Overview of gear machining:

The key to gear processing is tooth profile processing.

At present, there are two kinds of tooth shape processing methods.

Cutting-free machining: Obtained by casting, hot rolling, cold extrusion, injection molding, and other methods.

Cutting: This is a processing method that utilizes a special cutting tool to produce multiple identical curved profiles on the surface of the workpiece blank. Because of the cutting process of gears can get a high degree of accuracy of tooth shape. Therefore, cutting is currently the main method of processing gears.

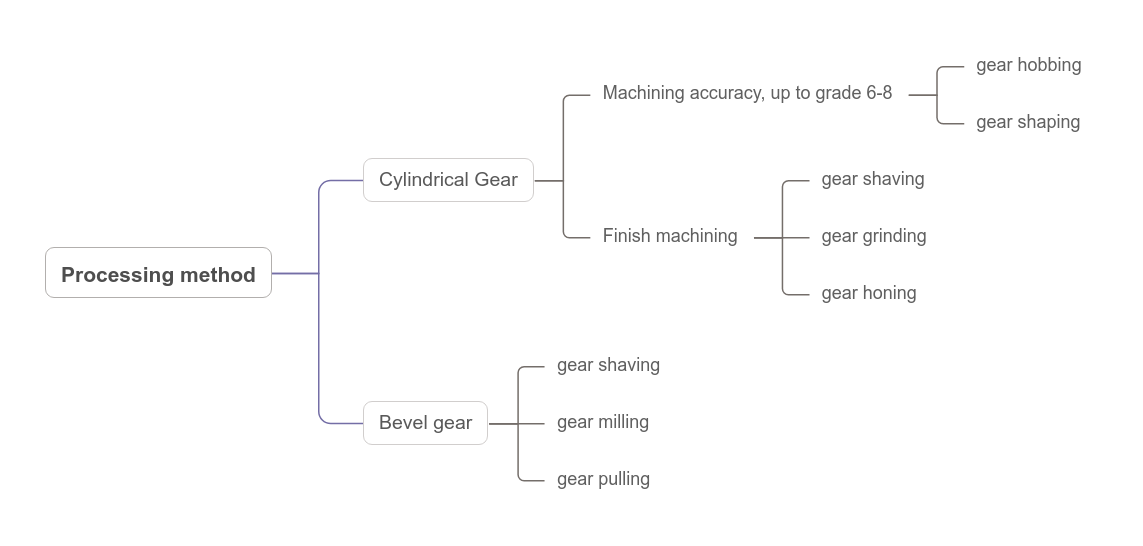

Common toothed parts:

Cylindrical gears, bevel gears, worm gears, splines.

Gear Processing Equipment.

Cylindrical Gear Machines: Gear Hobbing Machines, Gear Shaping Machines, Gear Cutting Machines

Bevel Gear Processing Machines: Gear Shaping Machines, Gear Milling Machines, Gear Pulling Machines

Introduction of different processing equipment:

