A Bolivian customer came to Shanghai Antis. The customer is mainly engaged in the processing of non-ferrous metals (copper, bronze and brass), providing bars, valves, connectors and other products. Previously, the customer consulted our company to purchase a circular saw machine to cut brass rods. This time, he hoped to customize a dual-spindle CNC machine tool to process stainless steel. After receiving the customer’s inquiry, the sales team of ANTISHI confirmed their processing requirements with the customer as soon as possible. And confirmed other relevant processing information with the customer.

Customer processing technology and stainless steel parameters:

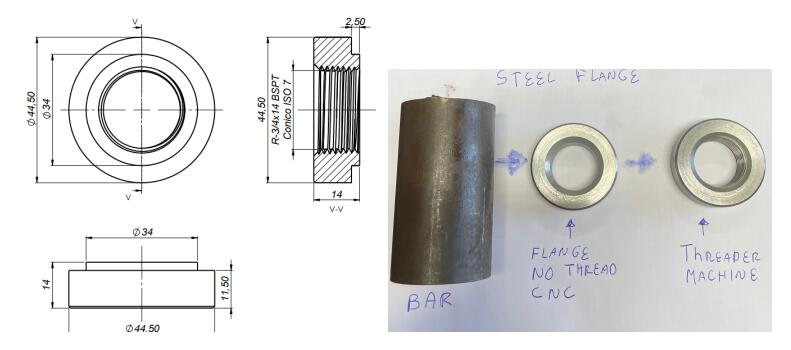

1 After cutting by circular saw machine, the stainless steel size is 44.5mm diameter and 11.5mm height.

2.The processing sequence is shown in the figure. First, drilling is required. The diameter of the drilling is 34mm, and a CNC pipe thread machine is required. Secondly, the outer circle width of the turning stainless steel is 10.5mm and the depth is 2.5mm. In addition, the customer is very strict about production efficiency. So choose to use dual-spindle CNC machine tools.

After confirming the relevant information with the customer, the Shanghai Antis sales team tailor-made a technical solution suitable for the customer’s processing requirements. After review by the technical team, the technical solution and quotation of the CNC dual-spindle machine tool were provided to the customer.

The dual-spindle CNC machine tools produced by Shanghai Antis are equivalent to two high-precision CNC machine tools equipped with automatic loading and unloading devices, which are suitable for workpieces processed in two sequences. Energy saving, high efficiency, and labor reduction. It is very suitable for the production requirements of customers for high-efficiency processing. It can not only meet the customer’s drilling 34mm, but also quickly change the tool for turning.

Product advantages of ANTISHICNC dual-spindle CNC machine tools:

1. There are four models of double-spindle tool arranging machine, double-spindle single-turret, double-spindle double-turret, double-spindle single-turret and single grinding head.

2. Different configurations can be selected according to the workpiece processing requirements, and any combination of turning, milling, drilling, grinding and other processes can be realized.

3. Guarantee the qualified rate of the workpiece. Equipped with loading and unloading machines suitable for workpieces to form an automatic production line.

4. One person can watch multiple automatic lines. At the same time, an automatic inspection machine can also be selected to detect the size of the workpiece online and realize real-time tool compensation to ensure the qualified rate of the workpiece.

5. Conducive to chip removal. Equipped with the function of flushing after the spindle and separate flushing of each tool post, which is beneficial to chip removal.

6. Password detection function. The fixture platform is equipped with a 3-hole air tightness detection function to ensure that the workpiece is clamped in place.

Product details

The customer is very satisfied after receiving the technical solution and quotation. As a leading manufacturer of industrial lathe machinery and machine tools in China, Shanghai Antis has 20 years of experience in machine tool production. The Shanghai Antis sales team adheres to the principle of being responsible to customers and will always provide customers with the best solution.

If you have any questions or needs, please contact the Shanghai ANTS sales team !