The movable beam CNC gantry boring and milling machine is an advanced large-scale CNC processing equipment. Its main feature is the movable crossbeam. The crossbeam can move up and down on the column. It is driven by transmission devices such as motors, screws, and nuts to achieve the lifting movement of the crossbeam. The position of the crossbeam can be flexibly adjusted according to the height of the workpiece to meet the processing needs of workpieces of different sizes.

Mainly used in the following fields:

1.Aerospace: used to process large and complex parts such as aircraft wing beams, fuselage frames, engine casings, etc.

2.Shipbuilding: can process large gearbox housings, marine engine cylinders, propeller hubs and other parts.

3.Energy and power: often used to process large parts such as hubs and bases of wind turbines, as well as bases and shells of turbines and steam turbines.

4.Mold manufacturing: can perform high-precision processing on cavities and cores of large injection molds and die-casting molds.

Recently, Shanghai ANTISHICNC received an inquiry from a foreign equipment manufacturer. They needed a gantry boring and milling machine to process their large bed. Through the customer’s drawings and other information, as well as a year-long technical parameter confirmation and function communication, we finally selected the XKW2137x60 movable beam CNC gantry boring and milling machine for the customer.

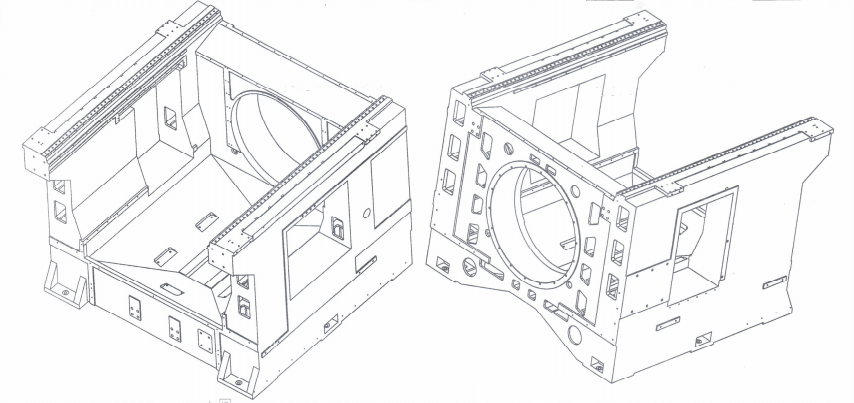

Part of the customer’s drawing information:

The XKW2137 movable beam gantry boring and milling machine is a heavy-duty mechanical processing equipment that integrates advanced mechanical, electrical, and hydraulic technologies. The overall structure of the machine tool adopts a gantry frame to fix the crossbeam, the crossbeam moves up and down along the left and right column guide rails (W axis), the ram type milling and boring spindle box moves horizontally along the crossbeam guide rail (Y axis), the ram moves up and down along the horizontal slide rail (Z axis), and the worktable moves horizontally along the bed rail (X axis). Under the control of the CNC system, the machine tool can realize XYZW four-axis control and four-axis linkage.

The machine tool is widely used in the rough and fine processing of various complex parts such as plates, boxes, and frames in the machinery manufacturing industry. It can realize the four-axis linkage of the vertical boring and milling head horizontal (Y axis), vertical movement (Z axis), movable crossbeam lifting movement (W axis) and longitudinal movement (X axis) of the worktable. It can perform multi-process processing such as milling, boring, drilling, rigid tapping, reaming, and countersinking. It is mainly used for processing metal planes, curved surfaces and holes of large and medium-sized and heavy parts. It can be equipped with a variety of attachment heads. The attachment head can realize automatic indexing. One clamping can perform multiple processes such as milling, boring, drilling, reaming and tapping on the five surfaces of the workpiece. It can also process inclined surfaces, inclined holes, three-dimensional curved surfaces, holes inside part cavities and planes in narrow spaces.

The main parameters of the machine are as follows:

| Name | Units | Specifications | ||

| Worktable | mm | Worktable size | 3000×6000 | |

| mm | Distance between two columns (with protection) | 3700 | ||

| T | Workbench load-bearing capacity | 28 | ||

| mm | T-slot width | 14*28*200 | ||

| Feed | mm/min | X cutting feed speed range | 5-6000 | |

| mm/min | Y cutting feed speed range | 5-6000 | ||

| mm/min | Z cutting feed speed range | 5-5000 | ||

| m/min | X-axis rapid movement | 10 | ||

| m/min | Y-axis rapid movement | 10 | ||

| m/min | Z-axis rapid movement | 8 | ||

| m/min | W-axis rapid movement | 2 | ||

| Processing range | mm | X-axis travel | 6500 | |

| mm | Y-axis travel | 4200 | ||

| mm | Z-axis travel | Max. workpiece size is Z-axis travel + W-axis travel | 1250 | |

| mm | W-axis travel | 1600 | ||

| mm | Distance from spindle end face to workbench | 150-2650 | ||

Note: Machine parameters can be customized according to customer’s workpiece

If you have similar needs, please contact Shanghai ANTISHICNC: contact@antsmachine.com.

We not only have moving beam CNC gantry boring and milling machines, fixed beam CNC gantry boring and milling machines, but also ordinary boring and milling machines and CNC boring and milling machines. Our technical team will definitely be able to match you with the most suitable technical solution.