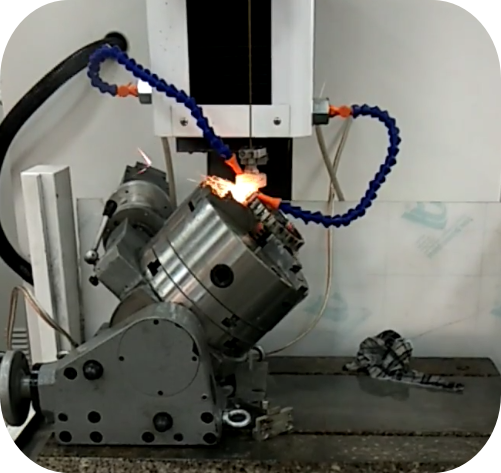

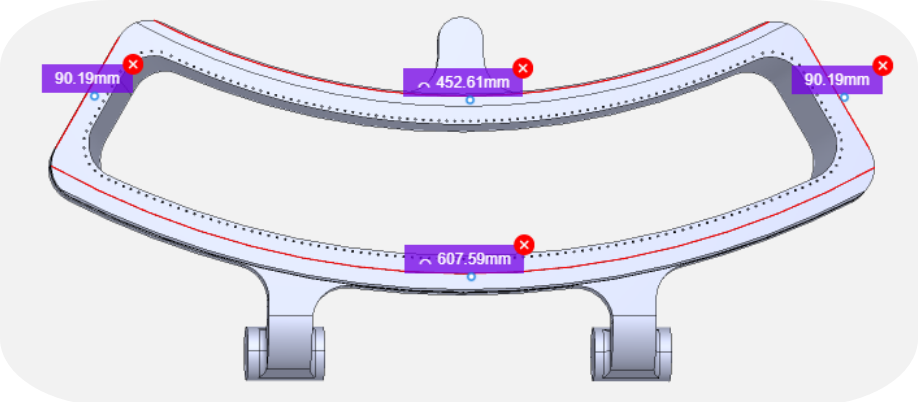

Shanghai ANTISHICNC Company has a Malaysian customer who customized an EDM multi-axis punching machine to process the aircraft engine blade mounting frame this month. As shown in the picture above, the size of the aircraft engine blade mounting frame is about 610mm long and 120mm wide. The thickness is 65mm, and need to process small holes of 0.2-3mm in the drawing. After Shanghai ANTISHICNC engineers technical research and discussion, we finally customized the SK703-8A CNC EDM multi-axis Drilling machine for this customer. The spindle head of this equipment is designed to swing at an angle of ±110°. And in one clamping and positioning, all holes with different spatial angles and positions can be processed. The equipment has achieved 6-axis linkage. The following are the main parameters of the customized stroke of the equipment:

| Parameter | Unit | Unit | |

| X-axis travel | 800mm | Control equivalence | 0.001MM |

| Y-axis travel | 1000mm | Control equivalence | 0.001MM |

| Z-axis travel | 400mm | Control equivalence | 0.001MM |

| S-axis travel | 400mm | Control equivalence | 0.001MM |

| W-axis travel | 250mm | Control equivalence | 0.001MM |

| A-axis rotation range | 360º(250mm) | Control equivalence | 0.001° |

| B-axis swing range | ±110° | Control equivalence | 0.001° |

In order to complete the automatic processing of small holes at different positions of the specified workpiece, this CNC Drilling Machine has a total of 8 motion axes. The main machine adopts a C-shaped structure, and machine bed is made of high-quality castings. High-strength body structure is integrally cast using resin sand technology. This EDM machine workbench is equipped with X, Y, and axes to complete the transposition of positions of each hole. The column is equipped with a Z-axis and B-axis spindle heads to complete the adjustment of frame hole at different angles in the vertical plane.Spindle head is also equipped with W, S, and R axes, which are used to complete the servo feed of the electrode during processing; adjustment of the position between the guide and the workpiece; rotation of the electrode during processing, high-voltage liquid conduction, rotation feed, and electrode rotation. Clamping.

| 5 axis CNC EDM DRILLING PROCESSING | Aircraft Engine Blade Structure Frame |

|

|

The EDM Drilling machine is equipped with a water conductivity automatic control working fluid system, which automatically detects and processes the conductivity of water, and also improves the accuracy and reliability of the machine tool’s movement position.

For more customized solutions, please contact Shanghai ANTISHICNC Machinery Equipment Co., Ltd. We provide customers with timely technical support, training and spare parts supply!

EDM punch machine official website: https://www.antsmachine.com/edm-drill/

Keywords: EDM machine,EDM Drilling machine,CNC Drilling Machine