Wire cutting machine is a machine tool that uses the principle of electric spark discharge to generate pulse spark discharge between linear electrode wire (such as molybdenum wire, copper wire, etc.) and workpiece to erode the workpiece material to achieve processing.

So what are the main types of wire cutting equipment? What are their main differences? The Shanghai ANTISHICNC team will answer you below.

Wire cutting is mainly divided into three types: High Speed Wire Cut Electrical Discharge Machine, Middle -speed Wire cut Electrical Discharge Machine, Low Speed one-way walk Wire cut Electrical Discharge Machine, Their main differences are as follows:

| Differences features | High Speed Wire Cutting machine | Middle -Speed Wire Cutting machine | Low -Speed Wire Cutting machine |

| Wire Type | Molybdenum wire | Molybdenum wire | Copper wire |

| Electrode wire movement characteristics | High speed reciprocating motion | Reciprocating motion, wire speed is slower than fast wire | One-way low-speed movement |

| Wire speed | 8 – 10m/s | 3 – 5m/s | 0.2m/s or less |

| Conventional wire diameter | 0.12mm-0.25mm | 0.08mm-0.2mm | 0.05mm-0.3mm |

| Frequency of use | Multiple use | Multiple use | Single use |

| Processing efficiency | 4mm²/min | 50-18mm²/min | 100-50mm²/min |

| Processing accuracy | ±0.01 – 0.02mm | ±0.005 – 0.01mm | ±0.001 – 0.005mm |

| Surface roughness | 1.25 – 2.5μm | 0.8 – 1.6μm | 0.2 – 0.8μm |

| Application | Used for rough processing with low precision requirements, such as punching dies, templates, etc. | It is used in processing occasions that have certain requirements on precision and surface quality but need to control costs, such as complex-shaped dies and precision and small parts. | Used for processing parts with high precision and high surface quality requirements, such as precision molds, aerospace parts, etc. |

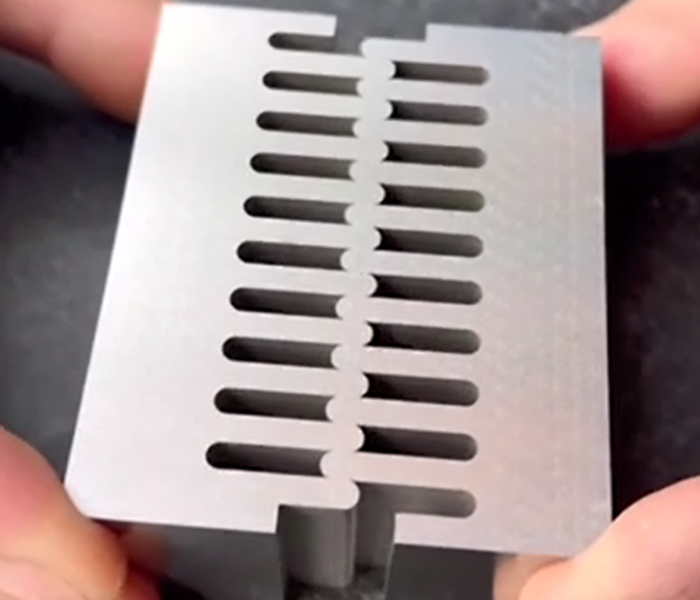

Sample picture of wire cutting processing:

|

|

|

The main application areas of wire cutting equipment are:

Mold manufacturing: It can be used to process the concave and convex molds of stamping molds, the cavity and core of injection molds, etc. For example, in the manufacturing of stamping molds for automotive parts, wire cutting can accurately manufacture mold parts that meet the design requirements to ensure the stamping accuracy and quality of automotive parts.

Mechanical processing: It is used to process various mechanical parts, such as gears, cams, splines, etc. In the fields of aerospace, weapons industry, etc., it is also used to process some high-precision and complex-shaped parts, such as the tenons of aircraft engine blades, precision parts of weapons, etc.

Electronic industry: It is used to process templates for printed circuit boards (PCBs), packaging molds for semiconductor chips, etc. These parts have extremely high requirements for precision and dimensional stability, and wire cutting can meet these requirements to ensure the performance and quality of electronic products.

Shanghai ANTISHICNC is specialized in the production and export of mechanical equipment. If you have any questions, please feel free to contact the Shanghai ANTISHICNC technical team!

Email information: contact@antsmachine.com