CNC gear hobbing machine is an advanced gear processing machine tool that operates according to the principle of the generating method. The gear hobbing cutter and the workpiece are similar to the meshing transmission of staggered axis helical gears. The CNC system accurately controls the rotation of the hobbing cutter, the rotation of the workpiece, and the feed movement of the hobbing cutter along the axial direction of the workpiece, thereby cutting out the involute tooth shape. It has many excellent characteristics and high processing accuracy. With the help of CNC technology, it can reach the 6th level or even higher precision level; the processing efficiency is outstanding, and the automated multi-axis linkage mode greatly reduces the auxiliary time; the processing range is wide, whether it is spur gears, helical gears, herringbone gears and other types of cylindrical gears, or worm gears, sprockets and other special gears can be processed; it has strong adaptability, and only needs to replace different hobs and adjust the CNC program to easily cope with gear processing tasks with different modules, numbers of teeth, helix angles and other parameters.

CNC gear hobbing machines are widely used in many fields:

Automobile manufacturing:used to process various gears in automobile transmissions, differentials and other components, which require high precision and quality of gears.

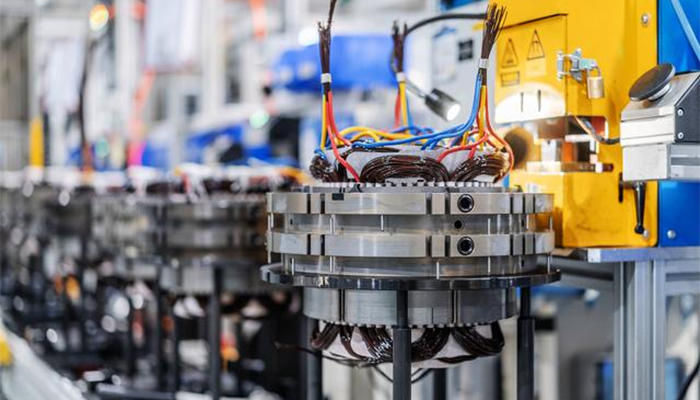

Machinery manufacturing:used in machine tools, engineering machinery, mining machinery and other industries to process various transmission gears to ensure the normal operation of mechanical equipment.

Aerospace:Processing high-precision gears in aircraft engines, helicopter transmission systems, etc., which requires extremely high reliability and performance of gears.

Shipbuilding:used to process large gears in ship propellers, gearboxes and other components, which require high processing accuracy and load-bearing capacity.

| Automobile manufacturing | Machinery manufacturing |

|

|

| Aerospace | Shipbuilding |

|

|

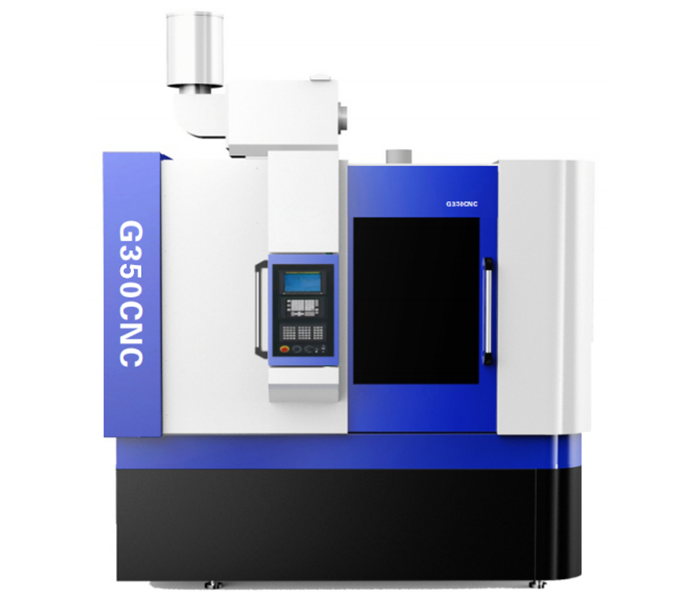

G350CNC CNC Gear Hobbing Machine

G350CNC is a six-axis CNC, four-axis linkage CNC high-speed gear hobbing machine. The six CNC axes are:

A-tool holder angle adjustment movement, B-hob spindle rotation, C-table rotation movement, X-radial feed movement, Y-tangential feed movement, Z-axial feed movement. Each CNC motion axis of the machine tool is driven by an independent AC servo motor, and the “electronic gearbox (EGB)” is used to achieve indexing movement and differential compensation to complete the processing of various gear parts using the development method.

| Items | Unit | G350CNC |

| Max workpiece diameter | mm | 350 |

| Max workpiece modulus | mm | 6 |

| Max axial travel (Z-axis displacement) | mm | 300 |

| Range of machining teeth | 6-400 | |

| Max hob diameter × length | mm | 120×200 |

| Worktable surface diameter | mm | 300 |

| Max rotation angle of tool holder | ±45° | |

| Distance from hob center to worktable center | mm | 35-265 |

| Distance from hob center to worktable surface | mm | 200-590 |

| Distance from top spindle end face to worktable surface | mm | 280-750 |

| Y-axis tangential travel | mm | 180 |

| Max spindle speed (B-axis) | r/min | 1250 |

| Max worktable speed (C-axis) | r/min | 115 |

| Max X-axis rapid movement | mm/min | 2000 |

| Max Z-axis rapid movement | mm/min | 2000 |

| Max Y-axis rapid movement | mm/min | 1000 |

| CNC axis linear coordinate resolution | mm | 0.001 |

| CNC axis rotary coordinate resolution | 0.001° | |

| Total machine power | KW | 57 |

| Total weight of main machine | KG | About 9500 |

| Machine tool peripheral dimensions (length × width × height) |

mm | 2970×1830×2880 |

If you also have automated gear processing needs, or need similar equipment, please consult Shanghai ANTISHICNC, we will provide you with professional advice! Please contact contact@antsmachine.com

Keywords: CNC gear hobbing machine, Automated gear processing, Automobile manufacturing, Machinery manufacturing