Technical Parameter

| Specifications | Unit | TCK50A/500 | ||

| Max. rotary diameter on the bed | mm | Φ560 | ||

| Max. swing diameter on the slip board | mm | Φ260 | ||

| Distance between centers | mm | 500 | ||

| Max. disc processing diameter | Φ400 | |||

| Max. turning length | mm | 500 | ||

| Spindle end type | A2-6 | |||

| Spindle through hole diameter | mm | Φ66 | ||

| The rod material path | mm | Φ55 | ||

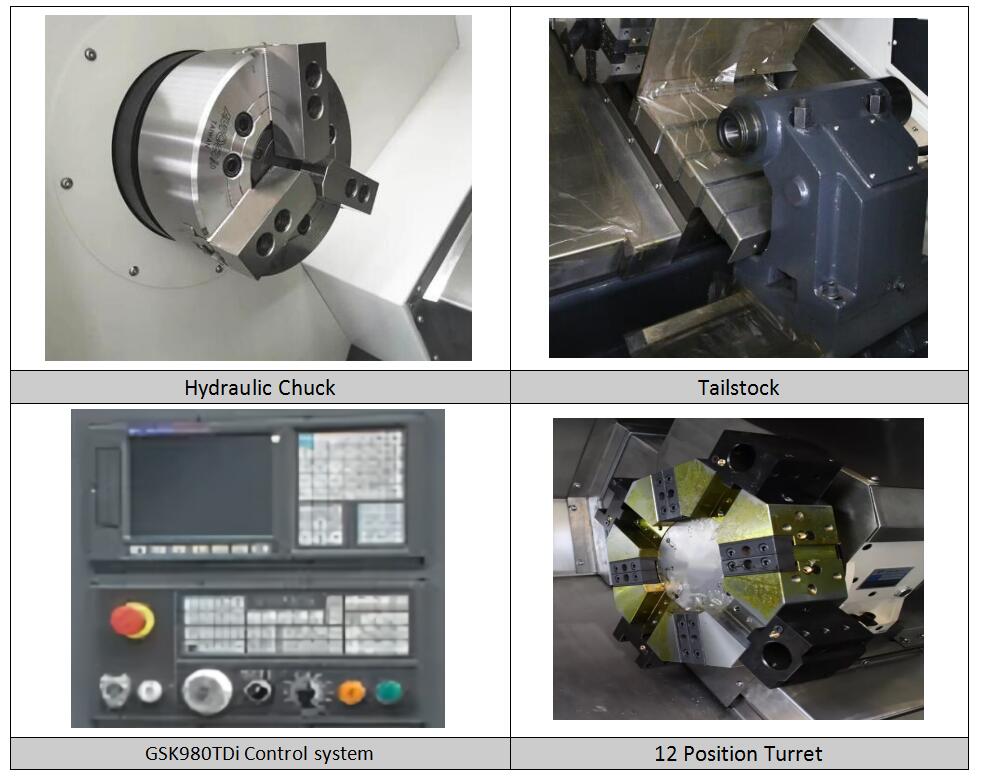

| Oil hydraulic chuck | mm | 10 Inch | ||

| Through-hole diameter of Hydraulic clamping rod | mm | Φ55 | ||

| Guide track form | linear guide rail | |||

| The cone aperture of the spindle | No | Metric system: 70 1:20 | ||

| Spindle limit speed | rpm | 3000rpm | ||

| Tail seat sleeve diameter | mm | 70 | ||

| Taper of inside hole of tail seat sleeve | No | Moss 5 # | ||

| Tail seat sleeve trip | mm | 80 | ||

| Tail seat form | hydraulic pressure | |||

| Turret post | 12 position | |||

| The Tool square size | mm | 2525´1114 Æ40 | ||

| Silk bar model | X direction | 3210 | ||

| Z direction | 4010 | |||

| Guide rail model | X direction | RGH35CA 2R680 | ||

| Z direction | RGH35CA 2R1120 | |||

| X / Z motor torque | N.M | 7.5/10 | ||

| X / Z fast speed | m/min | 18/18 | ||

| X axis travel | mm | 240 | ||

| Z axis travel | mm | 540 | ||

| Mini. setting unit | mm | 0.0001 | ||

| Power of main motor | KW | 11 | ||

| Total power supply | KW | 18 | ||

| Machine tool net weight | Kg | 3000 | ||

| Overall dimension (L*W*H) | mm | 2700*2000*2000 | ||

| Periodic axial movement of the main axis | mm | 0.005 | ||

| Spindle chuck positions the radial beating of the cone surface | mm | 0.005 | ||

