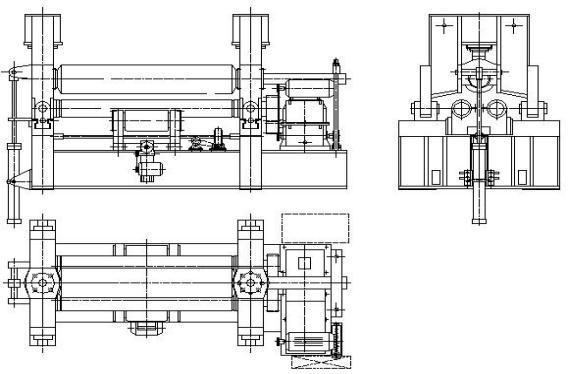

As the core equipment for bending and forming metal plates, the upper roller universal plate rolling machine has an ingenious structural design. It takes the upper roller as the core and cooperates with the flexibly adjustable lower roller. Through hydraulic or mechanical drive and combined with a high-precision control system, it can accurately adjust the roller position, pressure and rotation speed according to the different materials, thickness and curvature requirements of the plate. This equipment not only supports the rolling of various cross-sections such as round, arc, and cone, and is suitable for a variety of materials such as low-carbon steel and stainless steel, but also is equipped with a CNC system and safety protection devices to achieve parameter preset, automatic operation and safety assurance.

With its excellent performance, the upper roller universal plate rolling machine plays an important role in many fields. In industrial manufacturing, it can be used for rolling components such as pressure vessel cylinders and fan casings; in the field of engineering construction, it can meet the processing needs of large-diameter pipelines and steel structure brackets; in the shipbuilding and aerospace industries, it is also competent for the complex curved surface forming of hull shells and aircraft arc-shaped parts. Its efficient and precise forming capabilities make it an indispensable and important equipment in industrial manufacturing.

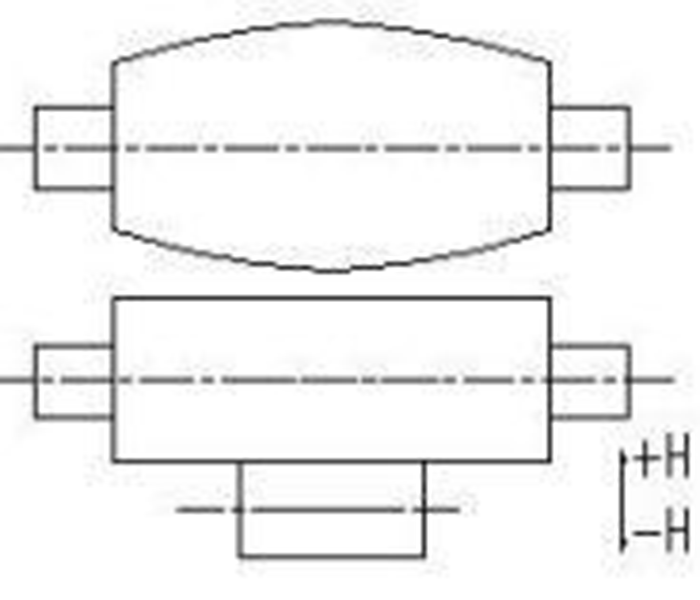

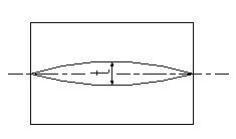

1.The upper roller with drum shape and the lower roller with lower roller are adjusted to improve the straightness of the high-precision products

The upper roller with drum shape is generally preset to 70% of the uniform load of the roller; the lower roller with smaller diameter has an upper and lower adjustable roller support. According to the load of the rolled product, the roller under the lower roller is adjusted to greatly improve the straightness of the product.

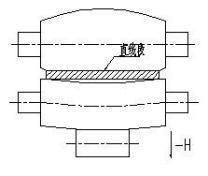

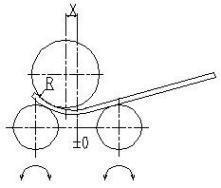

A.Rolling thick plates

When rolling thick plates, the roller at the bottom of the lower roller is adjusted upward; the product shape “purse mouth” t value is very small, and the product straightness is high.

