The telescopic cylinder is a multi-stage hydraulic actuator and a special type of hydraulic cylinder. Its core feature is that it achieves long-stroke telescopic movement through a multi-section nested cylinder structure. It can maintain a small installation space in the retracted state, and can output a working stroke far exceeding its own retracted length when extended.

Recently, Shanghai ANTS Machine Equipment Co., Ltd. successfully received a customer from Turkey, a company that manufactures, develops, and sells automotive brake system components. The customer was an engineer who produces telescopic cylinders for truck cranes.

Telescopic cylinders for truck cranes primarily consist of end caps, a cylinder barrel, a piston rod, and a piston. Seals are installed between each component to prevent hydraulic oil leakage, and a buffer device is typically installed at the end.

The multi-stage piston design enables long-stroke telescopic operation within confined spaces, resulting in a compact structure. Furthermore, through rational design and manufacturing, it provides stable support, ensuring smooth and reliable crane boom extension and retraction. Some cylinders undergo special treatment for corrosion resistance, making them suitable for harsh operating environments.

The customer provided a detailed description of the dimensions of the telescopic cylinder he requested.

|

|

Key dimensions are as follows: cylinder diameter 560mm, rod diameter 480mm, and stroke 20,000mm. Maximum operating pressure reaches 42MPa, and each cylinder weighs approximately 1,500kg.

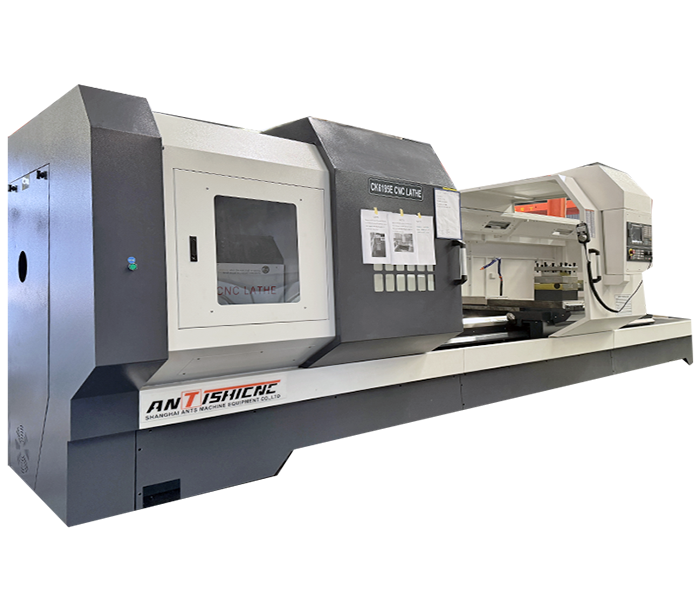

Shanghai ANTISHICNC engineers matched the customer with a suitable CNC lathe with a gearbox, an integral bed, and hard rails—the CK6185E/2000. This CNC lathe comes standard with a 620mm diameter hydraulic steady rest. This model can process a maximum diameter of 850mm and a maximum clamping length of 2,000mm. It meets the customer’s requirements for turning cylinder bodies, turning internal holes, drilling, boring, trepanning, and broaching oil grooves and keyways. Furthermore, the CK6185E/2000 is equipped with a hydraulic steady rest and has a load capacity of 1,800kg, while the telescopic cylinder weighs approximately 1,500kg. In short, based on various parameters, the CK6185E/2000 was ideally suited to the customer’s telescopic cylinder machining needs.

The following are the basic parameters of CK6185E/2000 CNC lathe:

| Basic parameters | Unit | CK6185E |

| Maximum turning diameter on the bed | mm | 850 |

| Maximum swing diameter on carriage | mm | 500 |

| Distance between centers | mm | 2000 |

| X/Z-axis rapid traverse | m/min | 4/5 |

| Tailstock quill diameter | mm | 100 |

| Rated total power | mm | 18 |

Next, our engineers will briefly introduce the general process for machining telescopic cylinders for truck cranes using a CNC lathe:

Ⅰ.Pre-Processing:

1.Material Selection

Cylinder: 27SiMn seamless steel tube (quenched and tempered, HB260-300)

Piston Rod: 42CrMo alloy steel (hardness HRC28-32 before hard chrome plating)

2.Process Design

Determine the machining sequence for each cylinder stage (processing from the inside out).

Draw the process card: Roughing → Semi-finishing → Finishing → Surface Treatment

Ⅱ.Main Processing Procedure:

1.Roughing (Removing Stock)

Clamping Method: Three-jaw chuck for one end, tailstock center for the other end.

Processing: External turning and internal boring

2.Semi-finishing (calibration)

Key Operations: End face turning, external finishing, and internal boring with a 0.2mm finishing allowance. Tool Selection: Rough Boring Tool and Finishing Tool

3.Finishing (Critical Dimensions)

Inner Hole Machining:

Use a diamond boring tool to control dimensions to H7 grade. Surface roughness reaches Ra 0.8μm.

External Hole Machining:

Complete in the same clamping as the inner hole, ensuring coaxiality ≤ 0.03mm.

4.Seal Groove Machining

Use a forming groove cutter for single-stage forming (avoiding tool marks). Groove Width Tolerance: ±0.02mm (e.g., 5.3 ±0.02mm)

For more detailed technical processing and machine details, please contact Shanghai ANTS Machine Equipment Co., Ltd. through our website. Our engineers will match you with the most efficient and suitable machine and provide professional service.

Machine Tool Official Website: