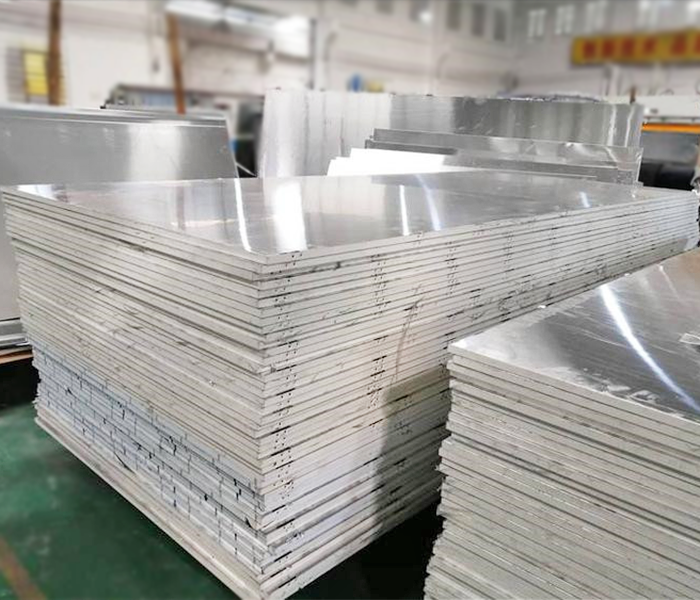

Aluminum honeycomb composite panel is a new type of composite material with sandwich structure, adopting hot press forming technology, which consists of upper and lower layers of aluminum plate (high-quality 3003H24 alloy aluminum plate or 5052AH14 high-manganese alloy aluminum plate) compounded with aluminum honeycomb core through adhesive or adhesive film and is widely used in the fields of construction, aerospace, transportation, solar power generation and so on.

Recently, the Shanghai ANTISHICNC team received an inquiry from a construction company. The customer needs to process aluminum honeycomb composite panels with a length of 3200mm, a width of 1500mm and a thickness of 50mm, and requires a machine with a heating function and a moving table.

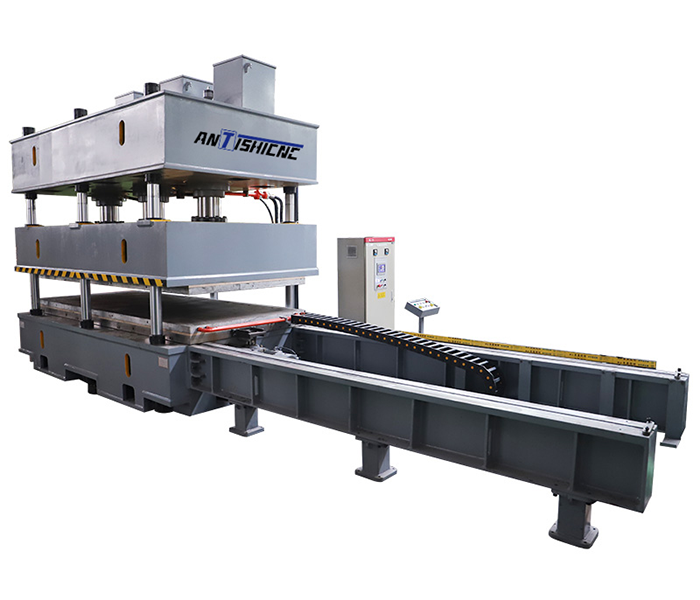

According to the customer’s needs, we recommend the following 500 tons hydraulic press machine for aluminum honeycomb composite panels.

500 tons aluminum honeycomb composite panel hydraulic press machine is mainly composed of main machine, hydraulic control system, electrical control system, lubrication system and safety protection system.

Overview of the main components of the machine

1.The main machine is in the form of three-cylinder column structure, the three beams are made of high-quality steel plate welded by carbon dioxide shielding welding and then tempered to eliminate internal stresses, so that the structure is more stable, not easy to deform, and has a long service life.

2.The size of the working table is 3600x1600mm, the working table is large and the force is even.

3.The column is made of high quality round steel which is polished by lathe and then quenched, chrome plated and polished, the surface hardness and finish are improved.

4.The cylinder adopts forged parts, the cylinder flange is precisely processed by CNC lathe, with high quality sealing ring, so that the cylinder is not easy to leak oil.

5.The hydraulic system mainly consists of pumps, valve blocks, filling valves, cooling and filtering systems, pipelines, etc. The control of various actions of the hydraulic machine is completed with the help of electrical control system.

6.Designed by three-dimensional modeling and computer finite element analysis, the hydraulic press machineadopts oil heating method, and with the cooperation of proportional valve and synchronous valve, the cylinders are synchronized with high precision and even pressure, which ensures the molding precision of composite aluminum honeycomb panel.

7.The hydraulic press machineis equipped with static and emergency stop buttons, when an abnormality occurs, press the “static” button, all the work of the hydraulic press machinestops; press the “emergency stop” button, including the motor stops running.

| Description | YQ32-500T |

| Nominal pressure | 5000KN |

| System pressure | 25Mpa |

| Slide Stroke | 500mm |

| Opening height | 500mm |

| Working Table size | 3600*1600mm |

| Traveling distance of moving table | 3600mm |

| Motor power | 22KW |

Remark: The above parameters are for reference only, the actual parameters of the machine please refer to the technical program of Shanghai ANTISHICNC.

If you have aluminum honeycomb composite panel processing needs too, welcome to consult Shanghai ANTS Machine Equipment co., ltd. We have rich experience in manufacturing and using hydraulic press machine machine machine and can provide you with professional technical support.