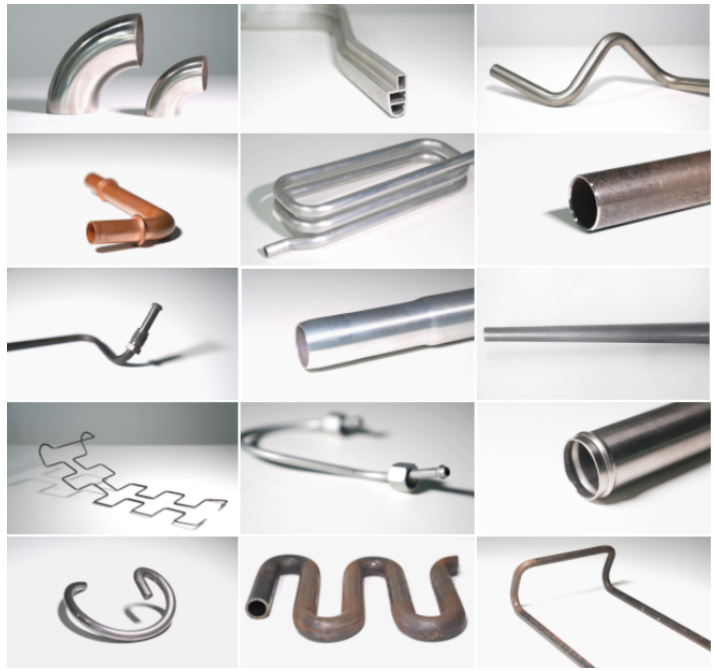

Pipe bending machine in the furniture industry, as well as the processing of office seats, benches, pipe structure beds, etc., all require pipe bending machines to complete the entire set of processing. Especially for bending office chair frames, using a hydraulic pipe bender requires multiple measurements of the length of the bent pipe as well as the size and conversion angle of the feed, and it is difficult to form at one time. When bending this type of pipe, two people need to operate the equipment at the same time. Not only does it require It is labor-intensive and there will be a certain error in the bending angle, resulting in asymmetrical seat angles on both sides or incorrect dimensions at both ends that cannot be connected, etc. Therefore, Shanghai ANTISHICNC engineers recommend using CNC pipe bending machine. Customers can choose and purchase according to the size of the bent seat:

| Specifications | DW18CNC-4A-1S | DW25CNC-3A-1S | DW38CNC-3A-1S | DW50CNC-2A-1S | DW50CNC-6A-3S | DW89CNC-2A-1S | |

| Maximum bending pipe diameter ×Wall thickness | Φ18mm×1.6mm | Φ25mm×1.6mm | Φ38mm×2mm | Φ50mm×3mm | Φ50mm×2mm | Φ89mm×6mm | |

| Carbon steel pipe | Carbon steel pipe | Carbon steel pipe | Carbon steel pipe | Carbon steel pipe | Carbon steel pipe | ||

| Maximum bending radius | R80mm | R180mm | R200mm | R250mm | R250mm | R400mm | |

| Minimum bending radius | R≧1.2D | R≧1.5D | R≧1.5D | R≧1.5D | R≧1.5D | R≧1.5D | |

| Maximum bending Angle | 190° | 190° | 190° | 190° | 190° | 190° | |

| Maximum feeding length | 1800mm | 2200mm | 2200mm | 2200mm | 3200mm | 2700mm | |

| Working speed | Bending speed | Max 200°/s | Max 150°/s | Max 150°/s | Max 85°/s | Max 85°/s | Max 40°/s |

| Tubing speed | Max 200°/s | Max 200°/s | Max 200°/s | Max 200°/s | Max 200°/s | Max 160°/s | |

| Feeding speed | Max 1000mm/s | Max 1000mm/s | Max 1000mm/s | Max 1000mm/s | Max 1000mm/s | Max 800mm/s | |

| Bend way | Servo bending | Servo bending | Servo bending | Hydraulic bending | Servo bending | Hydraulic bending | |

| Corner servo motor | 400w | 400w | 400w | 750w | 750w | 1.5kw | |

| Feed servo motor | 750w | 1000w | 1000w | 1000w | 1000w | 2kw | |

| Left and right mold changing servo motor | 400w | – | – | – | 400w | – | |

| Guide clip servo motor | – | – | – | – | 3000W | – | |

| Bending servo motor | 1500w | 3000w | 5000w | – | 7000w | – | |

| Up and down mold changing servo motor | – | – | – | – | 1500w | – | |

| Pipe fittings allow elbows | 50 | 50 | 50 | 50 | 50 | 50 | |

| Number of parts that can be stored | 500 | 500 | 500 | 500 | 500 | 500 | |

| Oil motor power | 4kw | 4kw | 4kw | 5.5kw | 5.5kw | 11kw | |

| Maximum system pressure | 12 Mpa | 12 Mpa | 12 Mpa | 12 Mpa | 12 Mpa | 12 Mpa | |

| Machine dimensions | 3000 x 700 x 1200mm | 3600 x 900 x 1400mm | 4000 x 900 x 1250mm | 4100x800x1300mm | 5100 x 1400 x 1400mm | 5000 x 1200 x 1500mm | |

| Machine weight | 1400kg | 1200kg | 1300kg | 1300kg | 2400kg | 2800kg | |

The CNC pipe bending machine is very advantageous for bending pipes in the furniture industry, especially pipe bending processing such as seats. The CNC pipe bending machine has a programming function that can perform multi-step bending, and can also realize automatic operation, which can be of great help. Improve the efficiency of producing office seats. Moreover, the CNC pipe bending machine adopts a steel plate welded structure, which can eliminate stress during processing. Moreover, the CNC pipe bending machine uses high-quality imported sealing rings, which are stable, reliable and highly precise. It is the best choice for mass production and processing of office seats. Shanghai ANTISHICNC can provide timely Technical support, training and spare parts supply. We only produce high quality CNC pipe bending machines!

Tags: Pipe Bender,Hydraulic pipe bending machine,CNC pipe bending machine