Wire EDM belongs to the category of electrical machining. Its physical principle is: free positive ions and electrons accumulate in the field, and soon form an ionized conductive channel. At this stage, a current is formed between the two plates. This leads to numerous collisions between the particles, forming a plasma zone, which quickly rises to a high temperature of 8,000 to 12,000 degrees, instantly melting some materials on the surfaces of the two conductors, and at the same time, due to the vaporization of the electrodes and the dielectric liquid, a bubble is formed, And its pressure rules go up until very high.Then the current is interrupted, and the temperature suddenly drops, causing the bubbles to explode inward, and the generated power throws the melted material out of the crater, and then the corroded material re-condenses into small spheres in the dielectric liquid, which is expelled by the dielectric liquid. Then through the monitoring and control of NC control, the servo mechanism executes to make this discharge phenomenon uniform.

According to the wire speed, WEDM can be divided into Reciprocating type High Speed Wire cut Electrical Discharge Machining, commonly known as “fast wire”; Low Speed one-way walk Wire cut Electrical Discharge Machining, commonly known as “slow wire” and Vertical Wire Electrical Discharge Machining machine tool With Rotation Wire. It can also be divided into single-column cross workbench type and double-column type (commonly known as gantry type) according to the workbench form.

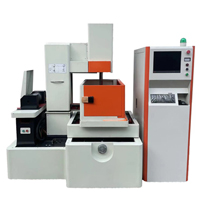

1. Reciprocating wire EDM wire cutting machine (fast wire)

The wire speed of the reciprocating wire EDM wire cutting machine is 6-12 mm/s, which is a unique machine in my country. Since September 1970, the “Digital Program Automatic Control Wire Cutting Machine Tool” has been successfully developed by the state-owned ChangFeng Machinery General Factory under the Third Ministry of Machinery Industry, which is the first of its kind in China. With the gradual improvement of the large-taper cutting technology, great progress has been made in the cutting process of variable taper and upper and lower special shapes. The breakthrough of large thickness cutting technology has greatly improved the accuracy of cross section and longitudinal section, and the processing thickness can exceed 1000mm. The reciprocating wire cutting machine has certain advantages. It is used in all kinds of medium and low-grade mold manufacturing and special parts processing, and has become one of the most widely used types of CNC machine tools in my country. However, since the reciprocating wire cutting machine cannot implement constant tension control on the electrode wire, the electrode wire vibrates greatly and the wire is easily broken during processing. Since the electric grade wire is used in a reciprocating manner, the electrode wire will be lost, and the machining accuracy and surface quality will be reduced.

2. Low-speed one-way wire EDM wire cutting machine (slow wire)

The electrode wire of the low-speed wire cutting machine uses copper wire as the tool electrode. Generally, it moves in one direction at a speed lower than 0.2mm/s, and applies 60~60~ 300V pulse voltage, and maintain a gap of 5~50um, the gap is filled with insulating media such as deionized water (close to distilled water), so that spark discharge occurs between the electrode and the workpiece, and each other is consumed and corroded, and the surface of the workpiece is electrified. Numerous small pits are etched out, monitored and controlled by NC and executed by servo mechanism, so that the discharge phenomenon is uniform and consistent, so that the processed object can be processed, making it a product with the required size and shape accuracy. The accuracy can reach 0.001mm level, and the surface quality is also close to the grinding level. The electrode wire is no longer used after discharge, and uses a non-resistance anti-electrolysis power supply, generally with automatic wire threading and constant tension devices. The work is stable, uniform, with small jitter, high machining accuracy and good surface quality, but it is not suitable for processing large thickness workpieces. Due to the precise structure of the machine tool, the high technical content, and the high price of the machine tool, the cost of use is also high.

