|

|

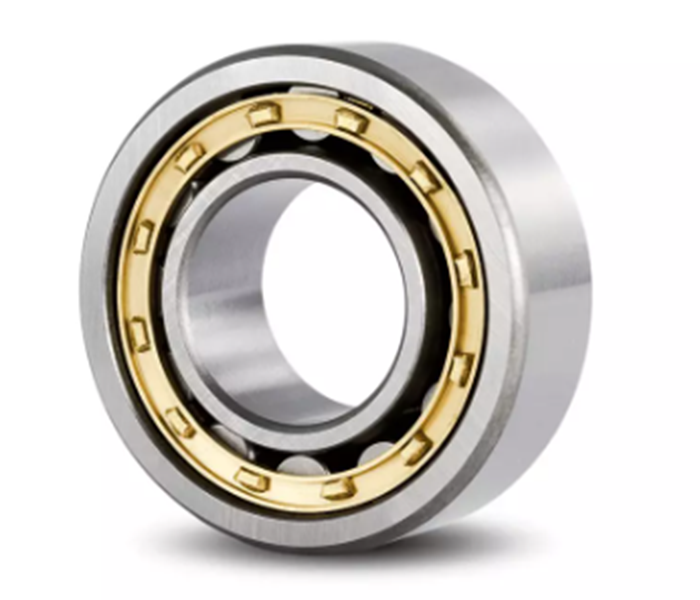

CNC lathes have high processing accuracy, with non-circular curve interpolation processing functions, and the ability to automatically change speed during processing. Therefore, according to the characteristics of CNC lathes, the inner and outer rings of bearings are suitable for CNC turning.

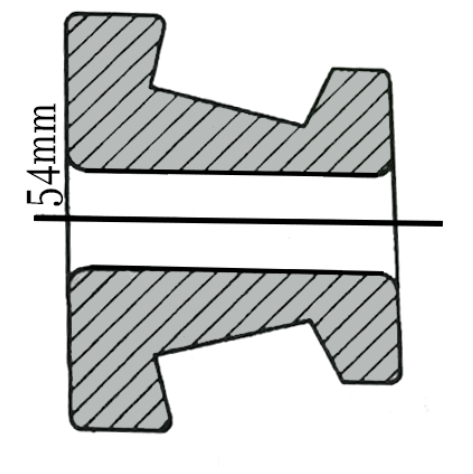

The inner ring of the bearing is a rotating part with high precision requirements. Due to the good rigidity of CNC lathes, high manufacturing and tool setting accuracy, and convenient and accurate manual compensation and automatic compensation, it can process parts with high dimensional accuracy requirements. In addition, the tool movement of CNC turning is achieved through high-precision interpolation calculations and servo drives. Coupled with the good rigidity and high manufacturing accuracy of the machine tool, it can process parts with high shape accuracy requirements such as generatrix straightness, roundness, and cylindricity. For circular arc and other curved contours, the degree of closeness of the processed shape to the geometric shape required on the drawing is much higher than that of a copy lathe. The inner ring of the bearing shown in the figure below:

| Machining accuracy of inner and outer rings of bearings (unit: mm) | |||

| Inner Bearing Rings | Outer Bearing Rings | ||

| Items | Standard | Items | Standard |

| Diameter size repeatability error | <0.02 | Diameter size repeatability error | <0.02 |

| Wall thickness difference | <0.02 | Wall thickness difference | <0.02 |

| Roundness error | <0.02 | Roundness error | <0.02 |

| Dustproof groove height repeatability error | <±0.02 | Dustproof groove height repeatability error | <±0.02 |

| Roughness | ≤1.6 | Roughness | ≤1.6 |

|

If hydraulic semi-automatic lathes and hydraulic copy lathes are used for processing, multiple clamping is required, which will cause a large wall thickness difference and fail to meet the requirements of the drawings. If CNC inclined lathes are used for processing, the turning of the raceway and inner hole can be completed in one clamping, the wall thickness difference is greatly reduced, and the processing quality is stable.

|

|

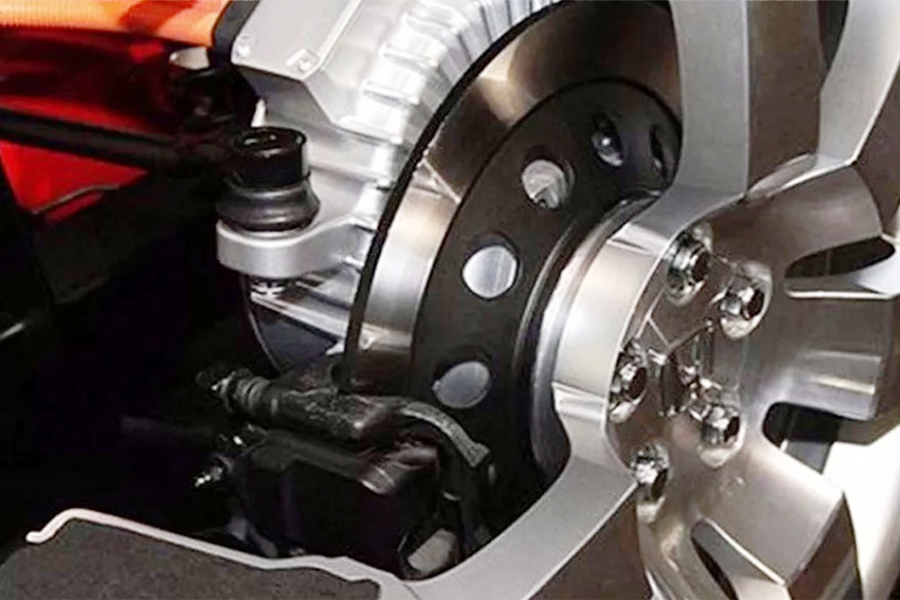

Shanghai ANTISHICNC engineer recommend using TCK36A CNC slant lathe for bearing processing

TCK36A uses HIWIN high-precision ground ball screws, combined with HIWIN high-precision ball linear guides, high efficiency and reversibility, zero backlash and high rigidity, high lead precision, predictable life, low starting torque and smoothness, silent and short delivery period, which are superior to gas-hydraulic actuators.

Keywords: CNC lathe, CNC slant bed lathe, precision CNC lathe, Bear CNC lathe