CNC wire EDM processing includes fast wire cutting, medium wire cutting and slow wire cutting, which are widely used in the mold manufacturing industry. So what is the current development status of their technology, processing efficiency, cutting accuracy and surface quality? What are the differences? The engineers of ANTS Machinery Equipment Co., Ltd. will help you answer the questions below.

1. The similarities between fast wire cutting, medium wire cutting and slow wire cutting

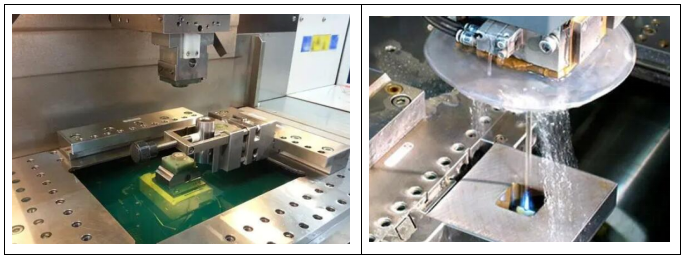

They are all wire-cut electric discharge machines: It is a CNC machining machine tool that can remove metal and complete the task of cutting workpieces. The full English name of the wire EDM machine is Wire-cut Electrical Discharge Machining, and the English abbreviation is WEDM. It can also be said that fast wire-traveling, medium wire-traveling, and slow wire-traveling are all machine tools for metal wire and metal discharge corrosion processing.

2. The differences between fast wire cutting, medium wire cutting and slow wire cutting

First of all, the fast-travel wire-cutting machine is China’s original wire-cut EDM processing model. China is the largest production and usage market. The electrode wire of fast moving wire generally uses molybdenum wire. The medium wire-traveling machine (an upgraded model of fast wire-traveling machine) evolved from fast wire-traveling machine, and its electrode wire also uses molybdenum wire. Compared with the molybdenum wire used in fast-moving wires, the price of medium-moving molybdenum wires is higher. The price of medium wire cutting machine tools is also relatively high. In addition, the fast-moving molybdenum wire can be processed back and forth, which means it can be used repeatedly. In addition, a very important point is that the processing speed of fast wire cutting is fast (high processing efficiency) and the required production cost is relatively low. The processing accuracy of fast wire-traveling machine tools is not as good as that of medium-speed wire-traveling machine tools. The surface roughness of fast wire products is not as good as that of medium wire products, and the surface roughness of medium wire products can reach R0.8um.

What ANTISHICNC(ANTS machine equipment company) engineer said: “The processing speed of medium wire cutting is not slower than that of fast wire cutting machine tools, but is higher than that of fast wire cutting machine tools. It reduces the cutting speed during multiple cutting processes to achieve better cutting effects. . In other words, the calculation of the medium wire-feeding machine tool is not the highest efficiency, but the average cutting efficiency. In addition, the processing quality of the medium-speed wire-feeding machine tool is also close to that of the slow wire-feeding machine tool.”

He also said: “Medium wire cutting machines have the quality of slow wire cutting machines, but only cost the price of fast wire cutting machines!”

The old wire-cutting master also lamented: “The wire cutting machine tool can be said to have brought a revolution to the mold industry.”

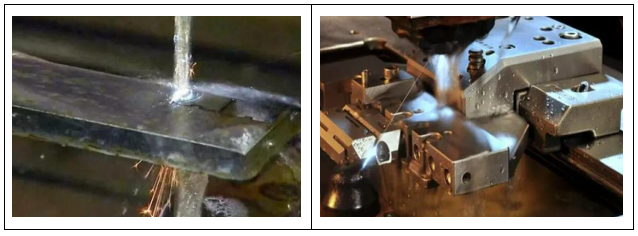

Next, let’s talk about slow-moving wire machines that use electrode wires other than molybdenum wire. The electrode wire of the slow wire machine tool uses copper wire, and the copper wire is disposable. In other words, the slow-moving wire electrode can only be used once. However, the advantage of slow wire cutting is that the processing accuracy is high and can reach within 0.01mm. More importantly, the surface processing roughness of the product is very good, which can reach Ra=0.8μm and above. The disadvantage is that the price of slow wire-moving machine tools is relatively expensive.

