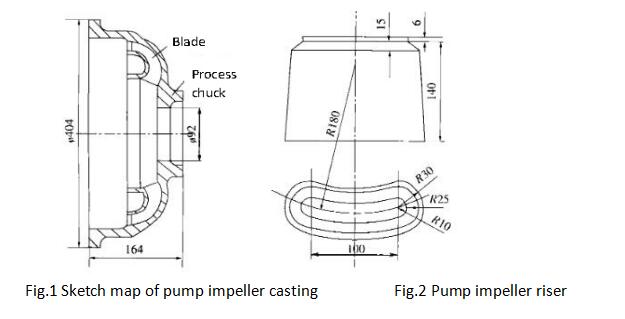

The pump wheel, one of the four elements of the torque converter in the loader, is a wheel-shaped casting with blades, made of ZL104 aluminum alloy. The maximum outline size of the casting is 404mmx64mm, the maximum wall thickness is 32mm, and the gross weight is 14kg. The casting (see Figure 1) needs to be set with 4 large risers for feeding due to the casting process (see Figure 2). As a result, the problem of which method to use to remove the four large risers of the casting arises. Originally, the casting was clamped on a vise. It is not easy to exert force, and it often happens that the hand is bruised. It has become a daunting process for the operator, and the work efficiency is low. Later, I thought that I could design a large riser sawing tooling and install the pump wheel casting on the T-mount. The tooling means Install it on the T table of the band saw machine, and use the band saw machine to remove the riser pot of the pump wheel.

1. Selection of band saw machine

The basis for the selection of the band saw machine is mainly to consider the maximum size of the pump wheel casting with 4 large risers (the size does not exceed o450mm). That is to say, it is equivalent to the size of the wood that the band saw machine can cut: and it must be set aside for easy loading and unloading. The space required for the workpiece should also be considered to be more convenient to install the sawing tooling. Therefore, the more common CH-800 band saw machine is selected. The size of the working table of this type of band sawing machine is 800mmx800mm, which is very suitable for the installation of guide rails and pot cutting tooling. Considering that the installation on one side of the workbench and the workpiece have a certain weight, it is necessary to set 2 reinforcing rods to support the workbench on the right side, so that the band saw is more stable when sawing.

2. Auxiliary equipment

The band saw machine sawing aluminum alloy is the same as sawing wood. Corresponding auxiliary equipment is also required for the opening, grinding and welding of the saw blade. The saw blade wears faster when sawing aluminum alloy than when sawing wood. Use auxiliary equipment. The frequency of equipment is also higher. In fact, the ANTISHI workshop has common auxiliary equipment such as saw blade gearing machine, saw sharpening machine and saw blade flash butt welding machine, which does not need to be repurchased.

3. Requirements for saw blades

The saw blade for sawing the aluminum alloy riser is slightly thicker than the woodworking saw blade. You can choose a steel plate of about 2mm and the material is 16Mn and cut it into strips. It is required to use a tooth opener to open the teeth 1~ 1.5mm, at the same time, the distribution in the interior should be finer, and the hand T. Saw road (the teeth are opened at an angle to the left and right plates), the angle of the woodworking saw blade does not need to be as large, but there must be a saw road, otherwise, sawing Easy to bite to death.

4. Operational matters

When sawing, the amount of sawing should not be too much, generally about 1mm is appropriate. When the riser 1 is sawed to 2/3 of the depth, reverse the trapezoidal screw to exit. Switch to the other side for sawing, and the end sawing is 1/3. Open the riser with a hammer, and use waste oil or lubricating oil to cold cut and lubricate the saw blade in sawing, and use a brush dipped in oil to brush the saw blade, so that the sawing effect is better.

5. Benefit

In the past, manual sawing of a pump wheel riser required relatively good labor, 2 people needed more than 20 minutes, and each pump wheel cost 1 manual hacksaw blade. Now, a CH-800 band saw machine is used to saw 1 pump wheel. It only takes 3 minutes for one person. The efficiency is increased by nearly 10 times in terms of time, and the labor is reduced by 1 person, and the labor intensity is greatly reduced. It is very popular with operators.