Pipe bending machine is a common metal processing equipment, its main purpose is to bend metal pipes into pipes of different shapes. Pipe bending machines have the characteristics of simple operation, high work efficiency, high precision, and wide application range. Therefore, they are widely used in many fields, such as: construction field, energy field, automobile industry, shipbuilding industry, etc.

So how to choose a suitable pipe bender? The following is the key selection parameters from the bender and the type of bender and the need to bend the type of material to introduce you to two aspects.

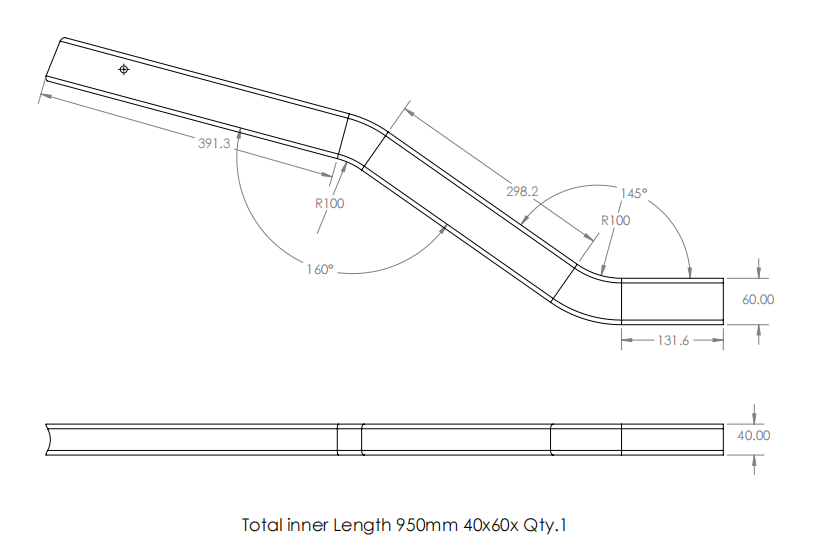

1. Key parameters for pipe bending machine selection

D: pipe outer diameter

T: pipe wall thickness

R: bending radius

Material

(If you can provide workpiece drawings, we can quickly help you select the model)

The outer diameter D of the pipe fitting only reflects the size of the pipe fitting. The ease of bending the pipe fitting depends on the wall thickness T and bending radius R of the pipe fitting. The smaller the wall thickness T of the pipe fitting, the smaller the radius R, the greater the difficulty in processing.

With these 4 parameters, the preliminary selection of the pipe bending machine can be completed. For workpieces with complex drawings and multiple R’s, we recommend using a CNC machine, which can be molded in one go without changing molds. This helps reduce labor costs and improve production efficiency. When choosing CNC machine models, we also need to give specific opinions based on specific drawings.

2.Introduction to machine models of Shanghai ANTS Machine.

There are mainly 2 series of pipe bending machines in Shanghai ANTS Machine

1. Ordinary series: DW38NC, 50, 63, 75, 89, 100, 114, 130, 168

The structural form of this series of machines is basically the same, hydraulic transmission, microcomputer controller control, and digital angle control device. This series of pipe bending machines has comprehensive functions. It can bend difficult pipe fittings such as stainless steel thin-walled pipes and small bending radius pipes when equipped with some mold options such as anti-wrinkle blocks, active cores, etc. This series of pipe bending machines are widely used in automobiles and motorcycles, furniture, fitness equipment, decoration, air conditioners, boilers, shipbuilding, electric power, chemical pipelines and other industries.

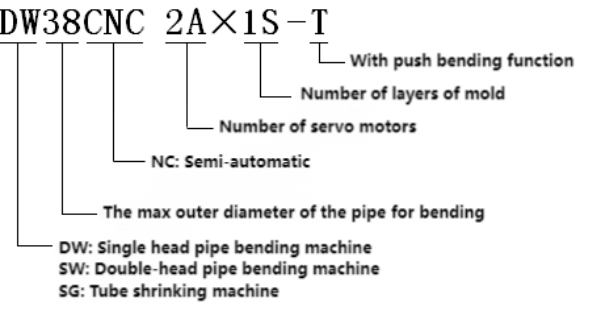

2. CNC series: DW38CNC, 50, 63, 75, 89, 100, 114, 130, 168

The CNC pipe bending machine is characterized by its practicality. It uses a PLC+axis control module to control the two motor axes and an electro-hydraulic proportional control arm axis. The main electrical and hydraulic components are all imported components. The graphical operation interface in Chinese and English is very convenient to operate. People who have used pipe bending machines can generally learn it in one day. Since PLC is used as the main control system, the requirements for maintenance personnel are not very high, and both junior and intermediate technicians can be competent. Its main users are automobile muffler factories, motorcycle frame manufacturing factories, shipyards, etc.

3. Types of bending materials

Steel profiles: round tubes, square tubes, channel steel, angle steel, I-beam, flat steel, etc.

Stainless steel: square tubes, round tubes, profiles, oval tubes and special-shaped tubes, etc.

Copper materials: square tubes, round tubes, profiles, oval tubes and special-shaped tubes, etc.

Aluminum profiles: various special-shaped materials for building decoration and balcony railings, handrails, etc.