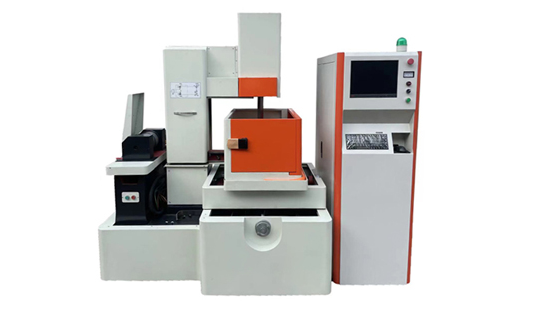

Due to the large market demand for wire cutting machine tools, the quality of wire cutting machine tools on the market is also mixed. The wire cutting machine tool is the last process in the mold processing, and it is also an important step, so the processing accuracy must meet the requirements. Therefore, the precision of the wire cutting machine should be high, otherwise it will affect the quality of the mold. When consumers choose a machine tool, they should not only understand the function of the machine tool, but also understand its structural advantages and disadvantages, and whether the accuracy meets the standard.

Generally speaking, the accuracy of WEDM machine tools is easy to judge, because there are national standard GB7926-87 and related general standards for machine tool accuracy, you can know whether it is qualified or not when the new machine tool is commissioned and accepted. However, the important thing is to judge the accuracy of the machine tool, because the accuracy of the machine tool can only be reflected when the machine tool is used for a certain period of time, and the standard cannot strictly control it quantitatively, so only It is the user’s own in-depth and detailed understanding of the machine tool and structure when selecting models.

The accuracy of the screw is very important, but if the installation structure of the screw is unreasonable, no matter how good the screw is, it will not help. Ball screws are currently used on wire cutting machine tools, and the diameter of the screw is required to be as reasonable as possible to increase rigidity. The second is the installation structure of the lead screw, and the ball screw is a transmission component. Therefore, in order to give full play to its performance, the assembly structure of the lead screw is also required to be high. Both ends must be fixed and supported by bearings, thereby improving the machine tool table. Movement Accuracy.

For the transmission structure of ball screw and motor, we must first understand the transmission structure in detail. At present, gear transmission is still used in most of the middle thread in the market. This kind of transmission is prone to gear gaps, which leads to large system errors of the machine tool table. Therefore, when selecting models It is very important to have an in-depth understanding of the transmission structure of the table motion. Today’s machine tools are directly driven by ball screws and motors. The gear gap error is reduced and the machining accuracy is improved. This is critical for machine tool accuracy retention.

The structure of the guide rail, the guide rail is the key to ensure the movement accuracy of the worktable, and the user should pay great attention to it when selecting the model. Basically, linear linear rolling guides are used now. Directly observe the rail mounting structure. Ordinary CNC wire cutting machine tools are generally driven by stepper motors, and there are reactive and hybrid types in stepper motors. The most common in the market is reactive stepper motors. With the continuous improvement of market demand, now The medium wire cutting machine should be equipped with a hybrid or AC servo drive system. Ensure smooth and powerful transmission. Guaranteed cutting accuracy.

In summary, the worktable of the wire cutting machine tool must adopt a full support structure to improve the rigidity of the machine tool to ensure heavy load without deformation and ensure cutting accuracy. Linear guides are used to ensure good sensitivity and motion accuracy in the cutting motion. Choose a ball screw with a reasonable diameter as possible, and have fixed bearing support structures at both ends; it is better that the drive screw of the worktable and the motor are directly connected to reduce the gear gap and ensure the cutting accuracy.