Shanghai ANTISHICNC Company has sorted out the following 4 methods for CNC lathe thread processing :

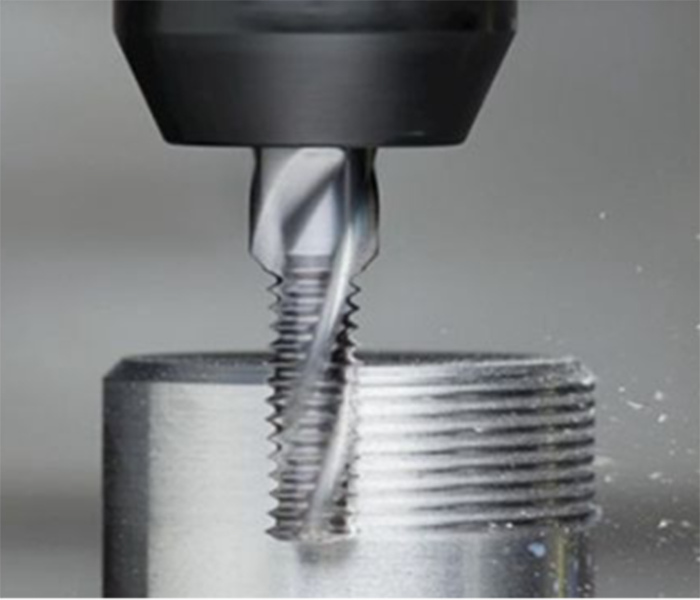

1.CNC lathe tapping

Tapping is a common method in CNC lathe thread processing, which mainly uses a tap to cut threads on the hole wall. Tapping requires the use of tools such as taps and drills.

First, use a drill to punch a hole of corresponding specifications on the workpiece, then insert the tap into the hole, and cut the thread by rotating the tap or workpiece. Tapping has high precision and efficiency, and is suitable for thread processing of various materials and specifications.

2.CNC lathe threading

CNC lathe thread turning is an efficient and high-precision thread processing method. Using the high-speed spindle and high-performance tool system of the CNC machine tool, the thread processing is carried out at a speed and feed speed far higher than the traditional cutting speed. Before threading, you need to install the tool and workpiece first, and adjust the parameters of the lathe.

Then, the thread is cut by rotating the tool or workpiece. Thread turning lathes can process threads of different specifications and materials with high precision and efficiency, which can significantly improve processing efficiency and reduce processing costs. At the same time, they can improve the surface quality of threads and reduce processing deformation. However, they have high requirements for the clamping of machine tools, tools and workpieces. They are suitable for processing threads with large batches and good material cutting performance.

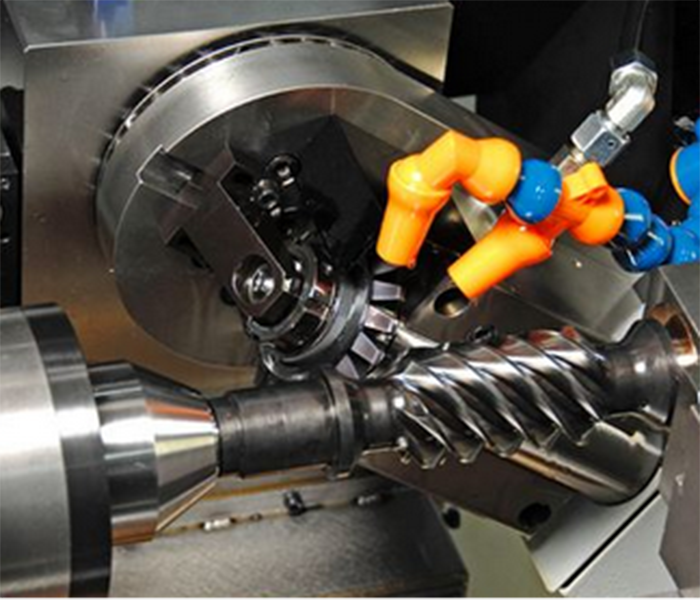

3.CNC latheWhirlwind Milling

Whirlwind Milling is a relatively special CNC lathe thread processing method. It uses a carbide tool installed on a whirlwind milling cutter disc to make a relative spiral motion with the workpiece while rotating at high speed to achieve the milling of threads.

The advantage of whirlwind milling is that the processing efficiency is extremely high, which is several times or even dozens of times higher than that of traditional lathe thread turning methods, and the cutting speed is fast, which is suitable for large-scale production. However, whirlwind milling requires the use of special milling cutters and fixtures, which are more expensive and are often used to process threads with large pitches, long threads and difficult-to-process materials.

4.Rolling thread on CNC latheMachine

Rolling thread is to squeeze the surface of the workpiece by rolling the rolling wheel to form a thread shape. The advantage of thread rolling is that it can produce high-precision threads with low surface roughness, which can improve the tightness and wear resistance of the connection. However, thread rolling requires the use of special rolling wheels and fixtures, which are more expensive.

| Tapping | Thread turning |

|

|

| Whirlwind Milling | Rolled thread |

|

|

The above are several common CNC lathe thread processing methods, each of which has its own characteristics and scope of application. In actual production, it is necessary to select the appropriate processing method according to the specific situation to ensure the processing quality and efficiency of the thread. At the same time, it is also necessary to pay attention to the safe operation and maintenance of the lathe to ensure the smooth progress of production.

Welcome to your consultation!

Keywords: Lathe, CNC lathe, Thread turning machine, Thread turning lathe