Those in the machinery industry know that CNC lathes are divided into CNC horizontal lathes and CNC vertical lathes. The main difference between the two lies in the orientation of the spindle. On a CNC horizontal lathe, the spindle is horizontal, and the workpiece rotates between the spindle chuck or centers. On a CNC vertical lathe, the spindle is vertical, and the workpiece rotates on a horizontal worktable. CNC horizontal lathes are highly versatile, suitable for machining various shaft and disc-shaped parts, ranging from micro to large, and have a high market share and greater demand. CNC vertical lathes, on the other hand, have exceptionally high load-bearing capacity, making them particularly suitable for machining heavy parts. The workpiece’s own weight does not cause bending deformation, resulting in better rigidity. Although CNC vertical lathes are more expensive and have relatively lower demand, they are particularly convenient for machining certain parts.

So, what are the main practical applications of CNC vertical lathes?

1. Energy and power industry: Processing flanges, gearbox housings, and hubs for wind power; processing turbine runner blade flanges, generator end covers, and rotor supports for hydropower; processing steam turbine/gas turbine cylinder blocks and large valve bodies for thermal power.

2. Transportation equipment manufacturing industry: Processing high-speed rail/train wheel hubs (wheels), locomotive drive gearboxes, and brake discs (brake discs) for the rail transit industry; processing large marine diesel engine parts, propeller hubs, and large slewing bearings for deck machinery for the shipbuilding and marine engineering industry.

3. Aerospace industry: Machining aircraft engine casings, turbine disks, and compressor disks; machining rocket engine casings/nozzles, and satellite propellant tank heads.

4. General heavy machinery and mold industry:processing excavator/tunnel boring machine slewing bearings, mining mill end covers, and hydraulic cylinder end covers for the mining and construction machinery industries; processing roll bearing seats for metallurgical equipment.

5. Chemical and general equipment industry:processing compressor/pump housings, processing papermaking machinery drying cylinders.

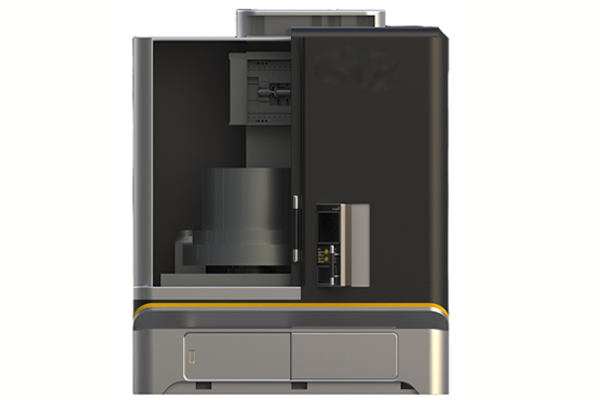

Recently, Shanghai ANTISHICNC received an inquiry from an overseas customer, asking if we had a CNC vertical lathe with a 500mm chuck diameter. The customer sent relevant drawings, and based on their requirements, we recommended our high-configuration VL78M CNC vertical lathe.