| Equipment | Working principle | Application |

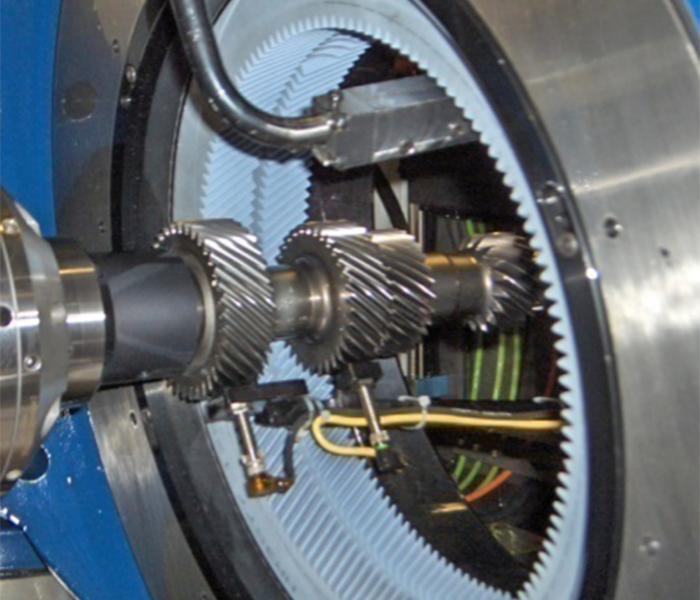

| Gear hobbing machine

|

Gear hobbing machine is a gear processing machine that utilizes gear hob to process cylindrical gears, worm gears and spline shafts according to the spreading method. The hob and the workpiece are equivalent to a pair of helical gears in a meshing state, when the hob rotates, the tooth shape is cut out on the workpiece. | It is mainly used for processing straight and helical cylindrical gears, and can also process worm gears and spline shafts with certain parameters. It is one of the most widely used equipments in gear processing and can efficiently process gears with high precision. |

| Gear shaping machine

|

Gear shaping machine is a gear processing machine for cylindrical gears according to the spreading method. During gear insertion, the gear shaper makes up and down reciprocating cutting motion, and at the same time makes relative rolling with the workpiece, and processes the tooth shape on the workpiece. | It is suitable for processing internal gears, double or multiple gears, sector gears and other gears that are difficult to be processed by hobbing machines. It has better performance in machining accuracy and surface quality, especially for some gears with special shape requirements are more suitable. |

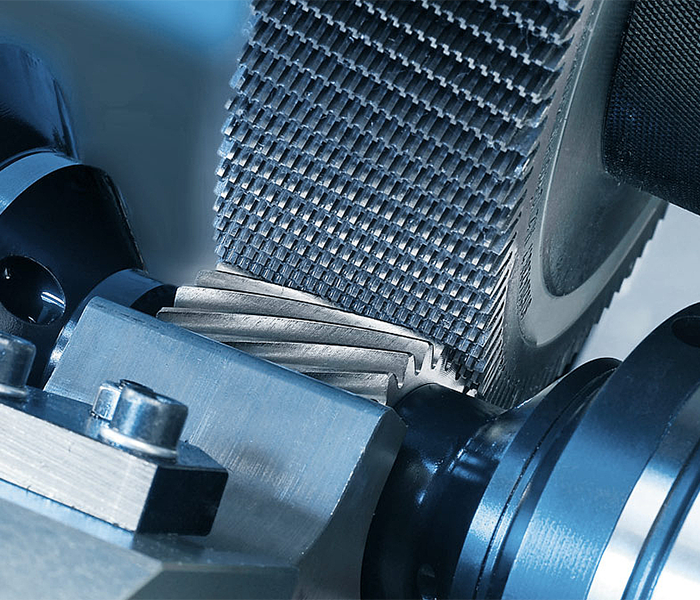

| Gear shaving machine

|

Gear shaving machine is a gear finishing machine tool, the use of shaving cutter and the cut gear wheel for free meshing movement, with the help of the relative slip between the two, from the tooth surface shaved down very fine chips, in order to improve the accuracy of the tooth surface. | Mainly used for gear finishing, in hobbing, gear insertion and other rough processing of the gear, through shaving can effectively improve the tooth shape accuracy, tooth to tooth accuracy and surface roughness, improve the transmission quality of the gear. |

| Gear grinding machine

|

Gear grinding machines use grinding wheels as cutters to grind the tooth surfaces of gears that have been machined in order to obtain high-precision gears. Depending on the grinding principle, there are different methods such as profile grinding and spreading grinding. The spreading method grinds the tooth surface by the spreading motion between the grinding wheel and the workpiece. | It is used for machining gears that require very high accuracy, such as gears in aerospace and precision machine tools. It can machine gears with high accuracy levels and can correct various errors generated in the pre-processing of gears. |

| Gear honing machine

|

Gear honing machine is a device that utilizes the relative motion between the honing wheel and the gear to be processed in the process of meshing to finish the gear tooth surface. Honing wheels are generally made of abrasives such as emery and bonding agents such as plastic. | Mainly used for gear finishing process, after honing gear, tooth surface roughness has been significantly improved, can effectively reduce the noise of gear transmission, improve the wear resistance and service life of gears. It is often used as the last finishing process after shaving or grinding. |

