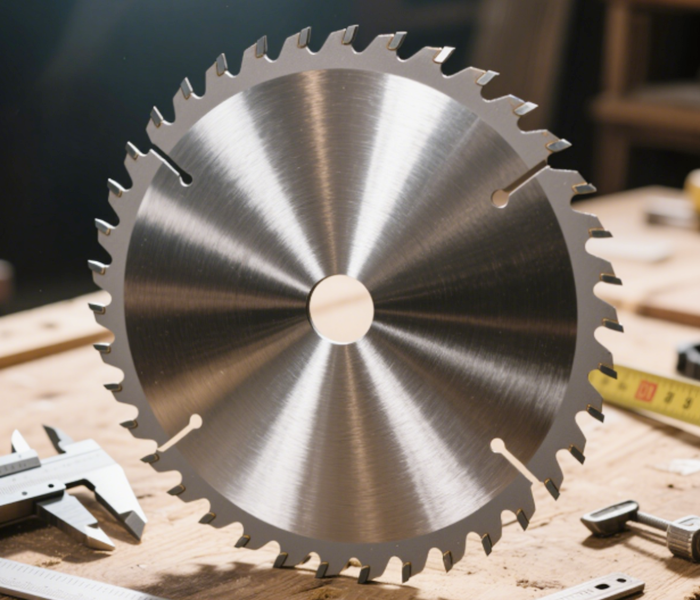

When processing materials such as metal or plastic, circular saw blades are key cutting tools. Whether they are properly selected directly affects processing efficiency, finished product quality, and tool life. Many people often don’t know where to start when faced with a wide variety of circular saw blades. In fact, as long as you master a few key points, you can easily choose the most suitable saw blade.

Here are 5 key points for choosing saw blades:

1.Saw blades are divided into different outer diameters/inner holes and uses. The tooth angles and steel plate forms they are designed with are different. Please choose according to the objects you want to process and cut.

2.The speed of the equipment is one of the key factors. It is better to match the spindle speed and feed speed according to the different cutting objects. Sometimes the equipment level is not enough (such as the speed is too slow and does not meet the speed requirements of the cutting object). Even if the best saw blade in the industry is used, it cannot play its due performance 100%. It is like installing a BMW engine in a small MARCH. The peripheral equipment cannot be matched. It is a futile effort. The only economical and smart way is to use the right saw blade for the right material.

3.Tooth number selection: Many customers will tell us that they want a saw blade with 100 or 120 teeth. However, after understanding the cutting conditions, they find that the material is a bit thick and is not suitable for cutting with so many teeth. At this time, the customer will ask: But wouldn’t more teeth make the cut more beautiful?

A: Well, basically it is like this. The multi-tooth saw can cut beautifully, but after long-term mechanical operation, because the tooth pitch is too dense, there is not much space for chip removal between each tooth, which can easily increase the friction between the tooth edge and the workpiece, thus affecting the service life of the blade, especially for plastic workpieces. It is easy to generate heat during high-speed cutting, and the plastic will melt and stick between the teeth. After the tooth edge enters moderate wear, it will slowly lose its sharpness. If it continues to be used, it will enter the intensive wear period. In the absence of space for heat dissipation and chip removal, the blade has lost its sharpness. If it is still not immediately removed for grinding and maintenance, the saw blade is not cutting , but cutting by hard squeezing. Or there are impurities or collisions with high hardness in the workpiece, which will cause the saw teeth to break. In more serious cases, even the tooth steel seat is broken.

The following is a table of recommended numbers of teeth:

| Material thickness | Reference number of teeth |

| 1-5mm | 120 teeth |

| 6-10mm | 100 |

| 10-15mm | 80-90 |

| 15-20mm | 60-80 |

| 20mm or more | 60 |

| 30-50mm | According to the saw blade size/speed, 30 or 40 teeth are available |

4.Professional grinding: Therefore, saw blades that have become blunt, produce strange sounds, have an unsightly cut surface, are heavily cut, and are about to enter the period of intensive wear should be removed regularly and handed over to a professional grinding factory for re-grinding and repair at the original angle.

5.Saw blade steel plate and tungsten steel cutter head tooth quality: The 5th point is the most important point. Saw blade steel plate seems easy, but it does have a lot of knowledge. Whether it has undergone precise laser cutting, heat treatment without cutting corners, and steel plates without cutting materials are all key points. When the saw blade is cutting quickly, the heat generated by the tungsten steel cutter head will be transferred to the saw plate, causing the temperature of the saw plate to rise (at this time, an appropriate amount of cutting coolant must be sprayed to cool it down according to needs). High-quality saw plates can still maintain excellent accuracy at this time. On the contrary, poor quality saw plates are prone to “reverse board warping”. At the same time, “reverse board” will also occur when the tooth edge is too blunt, but it is still barely used, or when cutting inappropriate workpieces or heavy cutting, which will also cause the saw plate to “reverse board warping”.

In summary, choosing a suitable circular saw blade requires comprehensive consideration of factors such as outer diameter and inner hole specifications, equipment speed, number of teeth matching, professional grinding and maintenance, and steel plate and cutter head quality. Only by integrating these key points, accurately selecting according to specific processing needs, and doing a good job of daily maintenance, can the circular saw blade always maintain its best performance, improve processing efficiency, ensure processing quality, and maximize economic benefits.

Learn more about circular saw blades or need to match the right circular saw machine or saw blade

Please visit: www.antsmachine.com

Or send an email to contact@antsmachine.com

Our engineers will work with you to find the most appropriate solution for you.

Keywords: Saw blade, Circular saw blade , Circular saw machine