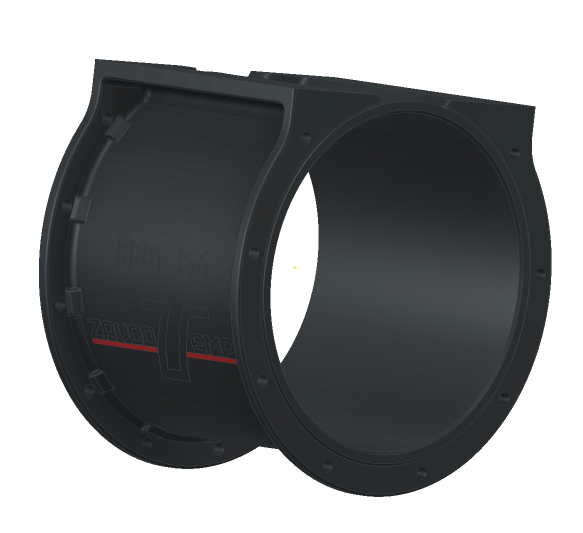

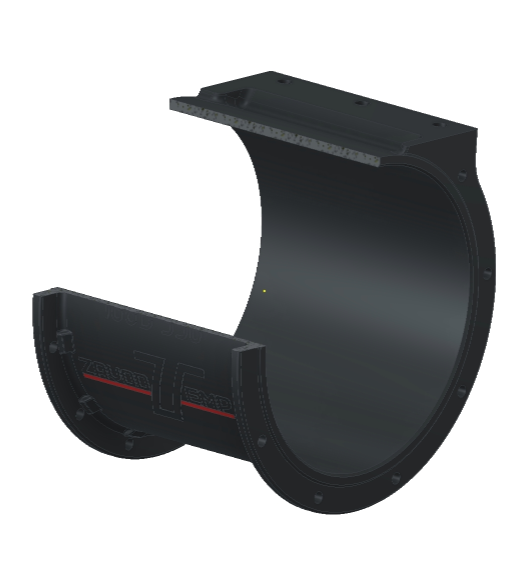

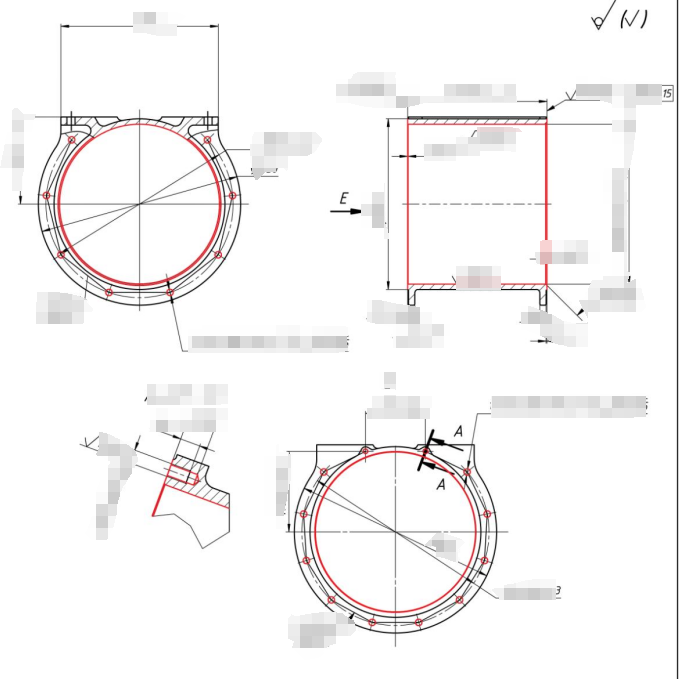

|

|

|

|

| Customer’s workpiece schematic diagram and drawings | |

Our VL78M CNC vertical lathes have the following main characteristics:

1. Widened columns can withstand full-stroke cutting loads.

2. The vertical axis starts the balancing system to ensure safety and reliability.

3. Japanese P-class high-load linear roller guide.

4. The large-nose spindle is equipped with Japanese P4-grade spindle bearings to ensure spindle rigidity and rotational accuracy.

5. The inner bed has a sloping surface, which optimizes chip removal.

6. The design is user-friendly and facilitates inspection and maintenance.

7. Heavy-duty bed, enhancing vibration resistance under heavy cutting loads.

Below are the specific technical parameters of this CNC vertical lathe.

| Parameters | Unit | VL78M | |

| Standard chuck diameter | inch | twenty one” | |

| Processing

ability |

Maximum slewing diameter of the bed frame | mm | Ф900 |

| Maximum cutting diameter | mm | Ф800 | |

| Maximum cutting length | mm | 800 | |

| Distance from chuck end face to tool post bottom face | mm | 800 | |

| spindle | Power (continuous/30 minutes) | kW | 15/18.5 |

| Maximum speed | r/min | 1-218

218-1200 |

|

| Rated/Maximum Output Torque | Nm | 1144/1888 | |

| End type | A2-11 | ||

| X-axis travel | mm | 450 | |

| Z-axis travel | mm | 800 | |

| X-axis rapid traverse speed | m/min | 18 | |

| Z-axis rapid traverse speed | m/min | 15 | |

| Dota | Power turret type | BMT65 | |

| turret power motor power | Kw | 5.5 | |

| Maximum speed of power cutting tools | rmp | 4000 | |

| turret motor torque | Nm | 26.3 | |

| Power tool interface | ER32 | ||

| Tool size |

External cutting tool dimensions | mm | 25×25 |

| Boring tool shank diameter | mm | Ф40 | |

| Maximum drilling diameter | Ф20 ( S45C ) | ||

| Maximum tapping diameter | M20 ( S45C ) | ||

| Machine tool weight | kg | 11500 | |

| Maximum load | kg | 600 (including chuck and other accessories) | |

| Machine tool appearance | mm | Please refer to the dimensions on the drawing. | |

| Electrical capacity | kVA | 40 | |

If you also need CNC vertical lathes, please feel free to contact Shanghai ANTISHICNC. We have professional engineers who can provide you with expert technical support.

Company email: contact@antsmachine.com

Keywords: lathe, manual lathe, CNC lathe, CNC vertical lathe, CNC horizontal lathe, CNC flat bed lathe, CNC slant bed lathe, CNC turning-milling compound