Five-axis linkage CNC machine tools are a key component of current high-end machine tools. They refer to the basic linear axis of the machine tool, two of the three axes X/Y/Z and the additional rotation axis A/B/C. The five axes move simultaneously. Arbitrarily adjust the position of the tool or workpiece to process complex spatial surfaces. Compared with ordinary CNC machine tools that use three-axis and four-axis linkage, its advantage is that it has higher processing accuracy, is suitable for more complex processing scenarios, and can meet more efficient and dynamic processing methods. Among them, the five-axis linkage vertical machining center is a machine tool with high technological content and high precision specially used for processing complex curved surfaces. This machine tool is very important for a country’s aviation, aerospace, military, scientific research, precision instruments, and high-precision medical equipment. and other industries, has a decisive influence.

Five-axis linkage vertical machining centers are mainly used in the following industries:

1.Aerospace industry: It has the advantages of high precision and high efficiency , and can be used to process complex parts in the aerospace field. For example , aircraft engine turbine blades, combustion chambers, nozzles, etc.

2. Automobile manufacturing industry: The manufacturing of auto parts requires high-precision and high-efficiency equipment. It can be used to process complex parts such as cylinder blocks, cylinder heads, crankshafts, and connecting rods of automobile engines. It can also be used to process automotive chassis, suspension systems and other parts that require high precision, high strength and lightweight .

3. Energy industry: It can be used to process complex parts in nuclear power, wind power and other energy equipment. For example , the fuel rods and control rods of nuclear reactors require high-precision and high-efficiency processing.

4. Medical device industry: It can be used to process high-precision parts in medical devices, such as surgical instruments, implants, etc. It can also be used to process high-precision, high-reliability medical equipment such as artificial joints and artificial hearts.

5. Mold manufacturing industry: Mold manufacturing requires high-precision and high-efficiency equipment. It can be used to process various complex molds, such as injection molds, die-casting molds, etc.

6. Semiconductor industry: It can be used to process high-precision parts in semiconductor equipment, such as wafer cutting machines, chip packaging machines, etc. It can also be used to process high-precision parts in optical components and optical systems.

Our company has several five-axis linkage vertical machining centers. Among them, X-link 500 is suitable for precision machining of small workpieces. It has X, Y, Z axes, linked B-axis and C-axis; X-link 630 is suitable for medium-sized workpieces. Precision machining is X, Y, Z axes, linked A axis and C axis. Recently, we received the customer’s processing drawings. After verification by our professional engineers, we recommended the X-link 500 five-axis linkage vertical machining center to the customer, which can process all workpieces of the customer’s drawings.

|

|

| Five-axis linkage vertical machining center | Internal structure of five-axis linkage vertical machining center |

|

|

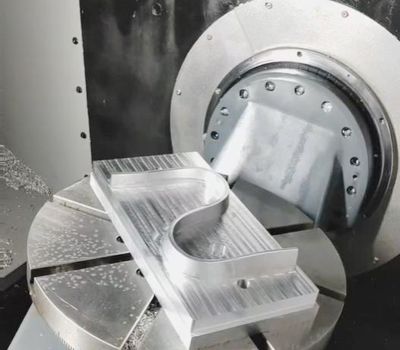

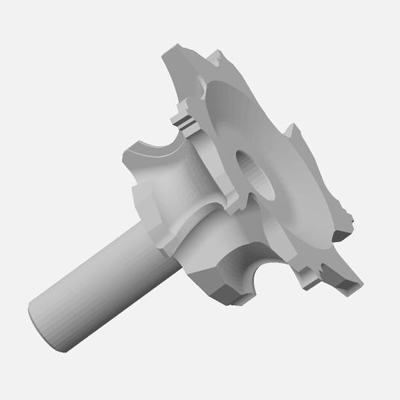

| Five-axis linkage machining legend | Internal structure of five-axis linkage vertical machining center |

|

|

| Processing legend 1 | Processing legend 2 |

Our Shanghai ANTISHICNC company’s machining center models come in various categories, including standard 3-axis vertical machining centers, such as: VMC650, VMC850, VMC1160, etc., which can be equipped with 4-axis turntables and other CNC systems, and there are also five-axis machining centers. The axis-linked vertical machining center , equipped with the latest domestically developed CNC system, can perfectly process various difficult workpieces. If you have any needs for a five-axis linkage vertical machining center, please feel free to contact our sales engineer.