Shearing, bending and stamping are traditional sheet metal processing technologies. Their shortcomings are that they require molds for mass production in actual applications, which is time-consuming and costly, and it is difficult to guarantee accuracy and quality. In order to improve this situation, modern sheet metal processing mostly chooses laser cutting to make up for the shortcomings of traditional sheet metal production. Shanghai Antis laser cutting has the following three advantages:

|

|

Shearing, bending and stamping are traditional sheet metal processing technologies. Their shortcomings are that they require molds for mass production in actual applications, which is time-consuming and costly, and it is difficult to guarantee accuracy and quality. In order to improve this situation, modern sheet metal processing mostly chooses laser cutting to make up for the shortcomings of traditional sheet metal production. Shanghai Antis laser cutting has the following three advantages:

1.Optimize the process and reduce the difficulty and intensity of work

Shanghai ANTISHICNC company laser cutting machine reduces the use of molds and the time for mold replacement. Through the application of laser cutting machines, aluminum veneer sheet metal processing workpieces can be directly welded and assembled, realizing the processing method from “casting” to “welding”, optimizing the processing process, thereby reducing the cutting time of aluminum veneer sheet metal while reducing the processing difficulty and reducing the intensity of work. At the same time, since the application of this technology can effectively reduce the use of molds, it can promote the smooth development of product development and design work, and can effectively reduce the time of its application, thereby providing a convenient prerequisite for the research and development of new products. Therefore, this technology can be applied to the processing and production of some small batches of workpieces to shorten the product manufacturing cycle, and strictly control the size of the blanking die, so as to facilitate the smooth production of large batches of workpieces in the future.

2.Improve the efficiency of processing work and the quality of processed workpieces

Laser cutting technology is a very advanced process technology. Through the analysis of its processing principle, it can be seen that it can reduce the processing time with its high-precision, fast and accurate cutting technology, and it is often formed in one step in sheet metal processing operations, which improves the utilization rate of materials and other resources and improves work efficiency. In addition, since laser cutting technology has the characteristics of small slits, fine density, smooth incision parts, and can complete the cutting operation in a short time, it can improve the processing efficiency while enhancing the quality of the processed workpiece, thereby providing a solid quality guarantee for its further use. Therefore, in sheet metal processing, the advantages of laser cutting technology should be fully utilized to smoothly carry out high-precision and high-quality processing work.

3.Reduce processing costs

The laser cutting machine of Shanghai ANTISHICNC Company efficiently uses the advantages of CNC programming software to strictly control the processing materials and improve the utilization rate of aluminum veneer sheet metal materials, thereby achieving the optimal configuration of aluminum veneer sheet metal, reducing waste, and reducing the number of clamping times, thereby helping enterprises reduce sheet metal processing costs. Therefore, when performing sheet metal processing operations, the effective application of CNC programming related software should be continuously strengthened for the processing of thin plate materials, and its function of optimizing material arrangement should be fully utilized, thereby omitting the cutting process and reducing clamping to successfully complete the sheet metal processing operations.

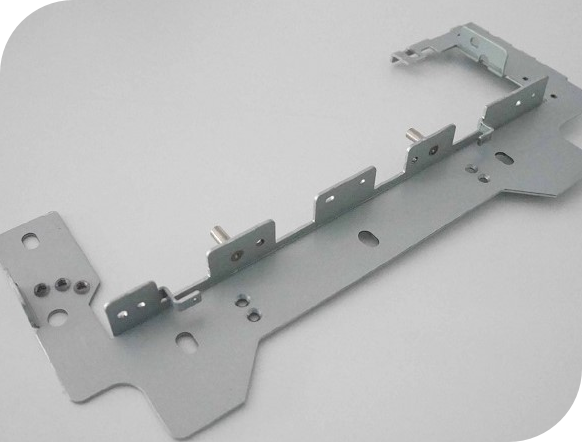

The following are the reference models for customers of Shanghai ANTISHICNC when processing aluminum veneer sheet metal:

| Model | Thickness[mm] | Speed[m/min] | Power [W] | Gas | Pressure [bar] | Nozzle[mm] | Focus position [mm] | Cutting height[mm] |

| 3300W | 1 | 20-25 | 3300 | N₂ | 12 | 1.5S | 0 | 0.8 |

| 2 | 10-15 | 12 | 2.0S | -1 | 0.5 | |||

| 3 | 6-8 | 14 | 2.0S | -1.5 | 0.5 | |||

| 4 | 4-5 | 14 | 2.0S | -2 | 0.5 | |||

| 5 | 2-3 | 16 | 3.0S | -2.5 | 0.5 | |||

| 6 | 1.5-2 | 16 | 3.0S | -3 | 0.5 | |||

| 8 | 0.6-0.8 | 16 | 3.5S | -4 | 0.5 |