Today, Two surface grinders from Shanghai ANTISHICNC were exported to the Russian market. Shanghai ANTISHICNC further consolidated and expanded its international market share by exploring emerging markets, increasing product added value, and improving its after-sales service system.:

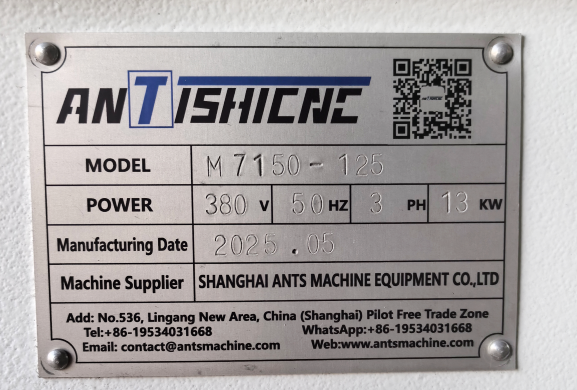

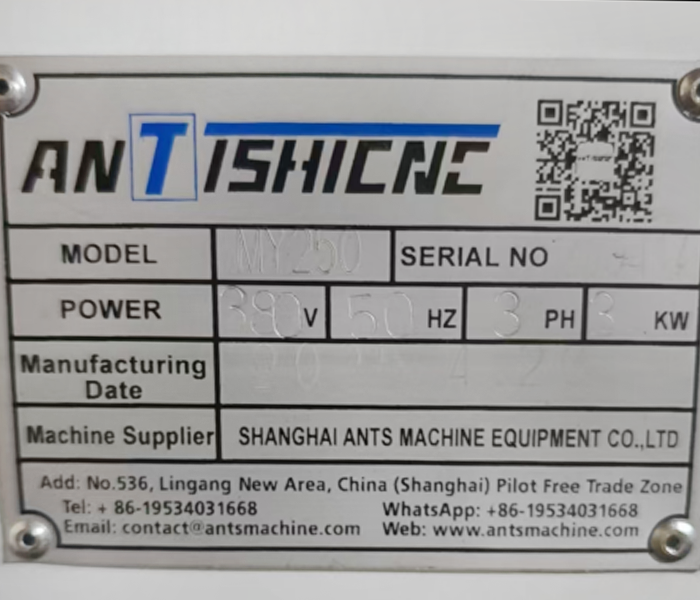

| Producer | Shanghai ANTS Machine Equipment Co.,LTD | Brand | ANTISHICNC | Origin country | Shanghai, China |

| Product Name | Surface Grinding Machine | Model No. | M7150

MY250 |

Export Country | Russia |

| Customer Introduction | The Russian customer is one of the Russian automobile manufacturers, mainly producing cars and light commercial vehicles. In the automobile manufacturing process, the processing of many parts such as engine cylinder block, crankshaft, gearbox housing, etc. requires surface grinders to ensure high-precision flatness and dimensional accuracy to ensure the assembly accuracy of parts and the overall performance of the car. | ||||

| M7150 Equipment Application | M7150 surface grinding machine

Structural features: horizontal axis rectangular table structure, the machine tool hydraulic system adopts bed oil pool, the longitudinal movement of the worktable is driven by a vane oil pump, and the operating box and other integrated hydraulic control units are compact and easy to maintain. The grinding head has hydraulic automatic feeding and manual feeding for transverse feeding, and the vertical movement has a fast lifting mechanism and manual feeding. Main use: suitable for various mechanical rough grinding, widely used, easy to operate, and high grinding efficiency. It is mainly used for grinding around the grinding wheel, and can also be used to grind the vertical surface of the workpiece. |

||||

| M7150 Equipment Picture |

|

||||

| MY250 Equipment Application | MY250 surface grinding machine

Structural features: Based on the M250 manual surface grinder, the manual longitudinal movement mechanism of the worktable is converted into a hydraulic system, which is composed of a motor quantitative pump, and the system pressure is adjusted by a relief valve. The main mechanical valve is a special valve for the grinder with multiple functions. Digital display instruments can be installed to accurately control the feed amount, and permanent magnetic chucks or electromagnetic chucks can be equipped according to customer needs. Main use: It is a high-precision surface grinder, suitable for processing scenarios with high requirements for workpiece surface accuracy. |

||||

| MY250 Equipment Picture |

|

||||

If you want to order the same product, please open the link as below and contact with shanghai ANTISHICNC team!