Tool grinder filter is a filter designed specifically for tool grinders. Its main function is to filter the coolant containing metal chips, grinding wheel particles and oil pollution generated by the tool grinder during the processing process to ensure the cleanliness of the coolant, so that it can be recycled and also help to extend the service life of the tool grinder. A suitable filter is indispensable for tool grinders.

The differences between tool grinder filters and ordinary grinder filters are:

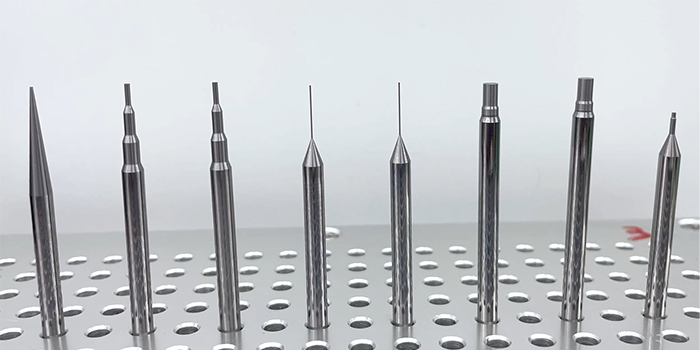

1.Higher precision requirements: Tool grinders are used to process various precision tools, such as knives, drills, etc. These tools have extremely high requirements for dimensional accuracy and surface quality. Therefore, tool grinder filters need to have higher filtration accuracy and be able to remove tiny impurities. Generally, they can achieve a filtration accuracy of 1-10 microns, while ordinary grinder filters may have an accuracy of about 10-30 microns.

2.Stronger adaptability: There are various types of tool grinders, including tool grinders, drill grinders, etc., and the types and characteristics of coolants used are also different. Special filters can better adapt to the coolant systems of different types of tool grinders.

3.More accurate flow adaptation: The coolant flow of tool grinders is usually adjusted according to the processing accuracy and method of the tool. Special filters can accurately match the coolant flow requirements of specific tool grinders to ensure that the coolant can be filtered and circulated in a timely and effective manner during the processing, while ordinary grinder filters may be relatively rough in flow matching.

So how to choose the right filter for the customer based on the customer’s tool grinder?

1.Need to know the information of the customer’s tool grinder: the size of the grinder, the number of grinders that need to be connected to the filter

2.The material of the workpiece processed by the customer’s tool grinder

3.The customer’s requirements for the placement of the grinder, from which the pipeline requirements can be confirmed

This week, Shanghai ANTISHICNC received an inquiry from a Slovenian customer who needed a filter for his high-precision step grinder. After communicating with the customer, it was confirmed that the customer had three grinders, so we recommended our X-300 model high-precision grinding fluid filter to the customer.

| Specifications | X-300 |

| Filtration system capacity | Continuous filtration capacity of at least 450 litres per minute |

| Filtration accuracy | 1µm |

| Filtration medium | Reusable waterproof filter element |

| Filtration requirements | Impurities are hard alloy tungsten steel ash powder and grinding wheel ash |

| Compressed air requirements | Dry compressed air greater than 6bar, flow greater than 20CFM, interface greater than Φ12mm |

| Power supply requirements | 50HZ , 380V(Can be customized) |

| Minimum fuel requirements | ≥1600L (reference value, actual demand needs to be determined based on pipeline and distance) |

| Backwash method | Automatic backwash |

| Liquid supply interface size | DN50 |

| Liquid return port size | DN150 flange |

| Rated power | 9kw (without refrigeration) |

| Filter housing dimensions | 2500*1700*2000mm |

| Filter housing thickness | 3mm |

| Oil tank floor thickness | 5mm |

This filter is suitable for customers’ workpieces, made of tungsten carbide, and can meet the filtering needs of three devices at the same time. It is cost-effective and practical for customers!

|

|

If you have similar needs, please contact Shanghai ANTISHICNC: contact@antsmachine.com, we will definitely provide you with the most suitable solution for you to choose.

Keywords: Tool grinder, Step grinder, Grinder