equipment, so that automatic feeding of centerless grinders can be realized.