The automatic diamond grinding wheel dressing machine is a professional equipment used for dressing grinding wheels. It integrates a variety of advanced technologies such as mechanical, electrical, and numerical control. It mainly uses preset programs and parameters to automatically control dressing tools to perform precise dressing operations on the grinding wheel without excessive manual intervention. The equipment usually consists of control system, drive system, dressing tools, machine bed and other parts. The control system is like the “brain” of the equipment, responsible for setting and adjusting dressing parameters, planning dressing paths, etc.; the drive system provides power for the relative movement of the dressing tool and the grinding wheel to ensure the smoothness and accuracy of the movement; while the diamond dressing tool Effective dressing of grinding wheels thanks to its high hardness. Automatic grinding wheel dressers are widely used in mechanical processing, tool manufacturing, automobile manufacturing, aerospace and many other fields. They can significantly improve the dressing accuracy and efficiency of the grinding wheel, extend the service life of the grinding wheel, thereby improving the processing quality and production efficiency of the product, reducing the production costs.

Recently, the ANTISHICNC team received an inquiry for a grinding wheel dressing machine. The customer is a white corundum and silicon carbide grinding wheel factory. They are looking for an automated equipment to achieve more efficient grinding wheel dressing work. Currently, customers use a grinding wheel dressing pen to make manual corrections.

| Grinding wheel dressing pen | Grinding wheel to be dressed |

|

|

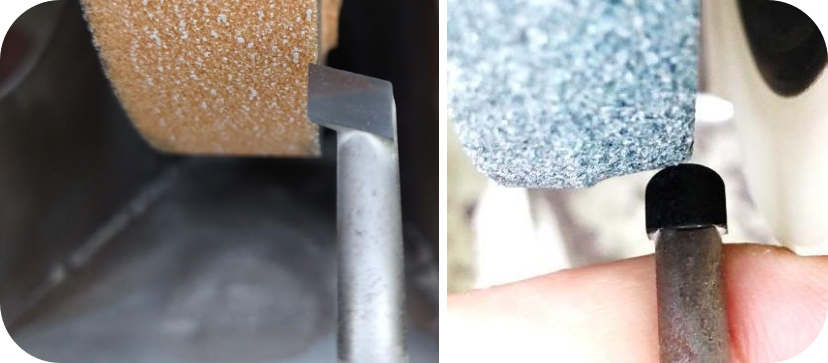

| Customer’s grinding process | |

|

|

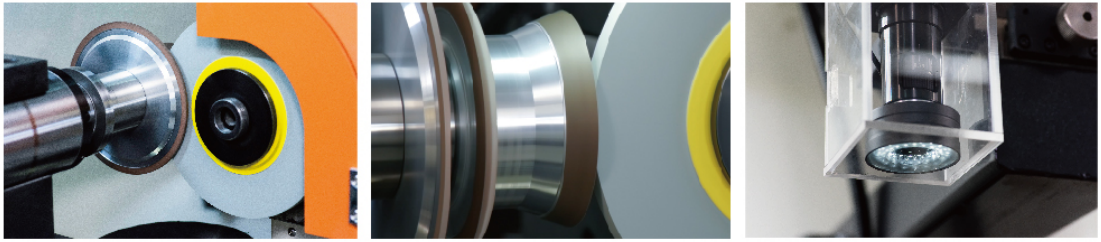

According to the customer’s needs, we recommended the CNC diamond wheel dresser X6 of Antis Machinery Equipment to the customer, and suggested that he use diamond grinding wheels to improve the dressing efficiency. The following introduces the product technical features and grinding capacity of the grinding wheel dresser of ANTS Machinery Equipment Co., Ltd.:

1.Two-axis electronic handwheel control + three-axis linkage CNC grinding wheel dressing system

2.The inner side, outer side, outer side, angle and arc of the grinding wheel can be trimmed

3.Silicon carbide grinding wheel SIC can automatically rotate, reciprocate, automatically feed and automatically trim

4.Optional zoom lens or fixed-focus zoom lens and high-resolution camera, clear imaging and accurate measurement

5.One-click import of CAD drawings;

6.10mm acrylic sealing cover is safer, more environmentally friendly and neater.

| Specifications | X6 CNC diamond wheel dressing machine |

| Dressing wheel spindle | Standard BT40 interface spindle, optional customer interface spindle |

| Dressing wheel outer diameter | 30~300mm |

| Grinding method | Dry repair, water mist repair, wet repair |

| Dust collection device and grinding fluid filtration system | Optional |

| Power supply voltage | Three-phase 380V/50HZ |

| Total power | 3KVA |

| Maximum dressing wheel diameter | φ300mm (super large customizable) |

| Minimum dressing wheel diameter | φ30mm (super large customizable) |

| Maximum dressing wheel width | 40mm (super large customizable) |

| Dressing wheel speed | 50~1000rpm (stepless speed change) |

| Dressing wheel X-axis left and right movement distance | 135mm (can drag the grinding wheel spindle seat, increase the stroke to 300) |

| Dressing wheel Y-axis forward and backward movement distance | 100mm |

| Dressing wheel (silicon carbide) diameter | φ200 (or φ250)×10x 31.75mm |

| Dressing wheel (silicon carbide) speed | Maximum 2800rpm (continuously variable speed) |

| Dressing wheel (silicon carbide) swing times | 0~50Hz (continuously variable speed) |

| Dressing wheel (silicon carbide) swing length | 0~50mm (adjustable) |

| Grating scale (magnetic scale, angle scale) resolution | 0.001mm/0.01° |

| CCD and lens | Standard ordinary lens, optional HD camera, variable or fixed magnification HD lens |

| Upper light source | LED light |

| Backlight source | Large-aperture backlight technology |

| Computer host, high-definition LCD screen | 1 set |

| Computer measurement system | 1 set |

| Magnification | Optional |

| Measurement function | Real-view image and CAD image can be zoomed in simultaneously for pressure line comparison |

| Data display | The position of the grinding wheel being trimmed can be displayed on the measurement software |

If you have similar processing needs, please feel free to consult Shanghai Antis Machinery Equipment. We have rich experience in manufacturing and using diamond grinding wheel dressing machines, and can provide you with professional technical support! At the same time, we can also provide a variety of CNC five-axis tool grinders, suitable for processing turning tools, milling cutters, woodworking production drills, twist drills, tungsten steel tools, etc. Shanghai ANTS Machinery Equipment Co., Ltd. is your one-stop service provider for tool production. For details, please contact contact@antsmachine.com.