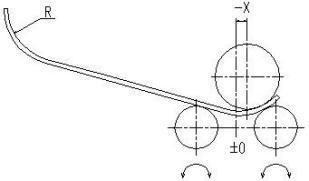

B.Thin plate rolling

When rolling thin plates, the roller under the lower roller is adjusted downward; the product shape cannot appear “waisted”, and the product has high straightness.

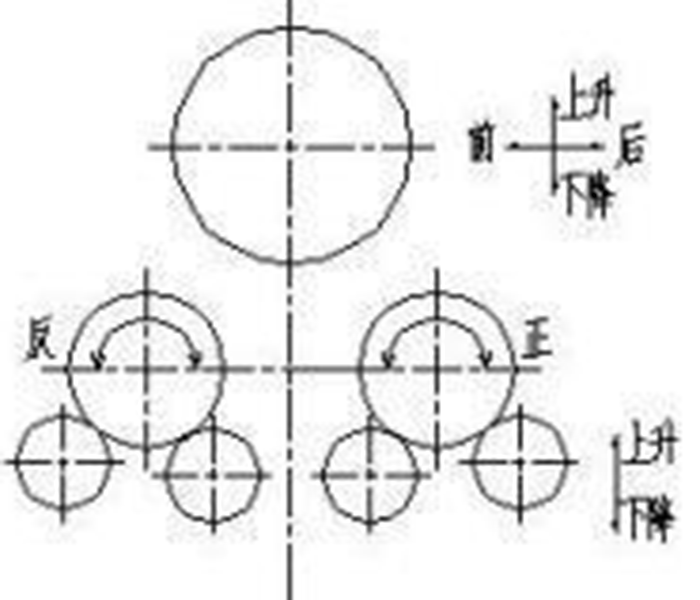

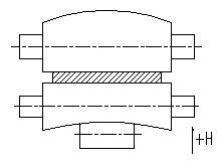

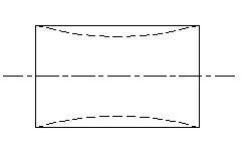

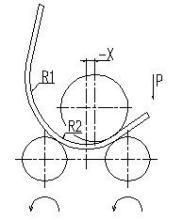

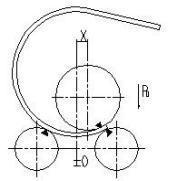

2.Rear bending and rolling to improve the roundness of high-precision products

The upper roller universal plate rolling machine adopts rear bending (the direction of plate feeding is opposite to the direction of upper roller movement). The upper roller presses down while the lower roller rotates, and the plate is bent continuously. The end of the plate is pre-bent directly by pressurization, which avoids the generation of the front bending back angle, and can control the length and shape of the remaining straight edge.

Generally, the three-roller asymmetric type adopts front bending, first pre-bending the two ends of the plate, and then symmetrically rolling to form, which requires skilled operators, the product has a back angle, and the shape of the remaining straight edge is difficult to control.

| Type | A.Universal upper roller plate rolling machine | B. Three-roller asymmetric type (upper roller horizontal adjustment type, lower roller horizontal adjustment type, arc downward adjustment type, four-roller plate bending machine, etc.) |

| Pre-bending method |  |

|

| The upper roller presses down while the lower roller rotates | Pre-bend the ends of the sheet first, then roll symmetrically | |

|

|

|

| The ends of the plates are pre-bent by direct pressure | The lower roller rotates forward and reverse, pre-bending first and then rolling | |

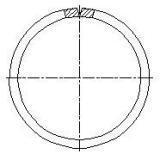

| Product shape |  |

|

| The product has no back angle, the end of the remaining straight edge is controlled on the standard circle, and the roundness of the product is high. | The product has a back angle, and it is difficult to control the end of the remaining straight edge to be on the standard circle, so the roundness of the product is not high. |

If you need to buy a plate rolling machine, or have any questions about plate rolling machine equipment, please consult ANTISHICNC, we will provide you with professional advice! Please contact contact@antsmachine.com