The so-called CNC machine tool, without a tool magazine is called a CNC milling machine, and with a tool magazine is called a machining center. It is also called CNC. CNC (CNC machine tool) is the abbreviation of Computer numerical control machine tool (Computer numerical control), which is an automated machine tool equipped with a program control system. The control system can logically process programs specified by control codes or other symbolic instructions, and decode them, so that the machine tool can move and process parts.

The so-called CNC machining center refers to a CNC machine tool equipped with a tool magazine, with automatic tool change function, and can perform multiple processes after clamping the workpiece once. The CNC machining center is a highly mechatronic product. After the workpiece is clamped, the CNC system can control the machine tool to automatically select and replace tools according to different processes, automatically set the tool, and automatically change the spindle speed and feed rate. It can continuously complete multiple processes such as drilling, boring, milling, reaming, and tapping. Therefore, it greatly reduces the workpiece clamping time, measurement and machine tool adjustment and other auxiliary process time, and has good economic effects for processing parts with complex shapes, high precision requirements, and frequent variety changes.

CNC machining centers are usually classified by the relative position of the spindle and the worktable, and are divided into horizontal, vertical and universal machining centers.

1) Horizontal CNC machining center: refers to a machining center with the spindle axis set parallel to the worktable, mainly suitable for machining box parts.

2) Vertical CNC machining center: refers to a machining center with the spindle axis set perpendicular to the worktable, mainly suitable for machining complex parts such as plates, discs, molds and small shells.

3) Universal CNC machining center (also known as multi-axis linkage machining center): refers to a machining center that can control the linkage change by machining the angle between the spindle axis and the rotary axis of the worktable to complete the machining of complex spatial surfaces. It is suitable for machining workpieces such as impeller rotors, molds, cutting tools, etc. with complex spatial surfaces.

CNC machining center is one of the most productive and widely used CNC machine tools in the world. It has strong comprehensive processing capabilities. After the workpiece is clamped once, it can complete more processing content and has high processing accuracy. For batch workpieces with medium processing difficulty, its efficiency is 5 to 10 times that of ordinary machine tools. In particular, it can complete many processing that ordinary equipment cannot complete. It is more suitable for single-piece processing with complex shapes and high precision requirements or small and medium-sized batch multi-variety production.

It concentrates the functions of milling, boring, drilling, tapping and thread cutting on one device, so that it has a variety of processing technology means. The CNC machine center is equipped with a tool magazine, which stores different numbers of various types of tools, which are automatically selected and replaced by the program during the processing. Ordinary milling machines and boring machines cannot compare with it. The CNC machining center machine tool itself has high precision and has obvious advantages in the processing of complex parts and small batch parts. It can not only ensure the processing quality, but also improve the production and processing efficiency.

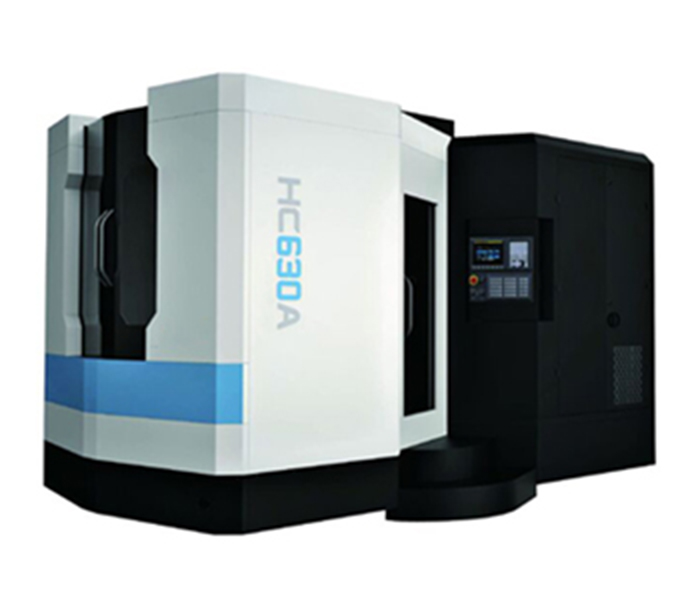

The HC series horizontal machining center of ANTISHI Machine Tool is a horizontal machining center designed and developed by ANTISHI Machine Tool on the basis of absorbing advanced machine tool design concepts at home and abroad. The machine adopts a large-span guide rail design, with good overall rigidity and strong load-bearing capacity. It has a CNC turntable and is suitable for processing polyhedrons such as car body parts, machine tool bases, polygons, etc. One clamping can complete processes other than rough and fine processing such as milling, boring, drilling, and tapping. The base, column, slide, and spindle box of this machine tool are all made of high-quality cast iron HT300.

The large foundation section adopts a dense rib design and uses finite element analysis to ensure high bending and torsional rigidity, so that it has a higher natural frequency and improves vibration resistance.

The three-axis hard rail (quenching) meets the technical performance requirements. The amount of cutting is large and the precision requirements are high. After secondary aging treatment, the internal stress is eliminated. It has the characteristics of good overall rigidity, good vibration absorption performance, and good seismic performance.

It is widely used in the processing of box parts, shell parts, and disc parts in the automotive, mold, and machinery manufacturing industries. After the parts are clamped once, they can be processed through multiple processes such as milling, boring, drilling, expanding, reaming, tapping, etc., with high precision, high degree of automation, high reliability, high degree of mechatronics, simple operation and beautiful overall appearance.

Shanghai ANTISHI provides a variety of CNC machining centers to choose from, such as vertical machining centers VMC650, 850, 1060, etc., horizontal machining centers HLC series, etc.If you have any needs, please contact Shanghai ANTISHI!