3. Industry status and development of fast wire traveling, medium wire traveling and slow wire traveling

3.1 Development status of fast and medium wire processing technology

The biggest advantage of fast wire processing machine tools is that they have a good performance-price ratio. Because of its practicality and economy, it has a large domestic market. Traditional fast wire processing uses a one-time cutting process, the processing efficiency is about 40mm2/min, the surface roughness is about Ra3.0μm, there are obvious lines on the surface, and the processing accuracy is about 0.02mm.

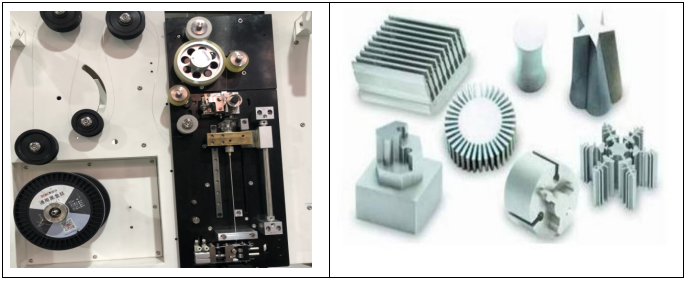

In order to improve the processing quality, manufacturers of fast wire processing machine tools have improved the relevant components of the machine tools by referring to the multiple cutting process, and the so-called “medium wire processing machine tools” have emerged. A large number of process technologies such as machine tools’ CNC accuracy, pulse power supply, wire traveling system, and process database have been greatly improved. The processing accuracy is improved and the surface quality is improved.

The current technical indicators of wire processing machine tools: the efficiency of one cutting is 180mm2/min, the surface roughness after multiple cuts is Ra≤1.0μm, the average efficiency at this time is 50mm2/min, and the processed surface gloss has no obvious cutting streaks , the processing accuracy is 0.01mm, and the electrode wire loss is ≤0. 01 mm /200,000 mm2. These performance indicators seem to be relatively good, but it should be noted that obtaining these indicators requires ensuring all aspects. Once the working conditions change, such as the concentration of the working fluid and the loss of the electrode wire, it will affect the stability of the processing quality. .

According to the author’s understanding, the medium wire cutting machine tool with multiple cutting functions combines the advantages of both fast wire cutting and slow wire cutting machine tools. Logically speaking, it should be the most used in the wire cutting industry and is the “mainstream equipment” in the wire cutting industry. “. But in fact, the author learned from friends in the wire cutting industry that a relatively large proportion of fast wire cutting machine tools are currently used.

Development status of slow wire processing technology

With the continuous improvement of the manufacturing accuracy and surface quality requirements of precision, complex and long-life stamping molds, fast and medium wire processing technology can no longer adapt to the manufacturing requirements of precision molds. This situation has promoted the rapid development of slow wire processing technology. Its process indicators in all aspects have reached a very high level and are irreplaceable by other processing technologies. Therefore, slow wire machine tools are high-end electrical processing equipment and are highly technical. Shanghai ANTS Machinery Equipment Co., Ltd.’s CK400 series of high-speed servo CNC slow wire cutting machine can meet the technical requirements of the high-end mold manufacturing industry. For details, please refer to the following webpage: https://www.antsmachine.com/ac-servo-slow-wire -cutting-machine.html

Summary: There is no perfect technology, only suitable technology. When choosing electrical processing equipment, you need to choose the best one according to the technical requirements of the products produced by your own factory. If you have any technical questions on the selection and selection of electrical machining, mold production, wire cutting equipment, and EDM equipment, you are welcome to consult the ANTS Machine sales team. We will serve you wholeheartedly!

Keywords: fast wire cutting, medium wire cutting, slow wire cutting, mold maufacturing equipment