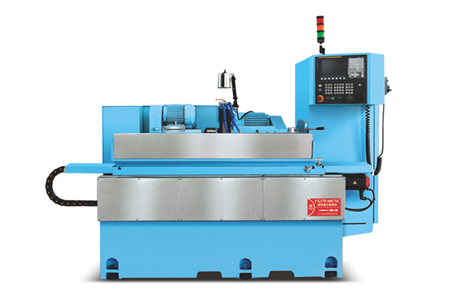

CNC cylindrical grinder is a kind of machine tool that uses molds to process base parts. For base or metal parts with higher hardness, the effect of CNC cylindrical grinder is more prominent. As a result, fastener standards often use some high-hardness metals and other raw materials for processing and production, and CNC cylindrical grinders are also commonly used in the fastener industry.

If we can achieve a more standardized operation in normal use, and pay attention to the daily maintenance and maintenance of the machine, we can effectively reduce the failure of the CNC cylindrical grinder and improve the work efficiency.

Steps for correct operation and use of CNC cylindrical grinder:

Inspection before powering on CNC cylindrical grinder:

1) Check whether each printed circuit board in the CNC cylindrical grinder is tight and whether each plug is loose.

2) Carefully check whether all the connecting cables between the CNC cylindrical grinder and the outside world are correctly and reliably connected according to the provisions of the connection manual provided.

3) Whether the connection of AC input power meets the requirements of CNC cylindrical grinder.

4) Confirm whether the various hardware settings in the CNC cylindrical grinder meet the requirements. Only after the above inspection, the CNC cylindrical grinder can be put into operation.

Inspection of CNC cylindrical grinder after power-on:

1) First, check whether each fan in the CNC cylindrical grinder is operating normally.

2) Confirm whether the DC power supply on each printed circuit or module is normal and whether it is within the allowable fluctuation range.

3) Further confirm the various parameters of the CNC cylindrical grinder.

4) When the CNC device and the machine tool are powered on, the imported pump should be connected to the power supply as a preparation for pressing the emergency stop button, so as to cut off the power at any time in case of emergency.

5) Manually move each axis at a low speed, and observe whether the display of the movement direction of the CNC cylindrical grinder is correct.

6) Perform several operations of returning to the machine reference point to check whether the CNC cylindrical grinder has the function of returning to the reference point, and whether the position of the reference point is exactly the same each time. (4 major maintenance makes the CNC cylindrical grinder more durable)