Compared with manual loading and unloading, CNC machine tool loading and unloading robots have the advantages of high overall efficiency, low labor costs, stable product quality (no emotional impact on workers), low labor risks and fewer labor disputes. Under the trend of “machine substitution”, more and more enterprises have introduced loading and unloading robots for machining production. There are several ways of CNC automatic feeding.

1. Vibrating plate feeding: use the vibration of the vibrating plate to automatically sort the materials: vibrating to meet the needs of the next step, such as automatic retrieving or automatic feeding; the vibrating plate can screen products: the vibrating plate can not only automatically sort Products can be sorted, and some simple products can also be filtered, such as screws of different specifications. However, it is difficult to meet the relatively high requirements through the vibrating plate.

2. Lifter feeding machine feeding: Use chain plate and conveyor belt to lift the parts to be processed from the material basket and transfer them to the machine feeding port. This feeding method is efficient, fast and low in cost. It has a wide range of applications and can be used for CNC Lathes transfer materials in a wide range of sizes.

3. Oil bath automatic feeder

The motor drives the oil pump, and the oil pump pumps oil to supply oil to the outer pipe of the feeder, and the hydraulic oil pushes the piston rod (push rod) to push the material into the main shaft. Under the action of centrifugal force during work, when the rotation speed is fast, the bar will automatically rotate in the center of the material tube. Effectively reduce the collision and friction between the bar and the feeding pipe wall. The vibration and noise are very small when working, especially suitable for copper bar, aluminum bar and precision workpiece processing. The oil bath feeder can be used with various lathes, and cooperate with the machine tool to complete the automatic feeding work. After the bar is automatically fed, the machine tool is automatically in the state of waiting for feeding, and the operator is notified to feed through the warning device. Maximum feeding length: ≤2.5 meters, feeder length: 3800mm. Applicable bar diameter 3-45mm

4. Oil film automatic bar feeder and short bar feeder

Oil film type automatic bar feeder High speed, no noise. Multiple parameter settings, abnormal detection, function display, driven by AC servo motor. It adopts PLC control circuit, which has high stability and simple operation. It adopts high steel structure, and the frame is stable and durable. Electronic synchronous device, suitable for center-type CNC lathe, fast speed and high stability. Quick-release PU pull tube, quick and easy to replace, more effective in suppressing vibration, and exerting the best performance; short rod feeder can transport non-ferrous metal materials “Black leather” material, suitable for automatic feeding of CNC lathes;

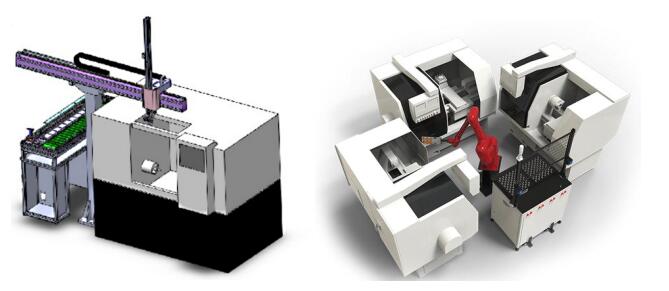

5. The truss loading and unloading manipulator automatically grabs and loads the material

This kind of truss loading and unloading manipulator is controlled by PLC. The loading and unloading machine of the manipulator and the fixture can be universally designed according to the requirements of users. The material machine adopts the design elements of easy-to-change workpiece models to realize the compatibility of various workpieces. It not only meets the requirements of “small It is also applicable to the application requirements of “multiple varieties and small batches”.

6. Intelligent robot manipulator loading method: The loading and unloading robot can be controlled without relying on the controller of the machine tool. The manipulator adopts an independent control module, which does not affect the operation of the machine tool. It can realize automatic loading/unloading, workpiece turning, and workpiece reordering for workpieces such as discs, long shafts, irregular shapes, and metal plates; it has good rigidity, stable operation, and is very convenient for maintenance. Optional: independent silo design, independent automatic control of silo. It is controlled by independent assembly line and other methods; it is an ideal high-efficiency equipment for joint operation of CNC lathes and automatic production of multi-station and multi-process.

Shanghai ANTS Machinery Equipment Co., Ltd. can follow up the size drawings of customers’ workpieces for customized production and provide their own automation solutions. Welcome to contact our sales staff. Email: contact@antsmahcine.com

Tags: CNC lathe automation, loading and unloading manipulator, automation, robot