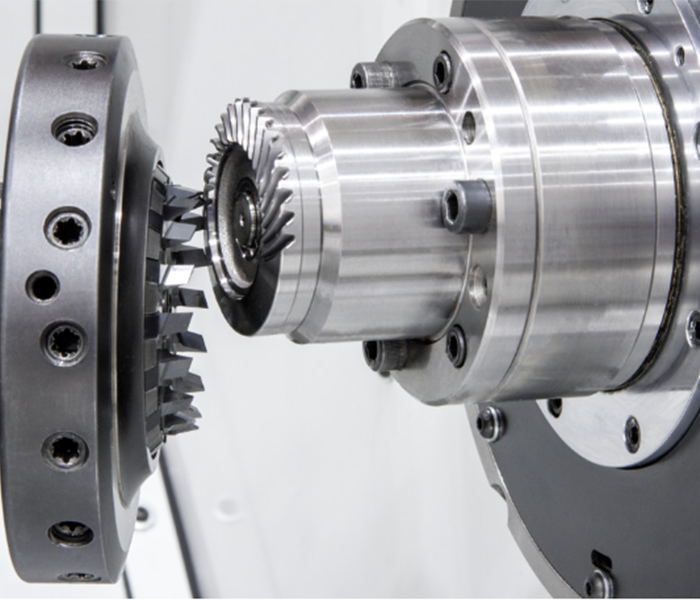

| Gear planning machine

|

Straight bevel gears are machined by the reciprocating linear motion of the planer knife and the intermittent rotary motion of the tooth blanks, based on the spreading method, which removes excess metal from the tooth blanks by the cutting edges of the planer knife, just as in the case of gear meshing. | Widely used in machinery manufacturing, such as automobile differential bevel gear processing; in aerospace for aircraft engines and other systems of high-precision bevel gear manufacturing; in the field of construction machinery, used in excavators and other equipment drive system bevel gear manufacturing; in shipbuilding, can be processed ship propulsion and rudder system bevel gear. |

| Gear milling machine

|

Gear blanks are processed using a milling cutter. The milling cutter rotates at high speed as the main motion, while the gear blank rotates slowly and moves in the direction of its own axis, and the blank is machined into a gear by milling tooth by tooth with the milling cutter. | Widely used in the field of machinery manufacturing. Commonly used in the processing of precision requirements are not extremely high cylindrical gears, such as ordinary gear reducer gear. It is also used in the transmission system of some small machines, such as toy machines, simple agricultural machines, etc. It can quickly and economically produce gears that meet the basic transmission requirements. |

| Gear pulling machine

|

It is used to machine gears by the relative motion of the broach and the tooth blank. A broach is a tool with a series of teeth whose shape and size match the shape of the teeth to be machined. When working, the broach moves in a straight line, cutting from one end of the tooth blank, and the teeth of the cutter sequentially remove excess material from the tooth blank, gradually forming the desired tooth shape. | It is mainly used for processing internal and external gears with high precision and complex shapes. It is widely used in the manufacture of automobile transmission gears and transmission gears for machine tools, and is capable of efficiently producing gears that meet the requirements of high precision and improving the quality and transmission performance of gears. |

Gear processing requires comprehensive consideration of material, precision, batch size and other factors, reasonable selection of technology and equipment, control of the parameters of each link, in order to produce high-quality gears to meet the needs of different mechanical transmission, to ensure the stable and efficient operation of mechanical systems.

If you have gear processing needs, welcome to contact the Shanghai Anticus team, we will have a dedicated person to provide you with solutions.

Please visit our website:www.antsmachine.com

Or email to: contact@antsmachine.com

Welcome to subscribe to our YouTube channel:

https://www.youtube.com/@antishicncmetalprocessingm9086/featured

Keywords: gears, gear machining, hobbing machine, metal forming