In the complex landscape of industrial manufacturing, the challenges of processing workpieces of varying materials constantly test the boundaries of technology and equipment. The hardness and brittleness of sapphire, the lightweight and porous nature of aluminum foam, and the heavy metal properties of flanges might seem incompatible with sawing. However, breakthroughs in specialized sawing technology are changing the answer. ANTISHICNC is deeply engaged in differentiated sawing scenarios, creating precise cutting solutions for these three types of specialized workpieces with customized machines, opening up new possibilities for sawing specialized materials. The following is an introduction to three Antis specialized machines:

1.Sapphire cutting saw

Sapphire’s high hardness (9 on the Mohs scale) makes traditional sawing machines prone to chipping and rapid blade wear. Dedicated sapphire sawing machines are equipped with specially ground diamond blades that exploit their high hardness. Combined with a high-precision servo system, these sawing machines precisely control cutting speed and feed rate to avoid thermal stress cracking. Data shows that these specialized sawing machines increase cutting efficiency by 3-5 times, raising yields from less than 50% to over 80%, driving application development in fields such as semiconductors and optics.

| Model | GZK4240 |

| Maximum cutting height | 450 mm |

| Maximum cutting diameter | Φ 350 mm |

| Saw blade linear speed | 800-1200 m/min |

| Worktable rotation speed | 0-50 r/min |

| Main motor power | 4 kw |

| Overall dimensions (length x width x height) | 2250 x 2000 x 1200 mm |

| Sawing capacity | 350 x 400 mm |

| Saw blade size | 0.7 x 38 x 3880 mm |

| Worktable feed speed | 0-500 mm/min |

| Saw blade rising and falling distance control accuracy | ± 0.10 mm |

| Cooling motor power | 0.06 kw |

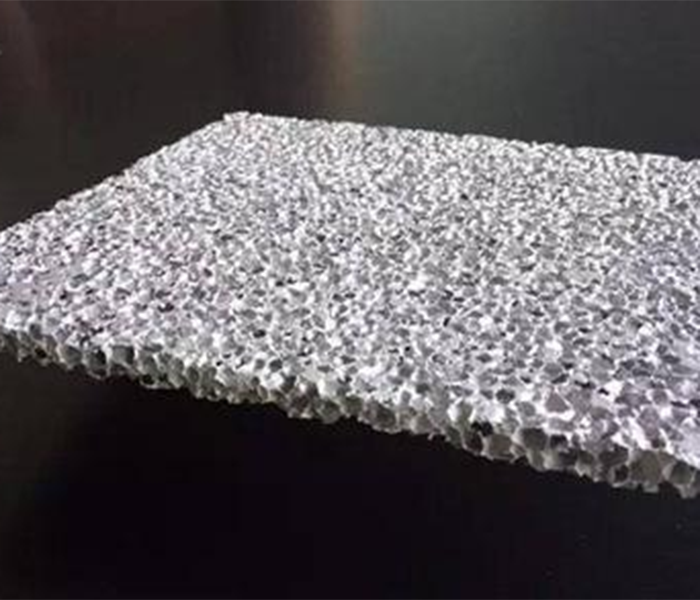

2.Aluminum foam slitting machine

The aluminum foam slitting band saw is a special cutting equipment developed by Antis based on the characteristics of aluminum foam, which is lightweight, porous, and easy to collapse and tear. It can accurately adapt to the needs of aluminum foam processing and is widely used in industrial scenarios that require aluminum foam material processing.

| Model | G4260/120/250 |

| Maximum cutting height | 600mm |

| Sawing speed range | 100-1000m/min |

| Main motor power | 15kw |

| Saw frame lifting motor power | 3.0kw |

| Horizontal worktable moving stroke | 2500mm |

| Servo motor power | 1.3kW (workbench movement) |

| Maximum cutting width | 1200mm |

| Saw blade specifications | 41×1.3x7530mm |

| Oil pump motor power | 0.75kw |

| Horizontal workbench specifications (width x length) | 1300X2700mm |

| Saw band tensioning method | Hydraulic tensioning |

| Overall dimensions (length x width x height) | 3600X5650X2600mm |

3.Flange sawing machine

The flange cutting band saw is a specialized cutting machine developed by Antis to address the heavy metal properties and diverse specifications (including large sizes and annular structures) of flanges. It can accurately solve the problems of difficult positioning, low precision, and poor efficiency when cutting flanges with traditional saws, providing professional solutions for flange processing and widely adapting to flange cutting needs in the industrial field.

| Model | GXK200 | |

| Maximum sawing specifications | 2000mm | |

| Minimum sawing inner diameter | 900mm | |

| Saw wheel diameter | Ø680mm | |

| Saw blade specifications | 54×1.6x7240mm | |

| Saw blade linear speed (stepless) | 20-60m/min | |

| Feed speed | 0-300m/min (servo) | |

| Disc rotation speed | 0-10r/min | |

| Distance of disk movement | 300min | |

| Saw frame feeding distance | 800mm | |

| Matching motor | Main motor (kW) | 5.5 |

| Oil pump motor (kW) | 1.5 | |

| Water pump motor (W) | 60 | |

| Oil tank capacity | Hydraulic box (L) | 200 |

| Coolant (L) | 50 | |

| Overall dimensions (length x width x height) | 3000X4000X3550mm | |

Sawing display

|

|

|

|

From highly brittle sapphire to loose aluminum foam to heavy flanges, Antis’s specialized sawing machines offer customized designs to meet diverse needs, safeguarding processing quality with precision sawing. In today’s industrial manufacturing landscape where specialized, precise, and unique features are paramount, this type of specialized equipment is not only the key to cutting specialized workpieces, but will also help other industries break through processing bottlenecks and move towards more efficient and precise production, injecting strong momentum into the large-scale and sophisticated processing of niche materials.

If you have any metal sawing needs, please contact the Shanghai ANTISHICNC team and we will have someone to contact you.

Official website: www.antsmachine.com

Email: contact@antsmachine.com

Keywords: Aluminum foam, Band sawing machine, Metal band sawing machine, Sapphire band sawing machine