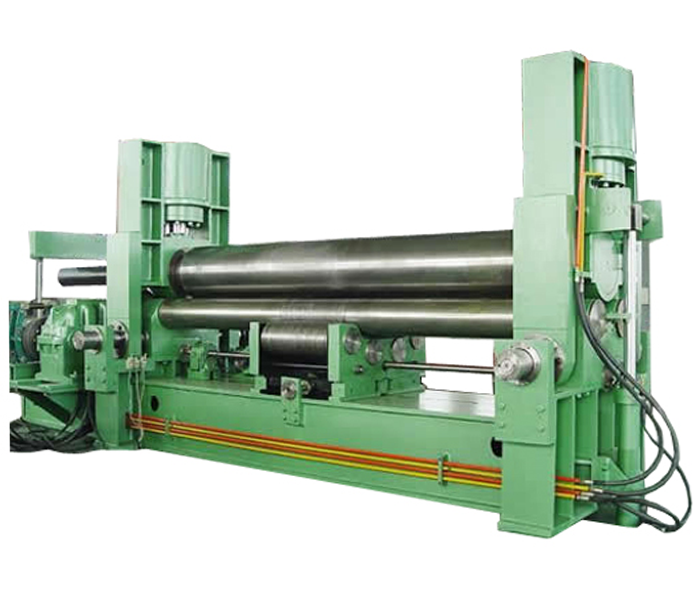

Plate rolling machines are mainly used to make the cylinder part (inner tank) of water heaters in water heater processing. During processing, the parameters of the hydraulic CNC plate rolling machine should be set according to the design size of the water heater cylinder. Then the plate rolling machine rolls the metal sheet (usually steel plate) into a cylindrical shape. There are the following processing steps in water heater manufacturing:

|

|

Plate rolling machines are mainly used to make the cylinder part (inner tank) of water heaters in water heater processing. During processing, the parameters of the hydraulic CNC plate rolling machine should be set according to the design size of the water heater cylinder. Then the plate rolling machine rolls the metal sheet (usually steel plate) into a cylindrical shape. There are the following processing steps in water heater manufacturing:

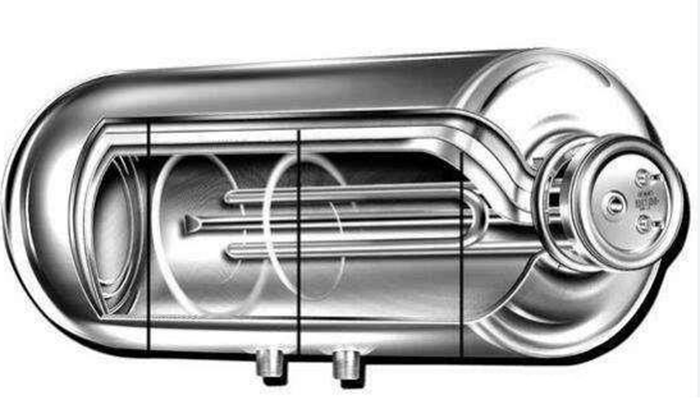

First, material preparation. The water storage water heater with a water tank is currently the most widely used household water heater. Its water tank shell is usually formed by cold-rolled annealed high-strength steel plate. The common thickness specification of the steel plate for the water heater tank cylinder is 0.4~0.7mm. After the steel plate is formed, it has a high strength to resist local deformation.

Then put the steel on the workbench of the hydraulic CNC plate rolling machine, and adjust the roller spacing of the CNC plate rolling machine so that the plate can smoothly enter between the rollers. After starting the plate rolling machine, the metal sheet gradually bends and deforms through the extrusion and rolling of the upper and lower rollers and is rolled into a cylindrical structure. In this process, according to the target diameter of the water heater cylinder, the movement of the rollers should be accurately controlled to ensure the dimensional accuracy of the curling. As the rollers continue to rotate, the sheet is gradually rolled into a cylindrical shape. For some water heater shells with special curvature requirements, different roller shapes and movement modes of the plate rolling machine can also be used to achieve this. For example, a cone rolling device can be added to the hydraulic upper roller universal plate rolling machine.

Finally, the cylinder of the preliminary rolled plate is fine-tuned and calibrated to meet the design requirements for roundness, diameter and other dimensional standards, and the rolling processing part of the water heater cylinder is completed. After that, other processes such as welding and installation of end covers are combined to finally make a complete water heater.

According to the common water heater tank size on the market, you can choose SHANGHAI ANTISHICNC company W11S-12*2500 hydraulic upper roller universal CNC three-roller plate rolling machine. The model reference is as follows:

| Model | W11S-12*2500 |

| Dia. of upper rollers | Φ270mm |

| Dia. of lower rollers | Φ150mm |

| Distance of the lower rollers | 245mm |

| No. of group of the support rolls | 1set |

| No. of the support rolls | 4 pieces |

| Upper roller down pressing speed | about 120mm/min |

| Driving speed | about 3.5m/min |

| Max rolling width | 2500mm |