3. Vertical self-rotating wire EDM

Vertical self-rotating wire EDM (horizontal self-rotating wire EDM). The characteristics of the vertical rotary wire EDM are different from those of the traditional high-speed and low-speed wire EDM. First of all, the movement mode of the electrode wire has one more electrode than the traditional two kinds of EDM. The rotary motion of the wire; secondly, the wire speed of the electrode wire is between the high-speed wire and the low-speed wire, and the speed is 1 ~ 2mm/s. Due to the increased rotational movement of the electrode wire during the processing, the biggest difference between the vertical rotary EDM wire cutting machine and other types of wire cutting machines is the wire feeding system. The wire feeding system of the vertical rotary wire EDM consists of two ends with the same structure as the wire feeding end and the wire feeding end as the wire feeding structure, which realizes the high-speed rotating motion of the electrode wire and the composite motion of the low-speed wire feeding. The area between the two sets of spindle heads is the effective machining area. Except for the wire cutting system, other components of the machine tool are the same as the high-speed wire cutting machine.

Compared with unidirectional low-speed wire EDM machine tools, there is still a big gap in key technical indicators such as average productivity, cutting accuracy and surface roughness of reciprocating high-speed wire EDM machine tools. In response to these gaps, at the beginning of this century, there were several domestic high-speed reciprocating wire EDM manufacturers, including Shanghai ANTS, which realized multiple cutting processes on high-speed wire-feeding machines (this type of machine tool is commonly known as “the middle-speed wire cutting machine”). The so-called “medium wire travel” does not mean that the wire travel speed is between high speed and low speed, but a composite wire cutting machine tool. 1-3mm/s low-speed wire feeding is adopted during processing, so that the work is relatively stable and the jitter is small, and the error caused by material deformation and molybdenum wire loss is reduced by multiple cutting, so that the processing quality is relatively improved, and the processing quality can be between high-speed Between the wire feeder and the low-speed wire feeder.

Multiple cutting is a comprehensive technology, which involves the CNC precision of the machine tool, pulse power supply, process database, wire feeding system, working fluid and a large number of process problems. It is not simply adding a set of high-speed wire feeding machines. Only those reciprocating wire EDM machines that have high manufacturing precision and create multiple cutting conditions in various aspects can perform multiple cutting and streak-free cutting, and obtain remarkable results. Process effect. Therefore, Shanghai ANTS fully pays attention to this problem, insists on doing it according to system engineering, really makes good use of this technology, and makes this product well. The AC servo motor is used as the drive unit to directly drive the ball screw. At the same time, the full closed-loop control with the pitch compensation function is adopted, and the CNC system can be used to compensate and correct the positioning accuracy error of the machine tool. On the premise of ensuring accuracy, the reduction of machining accuracy caused by long-term use is reduced, and the service life of the machine tool is extended. The wire transport system adopts a special (mostly diamond) electrode wire holder to keep the electrode wire relatively stable and reduce the tension change of the electrode wire during processing. In terms of cooling system, the commonly used rough cooling method is changed, multi-stage filtration is adopted, and key parameters such as dielectric constant are controlled to ensure the smooth progress of finishing. The control software provides an open processing parameter database, and the corresponding processing parameters can be selected according to the texture, thickness, roughness and other conditions of the material. It is believed that through our efforts, the multiple cutting technology will be more perfect, and the reciprocating wire EDM processing technology will also be better applied and developed.

Wire EDM classification: fast wire cutting, medium wire cutting, slow wire cutting.

1: The wire speed of fast wire EDM wire cutting is 6 to 12 mm/s, and the electrode wire moves back and forth at high speed, and the cutting accuracy is poor. 2: The medium-travel wire EDM is based on the fast-travel wire cutting to realize the variable frequency multiple cutting function.

3: The wire speed of slow wire EDM wire cutting is 0.2mm/s, and the electrode wire moves in one direction at a low speed, and the cutting precision is very high.

As a leading manufacturer of industrial lathe machinery and machine tools in China, Shanghai ANTS has 20 years of experience in machine tool production. The lathe machinery and other equipment it produces are not only used in the automotive industry, construction industry, but also in the mold industry.

If you have any questions or needs, please contact the Shanghai ANTS sales team! ! !

http://www.antsmachine.com

Email : Contact@antsmachine.com