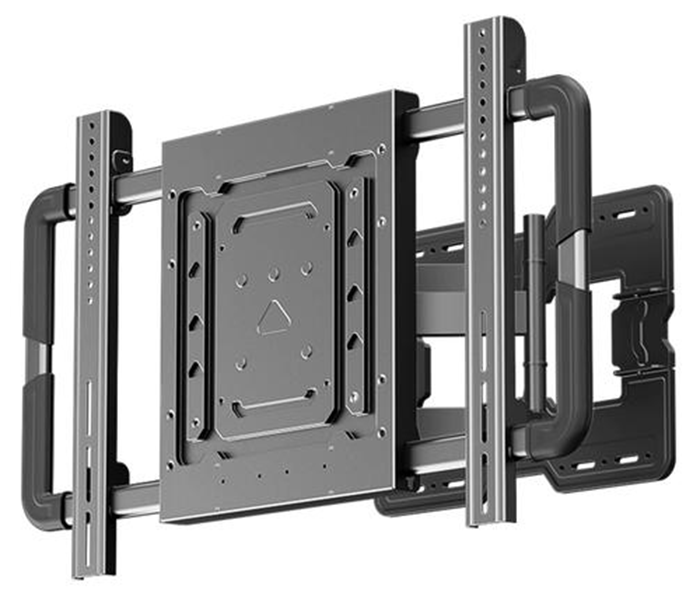

TV bracket parts are the supporting basis of the TV. They can ensure that the TV remains stable in various environments, save space, enhance the overall visual effect, and make the interior decoration more neat and beautiful. The hydraulic press machine is an important machine for making TV bracket parts. So what are the advantages of using a hydraulic press machine to make TV bracket parts?

1.High precision and consistency

① Uniform pressure distribution: The hydraulic press machine transmits pressure through liquid to ensure uniform force on the mold, reduce deformation of parts, improve dimensional accuracy, and is suitable for the high-precision requirements of TV brackets for mounting interfaces.

② Batch stability: Suitable for mass production, ensuring high consistency of accessory dimensions, and reducing adjustment costs during assembly.

2.Complex structures are formed in one go

① Flexible mold design: Complex geometric structures (such as curved surfaces, hollowing, and reinforcement ribs) can be formed to enhance the load-bearing capacity and aesthetics of the bracket and reduce the need for multi-process processing.

② Material flow control: High-pressure liquid allows the material to fully fill the mold, avoiding cracking or wrinkles that may occur in traditional stamping.

3.High material utilization

① Reduced waste: By optimizing the mold design, “near-net molding” is achieved, scraps are reduced, costs are saved, and environmental protection trends are met.

② Applicable to a variety of materials: Compatible with metals (such as aluminum alloys, steel) and engineering plastics to meet different load-bearing and lightweight requirements.

4.Production efficiency and automation

① High-speed continuous production: hydraulic press machine can integrate automated feeding and picking systems, shorten cycle time, and are suitable for large-scale orders.

② Low mold cost: Compared with stamping, hydraulic forming molds are simpler and more durable, with low maintenance costs, and are especially suitable for small and medium-sized batch flexible production.

5.Superior product performance

① High-strength structure: High-pressure forming makes the internal grains of the material denser, improving the mechanical strength and fatigue resistance of the bracket.

② High surface quality: The surface is smooth after forming, reducing subsequent grinding, spraying, and other processes, and shortening the production cycle.

6.Energy saving and environmental protection

① Energy consumption optimization: Compared with traditional mechanical presses, the hydraulic system consumes less energy in the pressure holding stage, and can further save energy through frequency conversion technology.

② Green manufacturing: The characteristics of low noise and low waste meet the requirements of sustainable development.

7.Application flexibility

① Adjustable parameters: By adjusting the pressure and speed to adapt to the production of accessories of different thicknesses or materials, quickly switch product models.

② Adapt to diversified designs: It is easy to iterate and upgrade the bracket structure (such as adjustable angles and hidden cable designs) to meet the differentiated needs of the market.

These advantages make the press-fit hydraulic press machine play an important role in the production of TV bracket parts, which not only improves production efficiency and product quality, but also reduces production costs and enhances the market competitiveness of enterprises.

Shanghai ANTS Machine Equipment Company is a manufacturer specializing in the production of hydraulic press machine. The hydraulic press machine for TV bracket parts produced by Shanghai Antis adopt an all-steel plate welding structure, advanced hydraulic transmission technology, and control system, with high rigidity and high precision, and are well received by customers. For example, the following 315-ton three-beam four-column hydraulic press machine.

Features of 315 ton three-beam four-column hydraulic press machine:

1.Computer-optimized structural design, three-beam four-column structure, simple, economical, and practical.

2.The hydraulic control adopts a cartridge valve integrated system, which has reliable action, long service life,and small hydraulic shock, and reduces the connection pipeline and leakage points.

3.Independent electrical control system, reliable operation, intuitive action, and convenient maintenance.

4.Adopting button centralized control with two operation modes of adjustment and semi-automatic.

5.Through the selection of the operation panel, two forming processes of fixed stroke and fixed pressure can be realized, and it has functions such as pressure holding and delay.

6.The working pressure of the slider and the travel range of no-load fast downward and slow working can be adjusted according to the process needs.

| Description | Unit | YQ32-315T | |

| Nominal force | KN | 3150 | |

| Maximum liquid pressure | Mpa | 25 | |

| Slider stroke | mm | 500 | |

| Maximum opening height | mm | 900 | |

| Ejection force | T | 63 | |

| Working table size | Left and right | mm | 1260 |

| Front and back | mm | 1160 | |

| Slider speed | downlink speed | mm/s | 100 |

| Work | mm/s | 6-15 | |

| Return | mm/s | 80 | |

| Motor power | kw | 22 | |

Remark: The above parameters are for reference only, the actual parameters of the machine please refer to the technical program of Shanghai ANTISHICNC.

If you have TV bracket parts forming processing needs too, welcome to consult Shanghai ANTS Machine Equipment co., ltd. We have rich experience in manufacturing and using hydraulic press machine machine and can provide you with professional technical support.