| Positional accuracy | Repeat positioning accuracy A | ±0.005 | ||

| Diameter consistency | 0.01/150 | |||

| Flatness | 0.025/φ300 | |||

| Threaded pitch product error | mm | 0.010/100 | ||

| Surface roughness | Ra | Ra1.6μm | ||

Equipment Introduction

The TCK50Acan process cylindrical surface, cone surface, circular arc surface, cut slot and cut off, and can also process the direct thread, taper thread and so on.

The TCK50AHeavy duty Horizontal metal working turning cnc lathe machine the traditional horizontal lathe layout and the overall design.CNC lathe driven by microcomputer control and servo motor.

Characterized by easy operation, compact structure, beautiful appearance, stable performance, high accuracy and low noise.

The spindle, brake and translocation tool holder of the servo motor, the lathe by sending and receiving signals.

The independent main axis can control the variable frequency motor speed to be infinitely variable speed by inverter, and the feed speed can be arbitrarily set, thus realizing automatic processing controlled by microcomputer.

Spindle adopts high precision rolling bearings, high precision rotary plate aspect to adopt high precision ball screw transmission, good dynamic performance, precision positioning.

The machine tool guide with wear-resistant cast iron and after the audio quenching, the hardness of the HRC45 above, can ensure the long-term stability of processing accuracy.

High rigidity pedestal and wider lay board are suitable for heavy cutting

The TCK50Acan be operated automatically and manually, with semi-automatic control of knife, tool compensation and gap compensation, equipped with hardware, software limit and other functions.

The lathe can be used to increase hydraulic chuck, and other numerical control system according to user’s requirements.

These series lathes operate on power supply of different voltages (220V,380V,420V) and different frequencies (50HZ,60HZ).

Standard Equipment

| Name | Specifications | Quantity | Manufacturers | |

| Control system | 980TDi | 1 set | GSK | |

| Spindle motor | 11KW | 1 set | CTB | |

| Spindle unit | 200-282/5-3V | 1 set | GSK | |

| main shaft bearing | NN3020K+MTM100/ NN3018K | Each 1 set | Harbin | |

| Guide rail | X direction | RGH35CA 2R680/725 | 1 set | HIWIN&PMI |

| Z direction | RGH35CA 2R1040/1120/1515 | Each 1 set | HIWIN&PMI | |

| Ball screw | X direction | 3210/703 | 1 set | HIWIN&PMI |

| Z direction | 4010/965/1052/1429 | Each 1 set | HIWIN&PMI | |

| The bar bearing | 25TAC62/30TAC62 | Each 2 sets | NSK | |

| DOTA | TX -200-8T/TCS-100-8T | 1 set | Taiwan, China | |

| Automatic lubrication installation | RBCLB-3ZK | 1 set | ANTISHI | |

| Cooling pump | 180W | 1 set | ANTISHI | |

| Hydraulic pressure station | 1.5kw | 1 set | ANTISHI | |

| Oil chuck | KT 0-3/A2-6;KT 0-3/A2-8 | 1 set | ANTISHI | |

| Plambing machine | Chain plate type (optional) | 1 set | ANTISHI | |

List of Documents

| No | Name | Quantity |

| 1 | Packing list | 1 |

| 2 | Certificate of conformity

(including accuracy inspection list) |

1 |

| 3 | Operating instruction | 1 |

| 4 | CNC system instructions | 1 |

| 5 | Electric knife holder manual | 1 |

| 6 | Frequency converter instruction manual | 1 |

| 7 | Motor instruction manual | 1 |

| 8 | Drive instruction manual | 1 |

| 9 | Oil pump instruction manual | 1 |

More Product Details